Connecting tool of motor testing platform

A motor testing and bench technology, which is applied in the direction of the measuring device casing, etc., can solve the problems that the motor test bench cannot be used to detect motors of different capacities, and the vibration of the motor test bench is large, so as to improve stability and safety , easy and fast replacement, guarantee the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

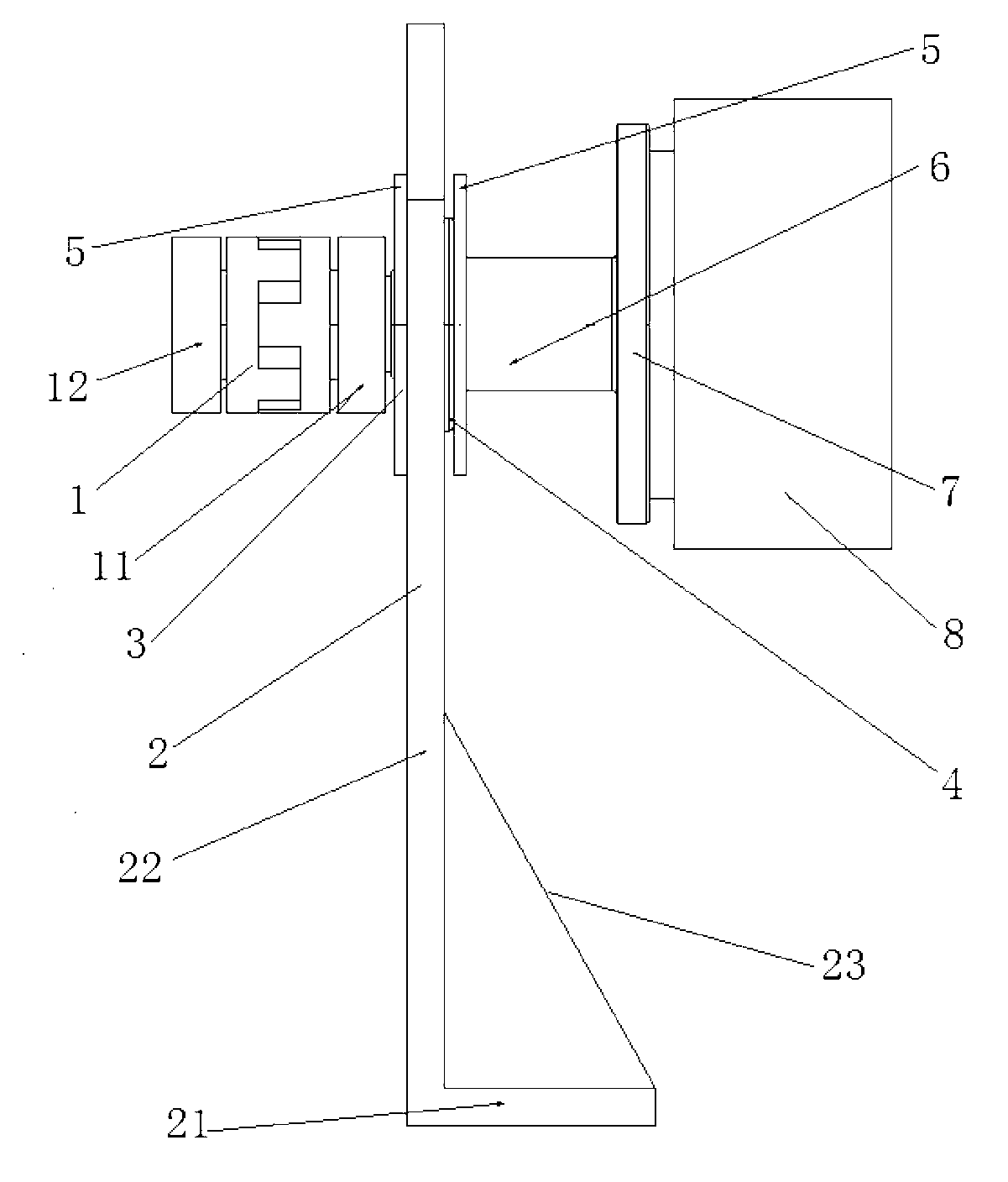

[0013] Examples such as figure 1 As shown, a motor test bench connection tool includes a first coupling 8, a flange 7 and a stepped shaft 6 that are sequentially connected to a measuring and control machine; a connecting portion 3 connected to the stepped shaft connection 6 is fixed at Fixed bracket 2. The other end of the connecting portion 3 is connected to the second coupling 1, and the second coupling 1 is connected to the motor under test; the second coupling 1 is divided into a fixed end 11 and a detachable movable end 12. Terminal 12 is connected to the motor under test.

[0014] The connecting portion 3 includes a bearing 4 connecting the stepped shaft 6 and the second coupling 1 and a bearing end cover 5 for fixing the bearing 4. The bearing end cover 5 is fixed on the fixing bracket 2 by bolts for fixing the bearing 4.

[0015] The fixing bracket 2 includes a supporting plate 21 and a bearing fixing bracket 22. The supporting plate 21 and the bearing fixing bracket 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com