Liquid crystal module testing device

A liquid crystal module and testing device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of large errors and low test accuracy, and achieve the effects of narrowing the adjustment range, convenient adjustment, and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

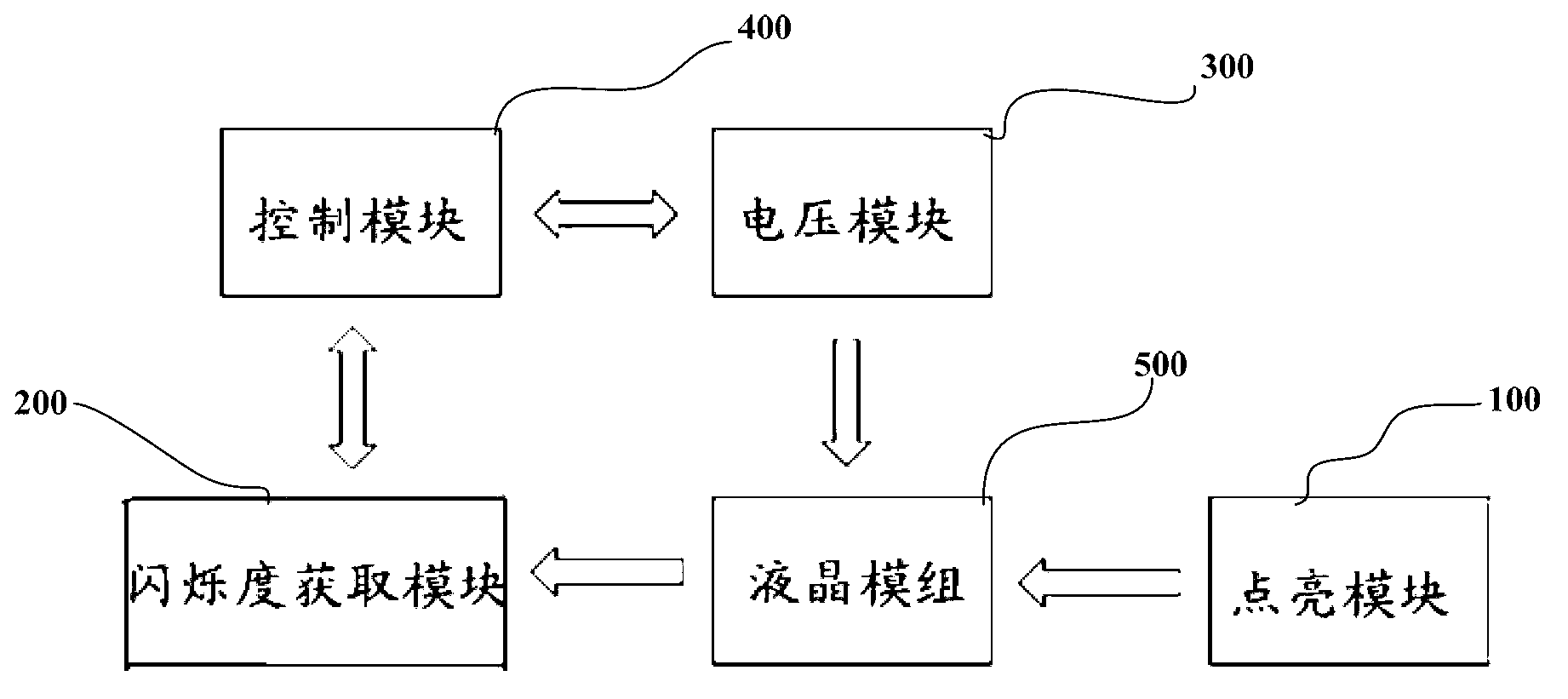

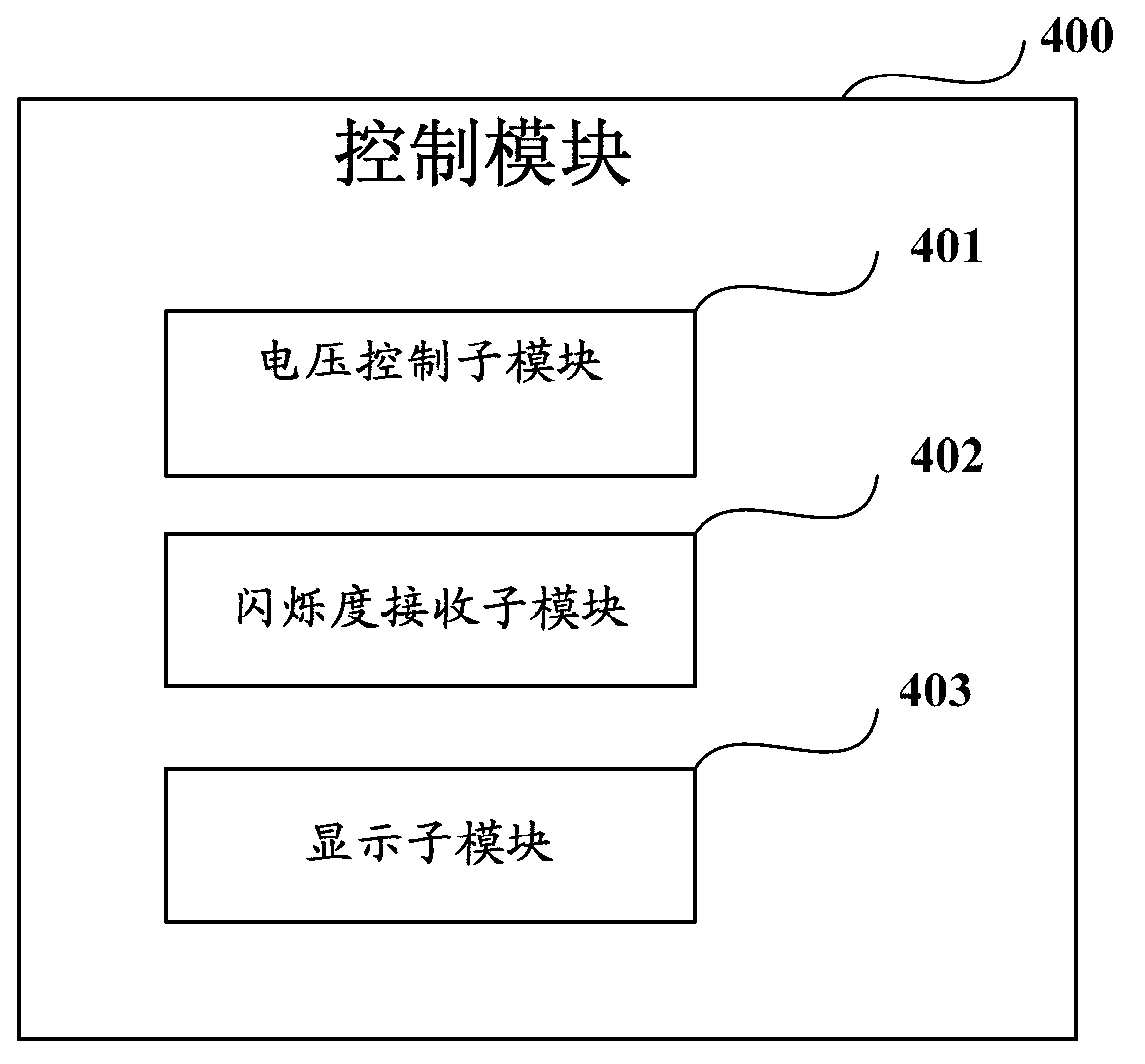

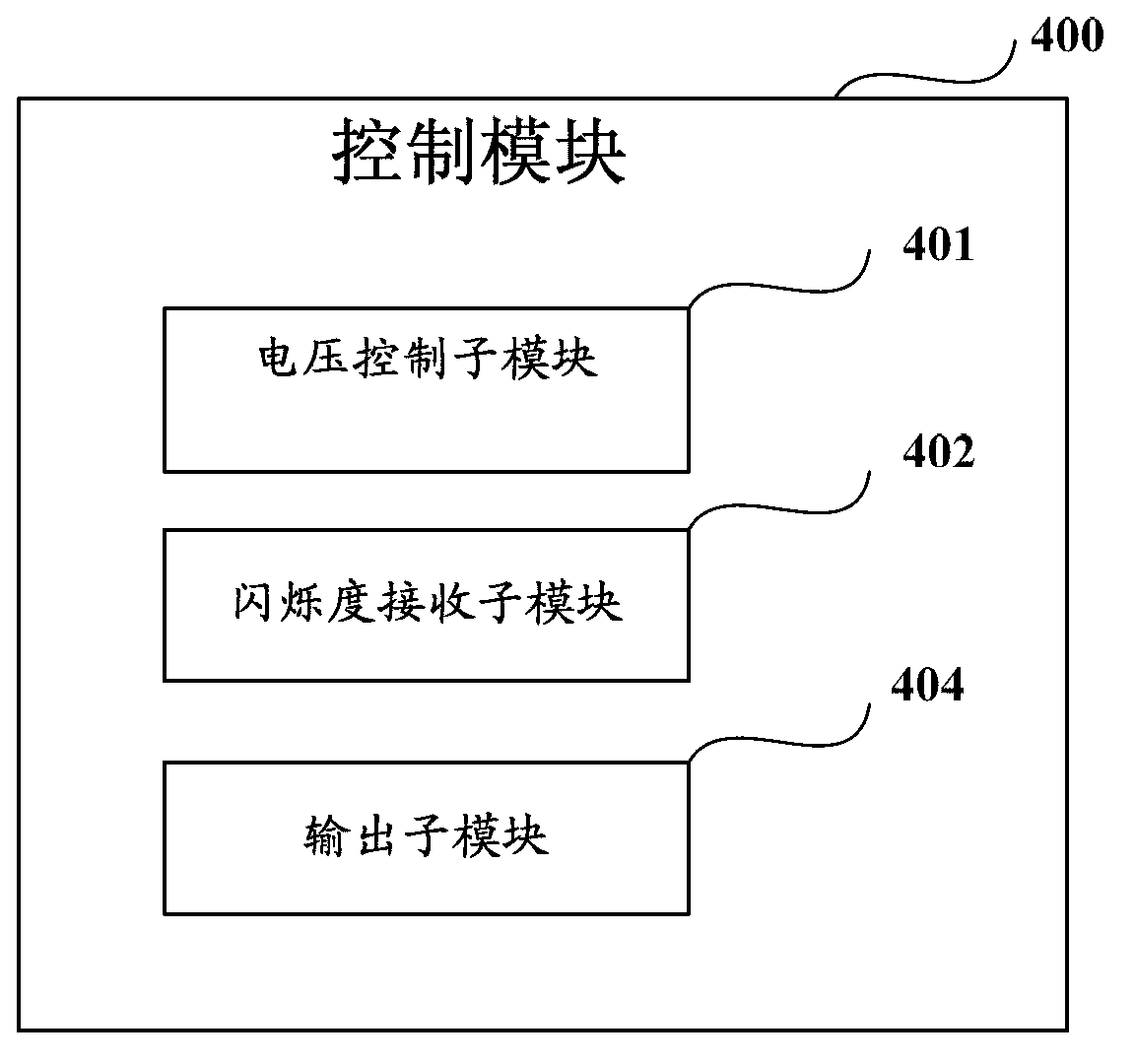

[0029] Such as figure 1 As shown, it is a schematic structural diagram of the test device of the first embodiment of the present invention. The test device of this embodiment includes a lighting module 100, a flicker acquisition module 200, a voltage module 300 and a control module 400, and the liquid crystal module 500 is used as the measuring unit. The lighting module 100 is used to connect with the liquid crystal module 500 to be tested to light the liquid crystal module and input a test picture. The scintillation acquisition module 200 is used to connect with the liquid crystal module 500 to be tested to acquire the scintillation of the liquid crystal module. The voltage module 300 is used to connect with the liquid crystal module to be tested and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com