Control method for realizing long-distance position detection by combination of encoder and limit

A control method and encoder technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as long waiting distance, data loss, and reduced production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

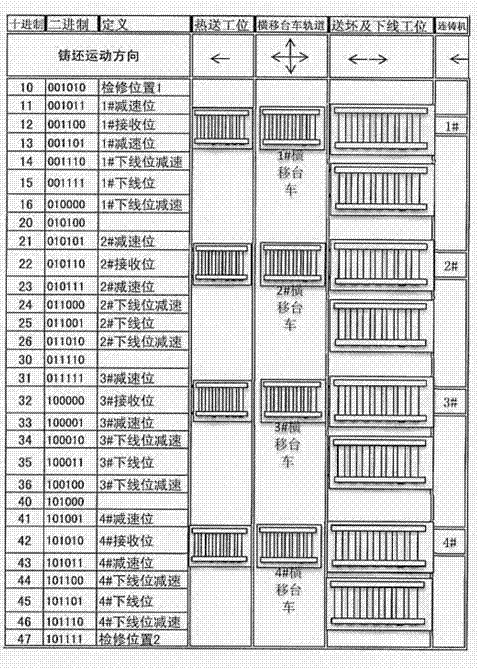

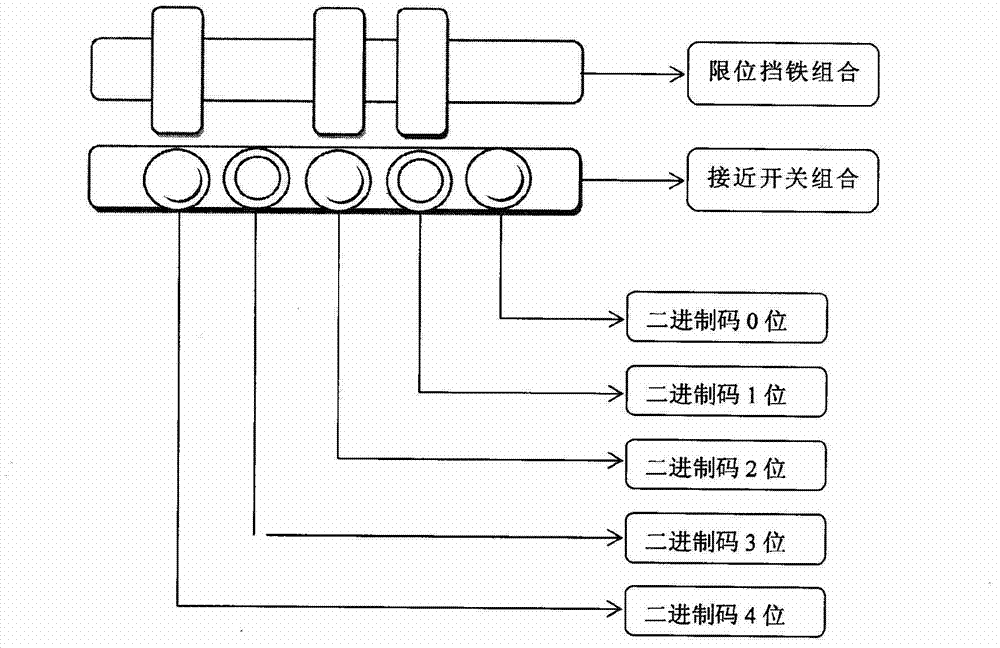

[0040] The control method of the present invention adopts the mechanical limit combination coding method to realize the identification and detection of multiple work points:

[0041] 1) Combined limit: The armature that triggers the limit combination signal is fixed on the track, and the limit combination is installed on the vehicle running on the track; the combined limit is mainly used to define and distinguish the position of the vehicle interval.

[0042] Realized by this method: the mechanical limit is triggered in an orderly manner, forming a series of codes that change regularly, and the arrangement is regular (after the code is converted to decimal): the mantissa of the inspection digit is 0; the mantissa of the deceleration digit is: 1, 3, 4, 6; Stop bit mantissa: 2, 5. The tens digit is used to distinguish the range of the unit or control system, and the ones digit is used to distinguish the position function or the specific position of the interval.

[0043] 2) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com