Film-cutting machine structure

A scribing and sliding film technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of uneven force on the blue film boundary, high defect rate, and inability to ensure that the wafer ring die is all tight, etc. problem, to achieve the effect of reducing die extrusion damage, improving yield and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

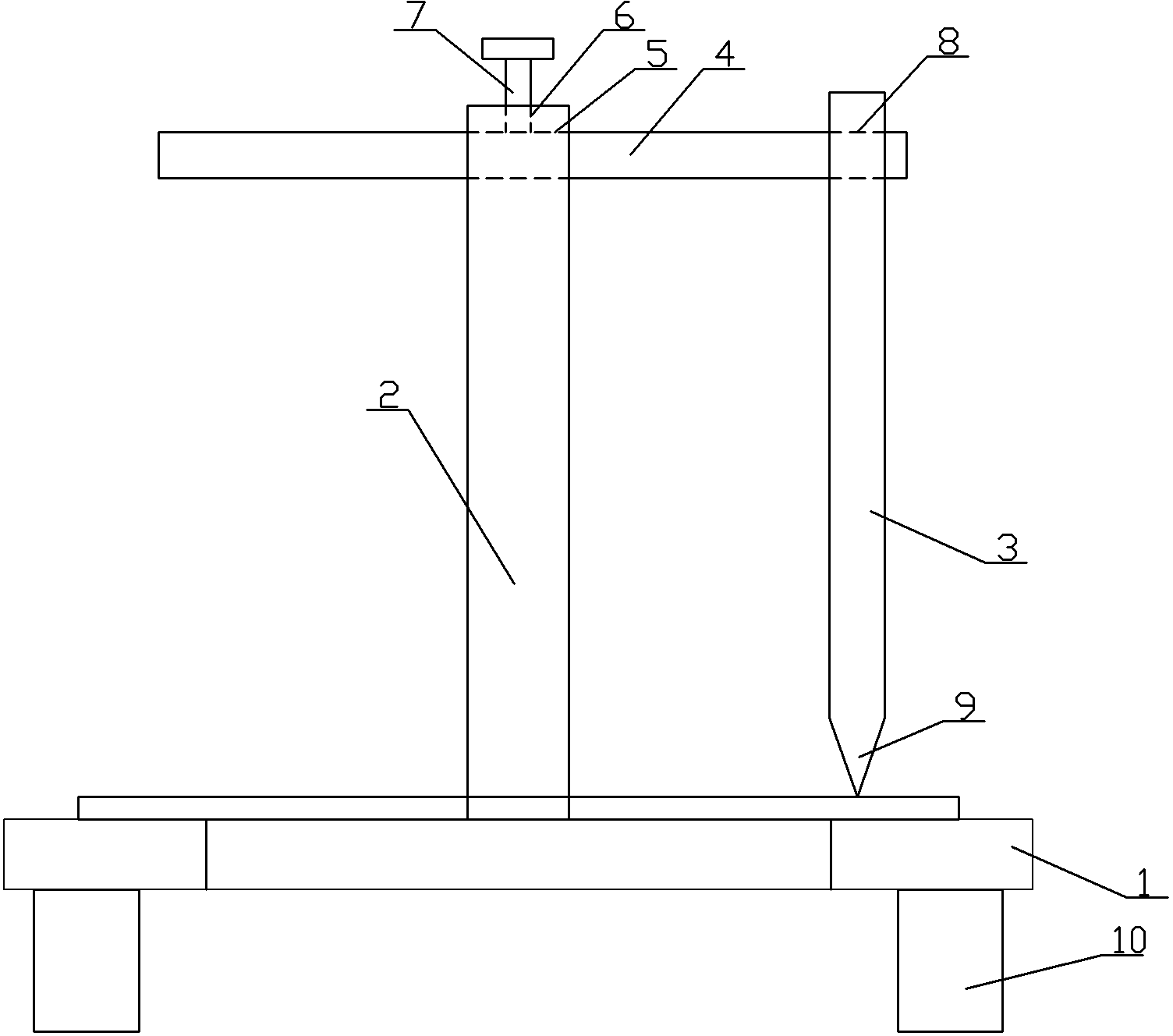

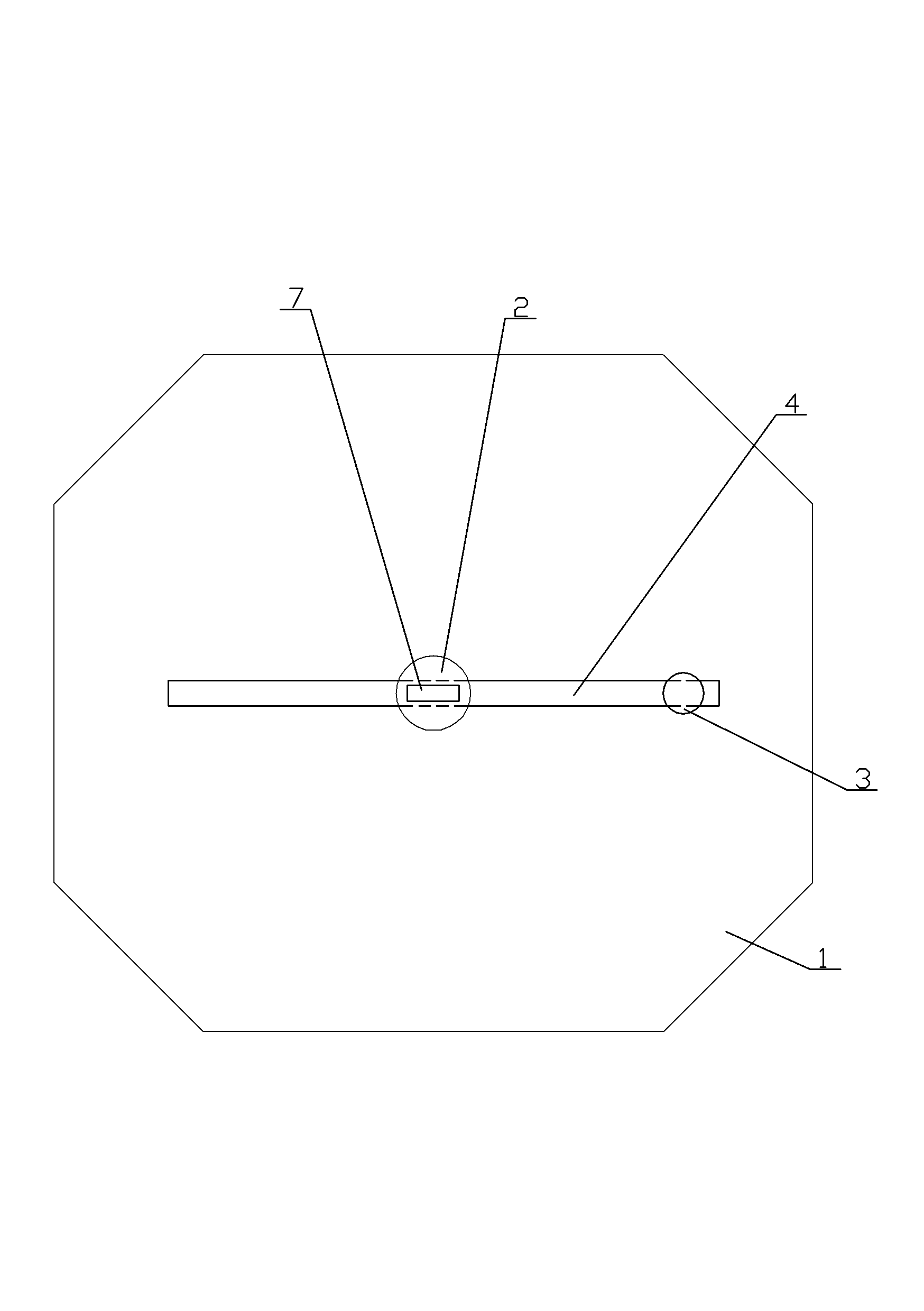

[0009] See figure 1 , figure 2 , which includes a base 1, a central shaft 2, the central shaft 2 is vertically inserted in the center of the base 1, it also includes a synovial knife 3, a synovial knife horizontal shaft 4, and the upper end of the central shaft 2 is provided with a through radial hole 5. The horizontal axis 4 of the synovial film knife runs through the radial hole 5 and then is arranged parallel to the plane of the base 1. There is a vertical limit threaded hole 6 in the center of the top of the central shaft 2, and the limit threaded hole 6 is connected to the radial hole 5. The limit screw 7 is threadedly connected to the limit threaded hole 6, and the lower end of the limit screw 7 is tightly pressed against the horizontal axis 4 of the synovial knife. The synovial knife 3 is arranged perpendicular to the plane of the base 1. The upper end of the film knife 3 radially positions the hole 8 , and the knife head part 9 of the synovial film knife 3 faces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com