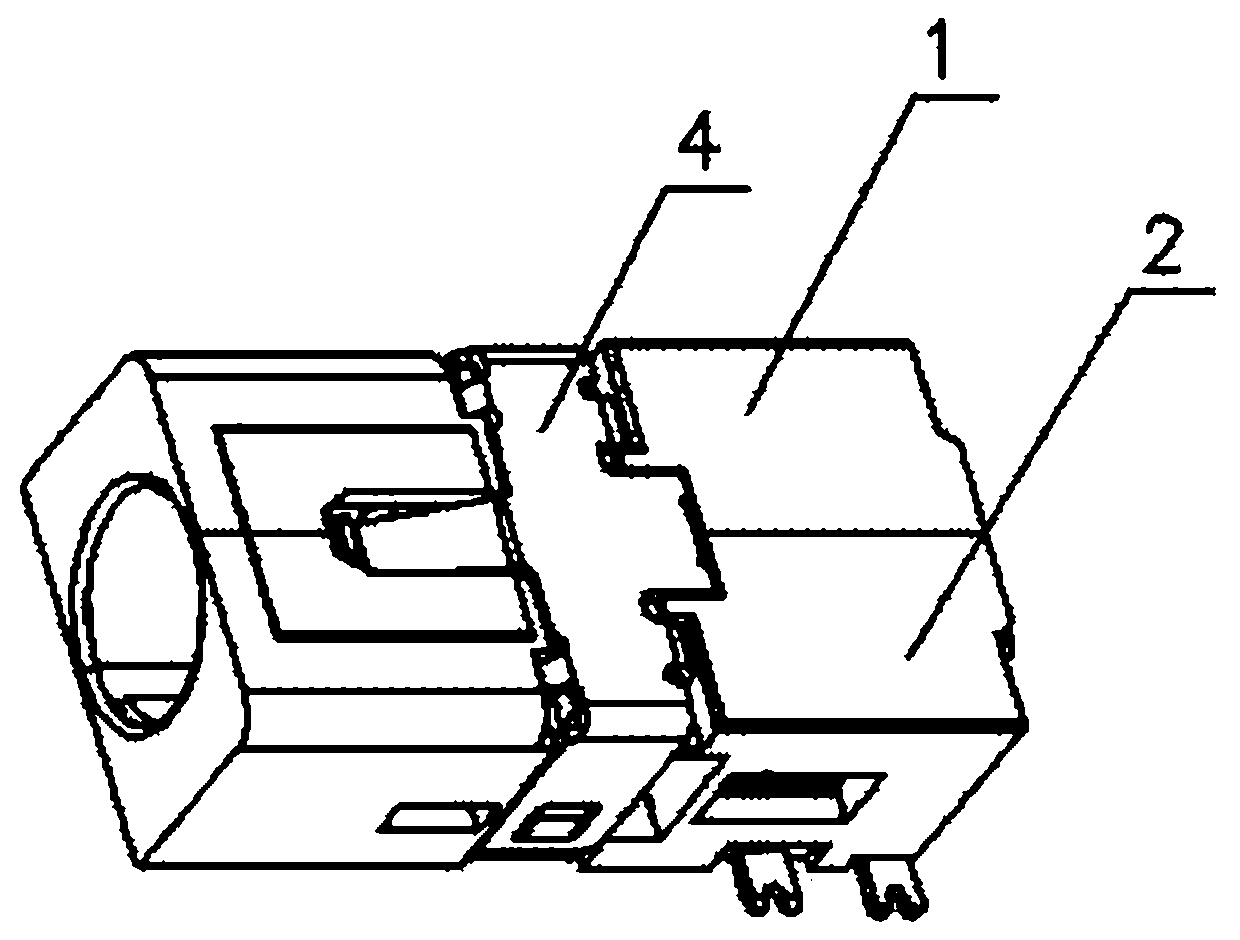

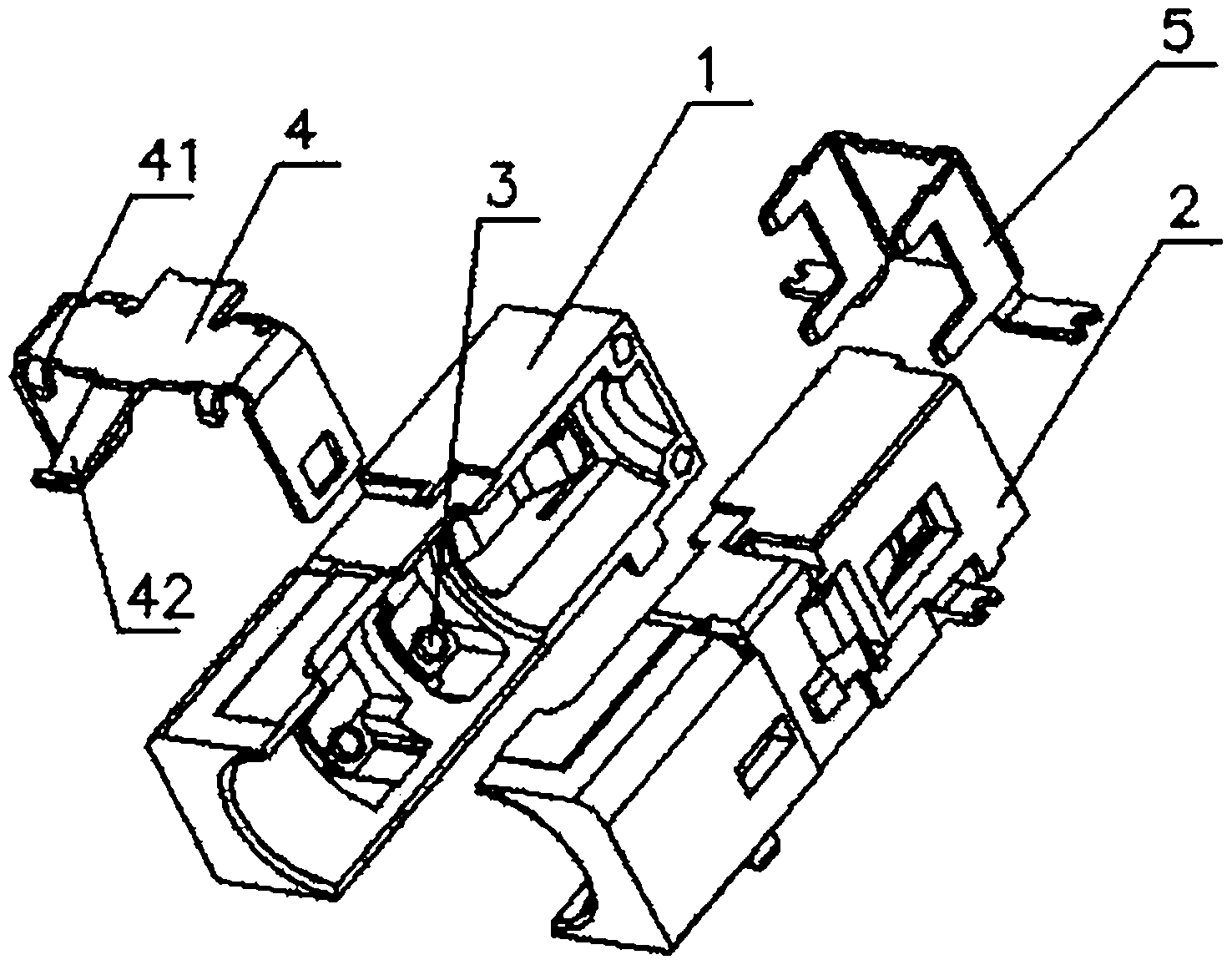

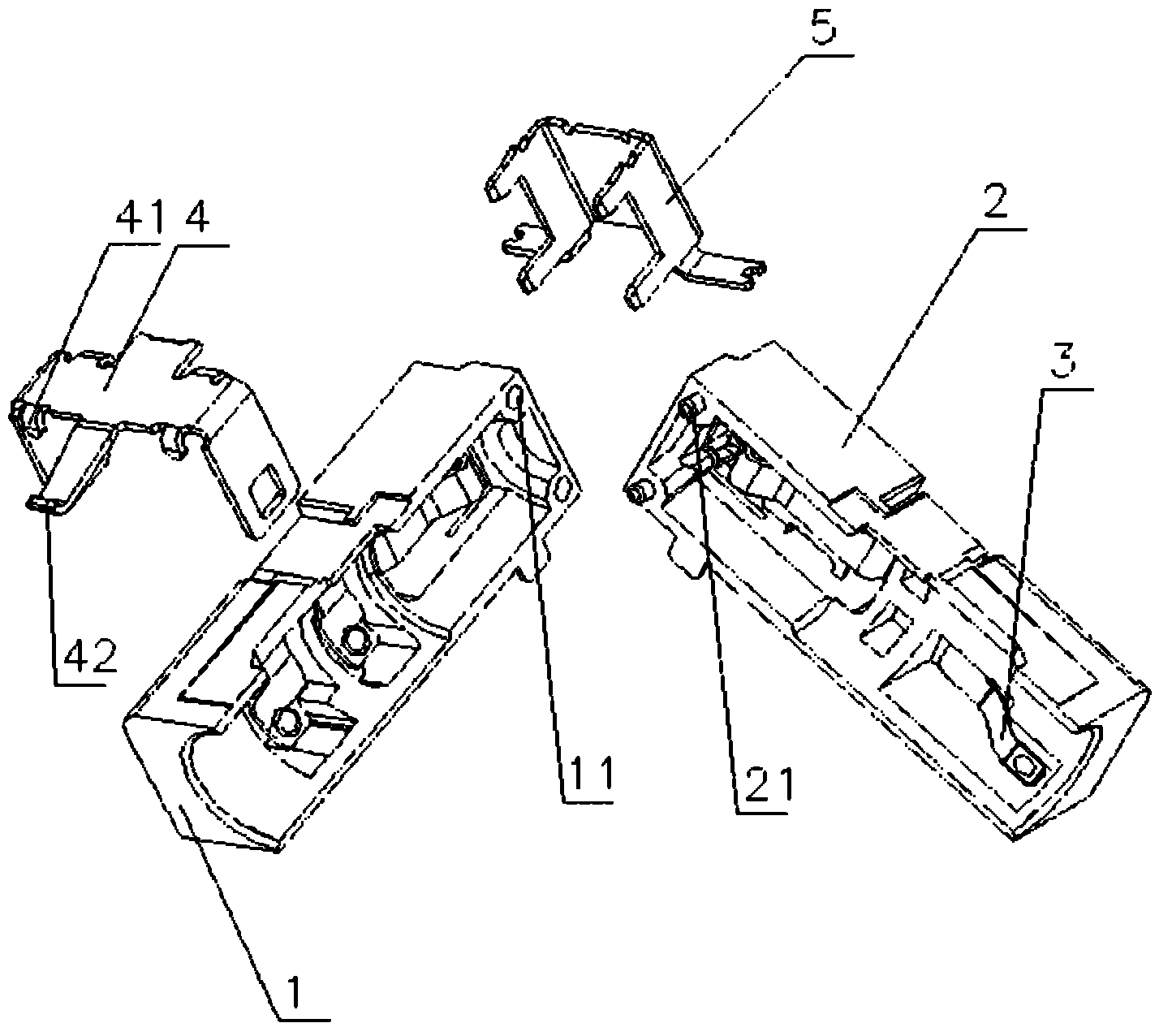

Headphone jack connector

A technology for earphone sockets and connectors, which is applied in the direction of connection, parts of connection devices, contact parts, etc., can solve problems such as poor contact, difficult manufacturing, and difficult assembly, so as to ensure the stability of use, reduce assembly processes, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: An earphone socket connector, including plastic parts and at least one elastic contact piece 3 (according to the functional requirements of the earphone socket, the number of contact pieces 3 can be more), the plastic parts include first, second Plastic parts 1 and 2, the first and second plastic parts 1 and 2 are fastened and connected, the opposite side walls at one end of the first and second plastic parts 1 and 2 are structurally symmetrical semi-cylindrical concave arc surfaces, and the contact piece 3 is integrally formed Inside the first and second plastic parts 1 and 2, the tail end of the contact piece 3 protrudes to the outside of the first and second plastic parts 1 and 2, and the shrapnel of the contact piece 3 extends to the ends of the first and second plastic parts 1 and 2. The outer side of the concave arc surface is also provided with a balance sheet 4, which is fixedly sleeved on the outer walls of the first and second plastic parts 1 and 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com