Single salient pole of motor sector salient pole rotor and assembly method of single salient pole

A salient pole rotor, a single technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of narrow space for reserved leads, difficult wiring, overall ventilation and heat dissipation of the motor To reduce the difficulty of machining, to facilitate installation and processing, and to achieve high electrical and mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

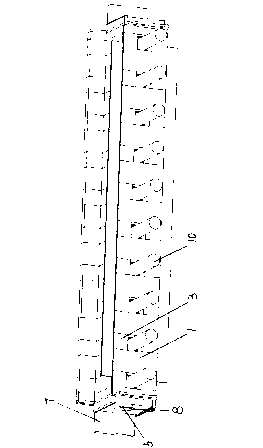

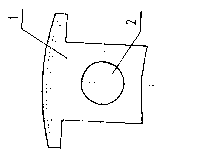

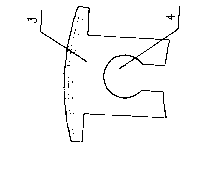

[0027] A single salient pole of a sector-shaped salient pole rotor of an electric motor, including a mandrel 5, a winding 11, a first group of salient pole rotor punches 1 and a second group of salient pole rotor punches 3, which are arranged at equal intervals on the mandrel 5 There are threaded through holes 6, a first mandrel through hole 2 is provided on the first group of salient pole rotor punches 1, and a second mandrel through hole with a notch is provided on the second group of salient pole rotor punches 3 4. On the mandrel 5, the first group of salient pole rotor punches 1 and the second group of salient pole rotor punches 3 are alternately pierced. The gaps provided on the second group of salient pole rotor punches 3 are the The threaded through-holes 6 provided at equidistant intervals on the 5 are correspondingly provided, and one end of the double-ended screw 10 passes through the gap provided on the second group of salient pole rotor punches 3 and is screwed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com