Autoanalyzer

A technology of automatic analysis device and analysis unit, which can be used in measurement devices, analysis materials, sampling devices, etc., and can solve problems such as inability to reach the liquid level, formation of films, and changes in electrostatic capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below using the drawings.

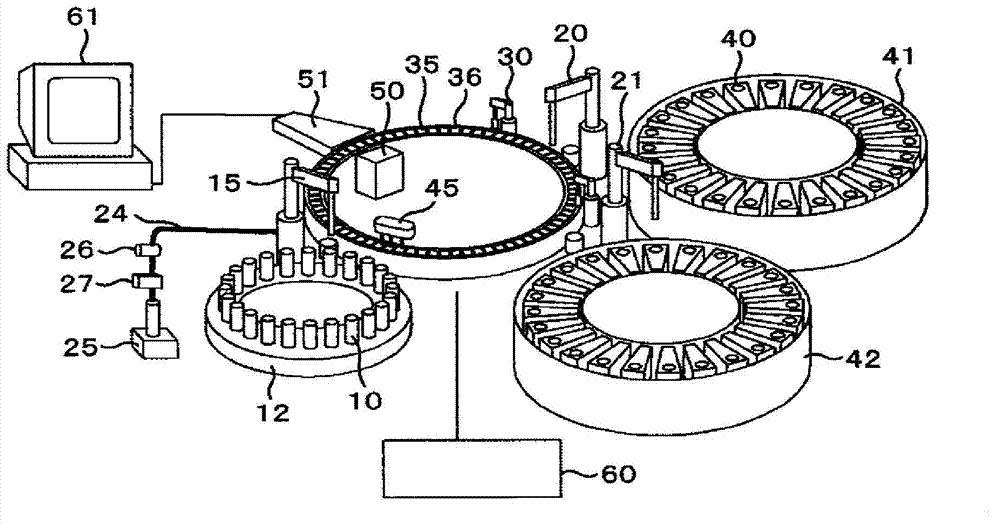

[0036] figure 1 , figure 2 An example of an automatic analyzer to which the present invention can be applied is shown.

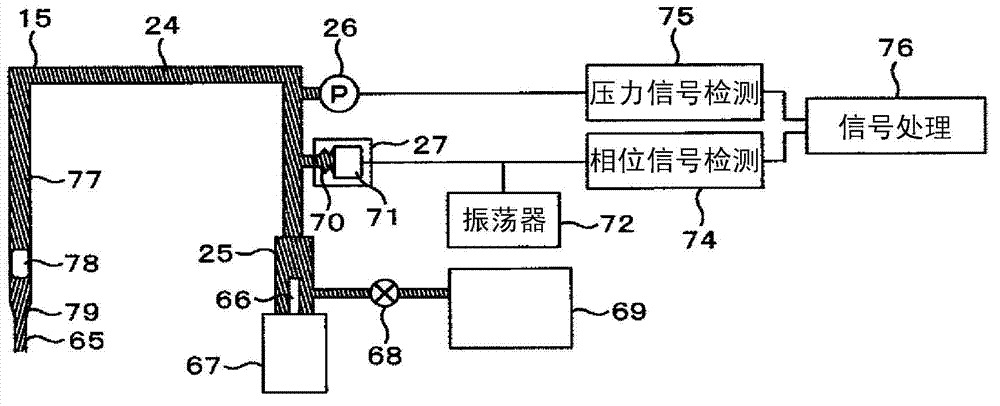

[0037] It consists of the following parts: a sample disc 12 capable of mounting a plurality of sample containers 10 for holding samples, a first reagent disc 41 and a second reagent disc 42 capable of mounting a plurality of reagent containers 40 for holding reagents, and a surrounding area. The reaction disk 36 on which a plurality of reaction containers 35 are arranged, the sample tube 15 for dispensing the sample aspirated from the sample container 10 into the reaction container 35, and the reagent aspirated from the reagent container 40 in the first reagent disk 41 to the reaction chamber. The first reagent tube 20 for dispensing the container 35, the second reagent tube 21 for dispensing the reagent suctioned from the reagent container 40 in the second reagent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com