Method for improving gold mine flotation and flotation concentrate cyaniding leaching recovery rate

A technology of flotation concentrate and recovery rate, which is applied in flotation, solid separation, etc., can solve the problems of lower grade and higher gold cost in concentrators, and achieve the effect of improving flotation recovery rate and making full use of it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

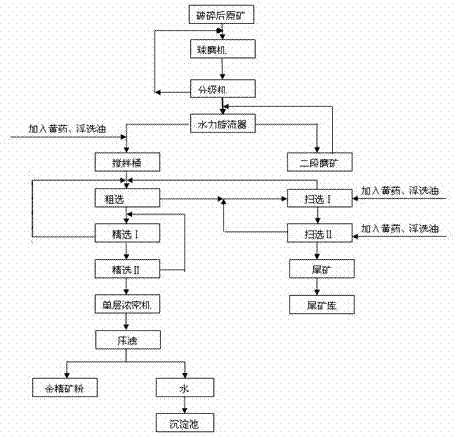

[0012] refer to Figure 1-Figure 2 , the gold ore flotation described in the method for improving gold ore flotation and flotation concentrate cyanidation leaching recovery rate of the present embodiment, the raw ore after the crushing is carried out two stages of ore grinding after ball mill grinding and classifier classification, after that The flotation operation adopts primary roughing, secondary beneficiation, and secondary sweeping to select the concentrate and discard the tailings. The concentrate is concentrated by a single-layer thickener and then filtered by a filter to obtain the final gold concentrate powder. When the ore is ground by ball mill, graded by classifier and roughed in three flotation operations, hot water is added, and the temperature of the hot water is 35-45 °C.

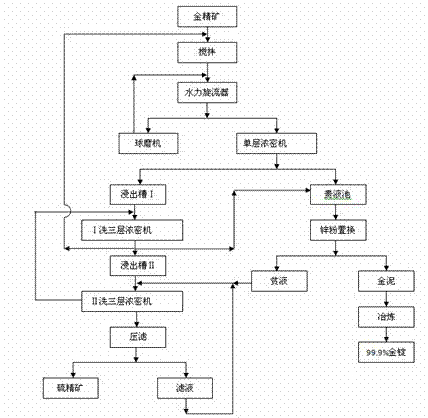

[0013] In the cyanidation leaching of the flotation concentrate, the final gold concentrate powder obtained by flotation is subjected to cyanidation leaching. After the gold concentrate pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com