Injection device of injection molding machine

An injection device and injection molding machine technology, applied in the field of injection devices, can solve the problems of reduced molding quality of plastic products, retained residual stress of products, assistance in process steps, etc., so as to reduce injection pressure loss, improve production efficiency and product quality, and ensure product quality. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

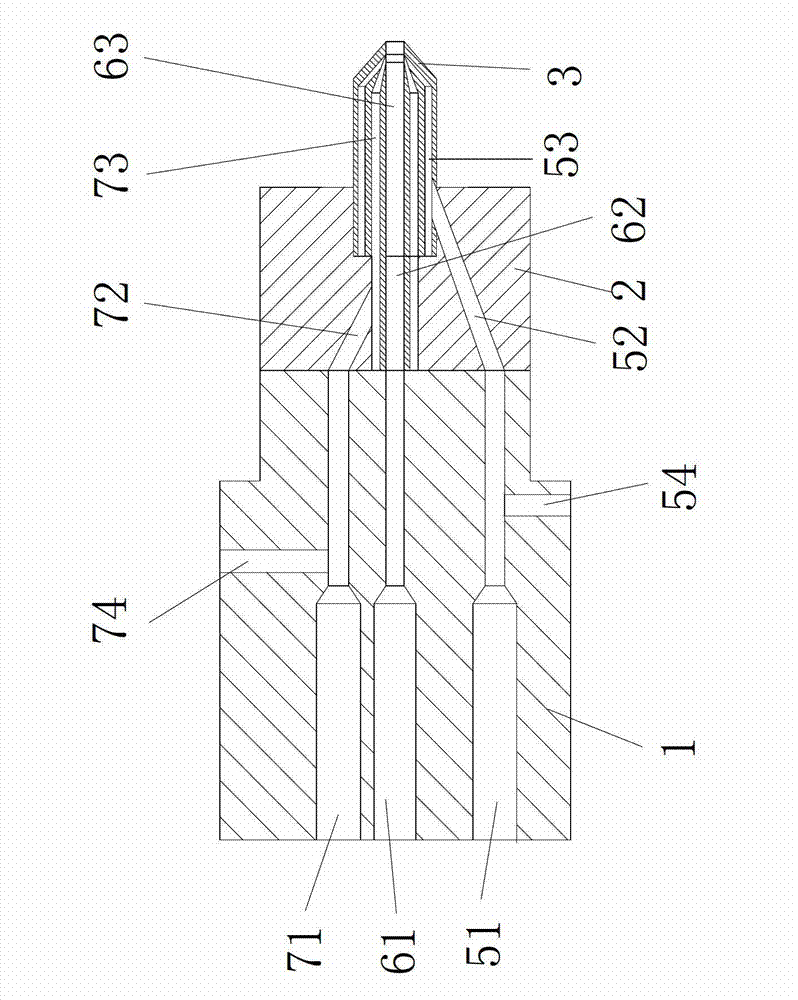

[0019] In the first embodiment of the present invention, please continue to refer to figure 1 Shown. A first barrel passage 61, a second barrel passage 71 and a third barrel passage 51 are penetrated inside the barrel body 1. A first connecting channel 62, a second connecting channel 72 and a third connecting channel 52 are provided inside the connecting body 2. A first nozzle passage 63, a second nozzle passage 73, and a third nozzle passage 53 are arranged inside the nozzle 3. The first injection channel includes a first cartridge channel 61 located in the cartridge body 1, a first connection channel 62 located in the connecting body 2, and a first nozzle channel 63 located in the nozzle 3. The second injection channel includes a second cartridge channel 71 located in the cartridge body 1, a second connection channel 72 located in the connecting body 2, and a second nozzle channel 73 located in the nozzle 3. The third injection passage includes a third barrel passage 51 lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap