Drive axle assembly with fixed structure

A drive axle assembly and fixed structure technology, applied in the direction of elastic couplings, couplings, control devices, etc., can solve the problems of low strength, affecting the bearing capacity of drive axles, poor stability, etc., achieve good results and improve load bearing Ability, strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

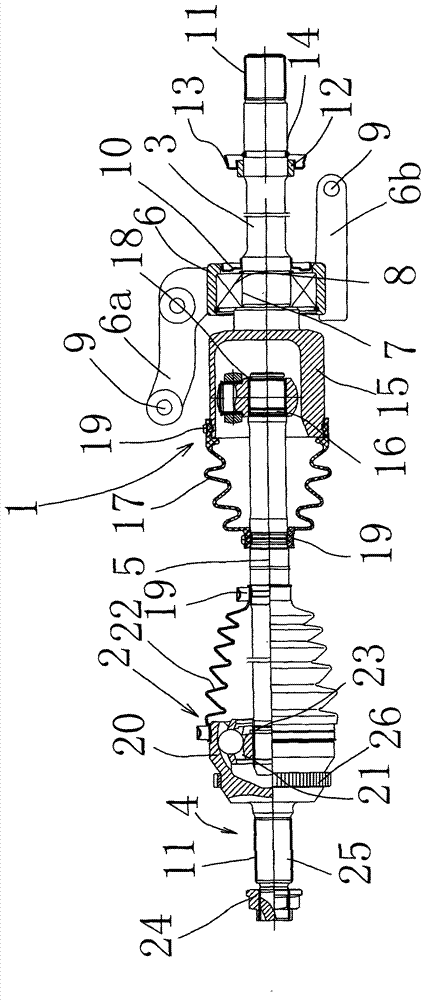

[0016] In the figure, the inner ball cage 1; the outer ball cage 2; the input shaft 3; the output shaft 4; the transmission shaft 5; the fixed connection frame 6; the first extension 6a; the second extension 6b; the accommodation hole 7; the bearing 8; Locking hole 9; dustproof ring 10; spline 11; pressure ring 12; retaining ring 13; rubber O-ring 14; 18; clamp 19; fixed end shell 20; outer cage assembly 21; fixed end dust cover 22; stop retaining ring 23; connecting nut 24; fixed end bell shell 25;

[0017] Such as figure 1 As shown, the drive axle assembly with a fixed structure includes an inner ball cage 1, an outer ball cage 2, an input shaft 3, an output shaft 4, and a transmission shaft 5. The inner ball cage 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com