Non-autoclaved prestressed high-strength centrifuge pipe pile and preparation method thereof

A prestressed, centrifugal tube technology, used in sheet pile walls, reinforcement molding, construction, etc., to protect the environment, reduce energy consumption and one-time investment, and improve vertical bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

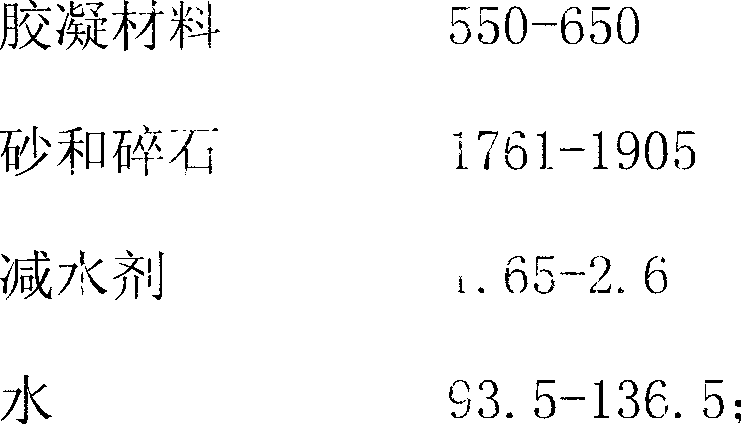

[0022] Preparation of pressure-free steamed prestressed high-strength centrifugal piles:

[0023] A. Put 445Kg / m 3 Cement, 70Kg / m 3 Microbeads, 35Kg / m 3 Silica fume, 720Kg / m 3 Sand, 1191Kg / m 3 Gravel, 1.9Kg / m 3 Water reducer, 104.5kg / m 3 Water, wherein the water-binder ratio is 0.19 mixed to make concrete;

[0024] B. After the above-mentioned concrete is distributed in the steel mold, and the mold is clamped and stretched, it is centrifugally formed on a centrifuge to make a prestressed concrete two-pipe pile. The centrifugal forming process is divided into four types: low speed, medium speed, medium high speed, and high speed. stage;

[0025] C. The prestressed concrete pipe pile after centrifugal forming should be cured by atmospheric pressure steam or water once, and the constant temperature should be controlled at 75°C-95°C; then it should be parked naturally for 7 days, and the concrete strength is 118.0MPa.

Embodiment 2

[0027] Preparation of pressure-free steamed prestressed high-strength centrifugal piles:

[0028] A. Put 460Kg / m 3 Portland cement with strength grade 42.5, 100Kg / m 3 Microbeads, 40Kg / m 3 Silica fume, 700kg / m 3 Sand, 1144Kg / m 3 Gravel, 2.1kg / m 3 Polycarboxylate superplasticizer, 102kg / m 3 Water, wherein the water-binder ratio is 0.17 mixed to make concrete;

[0029] B. Use the above-mentioned concrete in the steel mold for distribution, clamping and tensioning, and then centrifugally form it on a centrifuge to make prestressed concrete piles. The centrifugal forming process is divided into four types: low speed, medium speed, medium high speed, and high speed. stage,

[0030] C. The prestressed concrete pipe pile after centrifugal forming should be cured by atmospheric pressure steam or water once, and the constant temperature should be controlled at 75°C-95°C; then it should be parked naturally for 7 days, and the concrete strength is 118.8MPa.

Embodiment 3

[0032] Preparation of non-pressure steamed prestressed square high-strength centrifugal piles:

[0033] A. Put 520Kg / m 3 Cement, 65Kg / m 2 Microbeads, 65Kg / m 3 Silica fume, 640Kg / m 3 Sand, 1139kg / m 3 Gravel, 2.25kg / m 3 Water reducer, 117Kg / m 3 Water, wherein the water-binder ratio is 0.18 mixed to make concrete;

[0034] B, adopt above-mentioned concrete in steel formwork cloth, after clamping the mold and stretching, centrifugal forming on the centrifuge makes the prestressed concrete pipe pile, divides low speed, medium speed, medium high speed, high speed four stages in the described centrifugal forming process;

[0035] C. The prestressed concrete pipe pile after centrifugal forming should be cured by atmospheric pressure steam or water once, and the constant temperature should be controlled at 75°C-95°C; then it should be parked naturally for 7 days, and the concrete strength is 120.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com