Mold casting method for hollow axle steel of high-speed passenger train

A hollow axle and high-speed railway technology, which is applied in the field of die casting of steel for high-speed railway passenger car hollow axles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the amount of molten steel is 50t, the liquidus is 1500°C, and the mass percentage of the chemical composition of the molten steel is:

[0023] C 0.27; Si 0.35; Mn 0.75; P 0.005; S 0.001; Cr 1.11;

[0024] Ni 0.25; Mo 0.28; V 0.05; Al 0.015; Cu 0.13; Ti 0.003;

[0025] N 0.0045; H 0.00005; 00.0010; the rest are Fe and unavoidable impurities.

[0026] The steps of this embodiment are:

[0027] 1. The temperature of the ingot mold before casting is 53°C.

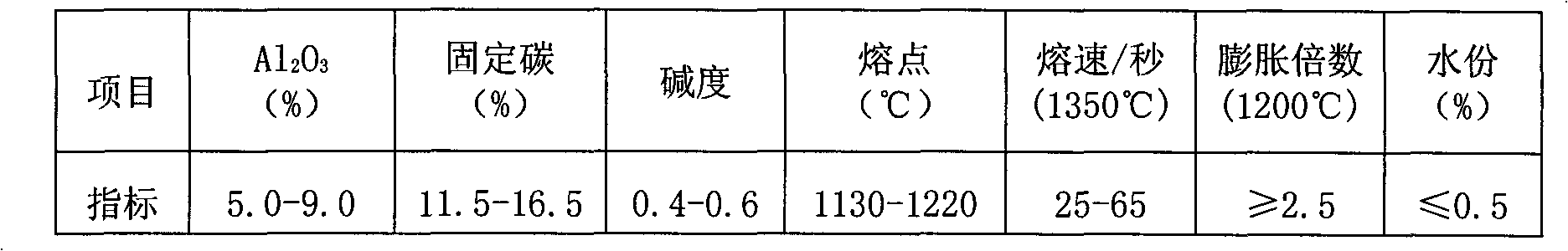

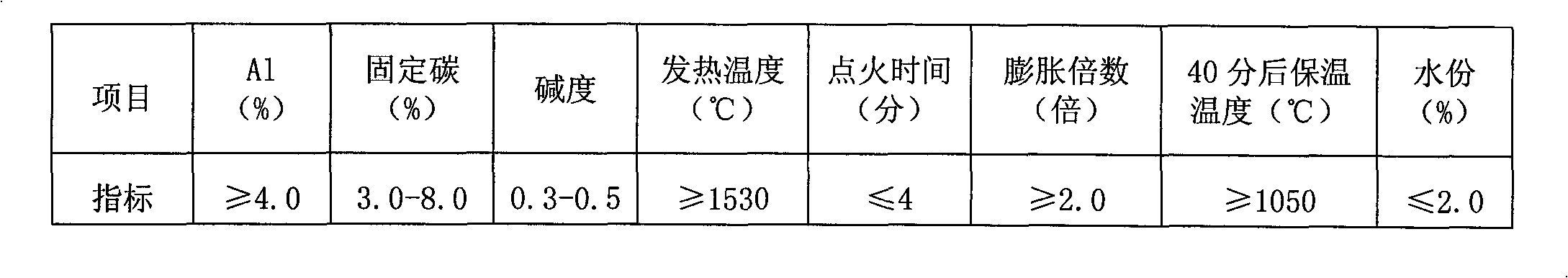

[0028] 2. Ingot type 5.8t, 2 disks, 4 ingot molds for each disk, the inside of the mold is cleaned before casting; the ingot mold is purged with argon, the tube is inserted into each disk, and the flow rate of 260L / min is used to blow argon gas 3.5 Minutes; 12Kg of mold flux is added to each tube.

[0029] 3. The temperature of the molten steel before pouring is 1535°C (the superheat of the molten steel is 35°C).

[0030] 4. Before pouring, the ladle is covered with a cover, and the cap is cover...

Embodiment 2

[0034] In this embodiment, the amount of molten steel is 160t, the liquidus is 1500°C, and the mass percent of the chemical composition of the molten steel is:

[0035] C 0.28; Si 0.36; Mn 0.75; P 0.003; S 0.001; Cr 1.11;

[0036] Ni 0.26; Mo 0.27; V 0.05; Al 0.017; Cu 0.13; Ti 0.003;

[0037] N 0.0047; H 0.00005; 00.0010; the rest are Fe and unavoidable impurities.

[0038] The steps of this embodiment are:

[0039] 1. The temperature of the ingot mold before casting is 60°C.

[0040] 2. Ingot type 8.4t, 3 trays, 6 ingot molds for each tray, and the inside of the mold is cleaned before casting; the ingot mold is purged with argon, and the tube is inserted into each tray and blown with argon at a flow rate of 360L / min 4 Minutes; 16Kg of mold powder is added to each tube.

[0041] 3. The temperature of molten steel is 1553 before pouring. (The degree of superheat of molten steel is 53°C).

[0042] 4. Before pouring, the ladle is covered with a cover, and the cap is covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com