Graphene-La2Ti2O7/zinc-aluminum-zirconium corrosion resisting coating for polycrystalline silicon ingot casting furnace

A technology for polysilicon ingot casting furnace and corrosion-resistant coating, which is applied in the preparation of high-temperature-resistant protective layer and high-temperature-resistant protective layer, and the field of corrosion-resistant coating, which can solve the problems that the strength and corrosion resistance need to be improved, and achieve the improvement of mechanical properties , prolong service life, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 prepares graphene powder

[0055] 1. Add 10g of graphite into the mixed solution of concentrated sulfuric acid and sodium nitrate, the mass ratio of concentrated sulfuric acid and sodium nitrate is 0.5:1, the mass ratio of concentrated sulfuric acid and graphite is 10:1, and the mixed solution is cooled to 0 ° C ~ 5 ℃, stir for 30min, continue to stir and slowly add potassium permanganate, the mass ratio of potassium permanganate to graphite is 2:1, raise the temperature to 10℃~15℃, continue to stir for 12h, and then introduce the mixed solution at a temperature of 30℃ In a water bath at ~40°C, slowly add 200ml of water after reacting for 30min, raise the temperature to 90°C~100°C and keep it for 35min, then add hydrogen peroxide and 100ml of water, the mass ratio of hydrogen peroxide and graphite is 0.5:1, stir for 2h and then use hydrochloric acid and Alternately wash with water for 4 times, filter after rinsing with water, dry the filter cake, grind and ...

Embodiment 2

[0059] 1. Take 25wt% zinc powder with a particle size of 100 mesh, 40wt% aluminum powder with a particle size of 100 mesh, and 40wt% zirconium powder with a particle size of 100 mesh, and mix them uniformly to obtain co-infiltration agent powder; take the prepared co-infiltration agent and carbon fiber heat insulation Put the layer into the vacuum infiltration furnace, and embed the carbon fiber insulation layer in the infiltration agent. The volume ratio of the infiltration agent to the workpiece is 1:1. Vacuum the vacuum furnace to a vacuum degree of less than 0.5kPa. The co-infiltration furnace is heated up to 350°C, and the vacuum furnace is rotated 3 times per minute. After 8 hours of heat preservation, the carbon fiber insulation layer is taken out, cleaned and dried in the sun.

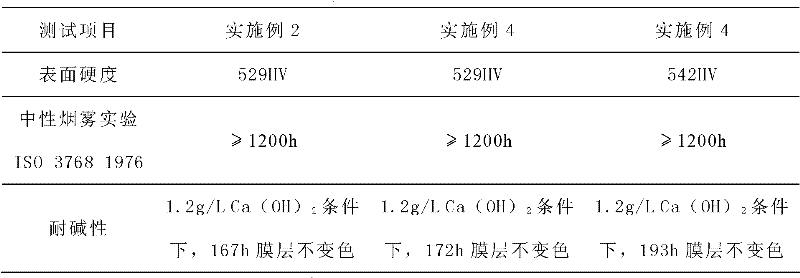

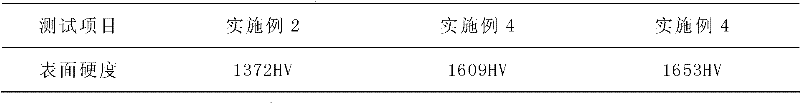

[0060] Samples were taken for testing, and an alloy anti-corrosion layer with a thickness of about 80 microns was formed on the surface of the carbon fiber heat insulation layer. The hardness a...

Embodiment 3

[0065]1. Take 35wt% zinc powder with a particle size of 300 mesh, 35wt% aluminum powder with a particle size of 300 mesh, and 30wt% zirconium powder with a particle size of 300 mesh, and mix them evenly to obtain co-infiltration agent powder; take the prepared co-infiltration agent and carbon fiber heat insulation Put the layer into the vacuum infiltration furnace, and embed the carbon fiber insulation layer in the infiltration agent. The volume ratio of the infiltration agent to the workpiece is 1:1. Vacuum the vacuum furnace to a vacuum degree of less than 0.5kPa. The co-infiltration furnace is heated up to 500°C, and the vacuum furnace is rotated 3 times per minute. After 8 hours of heat preservation, the carbon fiber insulation layer is taken out, cleaned and dried in the sun.

[0066] Samples were taken for testing, and an alloy anti-corrosion layer with a thickness of about 80 microns was formed on the surface of the carbon fiber heat insulation layer. The hardness and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com