A kind of home textile filler mixed with polyester fiber and lyocell fiber and preparation method thereof

The technology of polyester fiber and polyester staple fiber is applied in the field of home textile filler and its preparation, which can solve the problems of low elastic modulus and poor bulkiness, and achieve the effects of high elastic recovery rate, light weight and good heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The hollow polyester staple fibers and lyocell fibers that are 25% by weight: 75% are opened, mixed, and carded, and then air-sent and filled to obtain the filled product, and its bulkiness is measured to be 80cm 3 / g, the compression rate is 71%, the heat preservation rate is 92.25%, the elasticity rate is 91%, and the air permeability rate is 52.2%. It can be seen from the above data that the above-mentioned products are light, fluffy, good in air permeability, high in elastic recovery rate, good in warmth retention, and soft and comfortable to the touch.

Embodiment 2-5

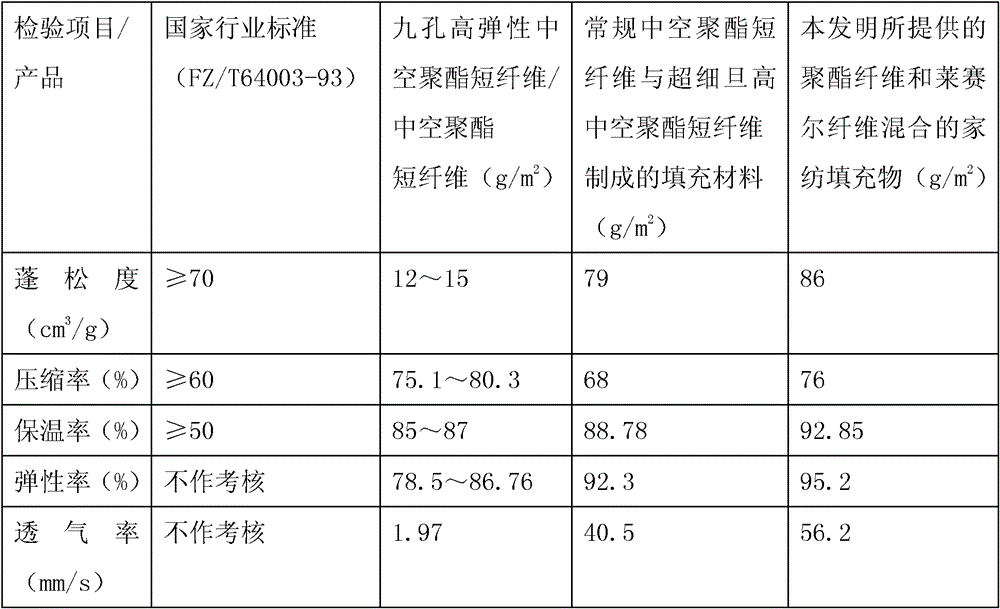

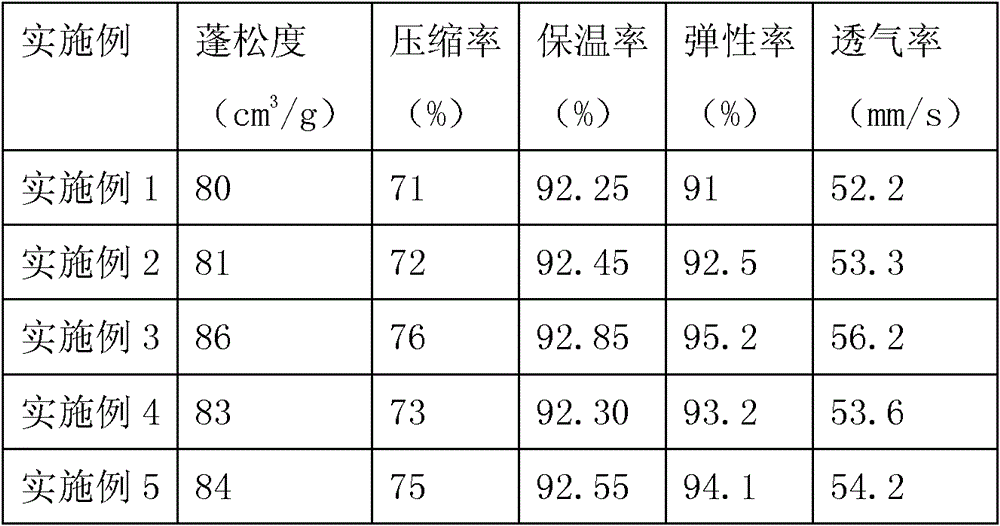

[0030] Method and technique are identical with embodiment 1, and the percentage by weight of hollow polyester staple fiber and lyocell fiber is shown in Table 2, and each technical index of the product that obtains after filling is shown in Table 3, from the data of Table 3 and As can be seen from the actual test results, each product in Examples 2 to 5 has the advantages of lightness, fluffiness, good air permeability, high elastic recovery rate, good warmth retention, and soft and comfortable hand feeling.

[0031] Table 2

[0032] Example

Hollow polyester staple fiber weight percentage (%)

Lyocell fiber weight percentage (%)

Example 1

25

75

Example 2

45

55

Example 3

50

50

Example 4

55

45

Example 5

75

25

[0033] table 3

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com