Single-cantilever supporting system for vertically-rotary movable bridge and installing method thereof

A technology of supporting system and single cantilever, applied in the direction of opening bridges, bridges, bridge construction, etc., can solve the problems of inability to eliminate installation errors, large initial stress, influence, etc., and achieve the effect of enhancing reliability and reducing additional stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments.

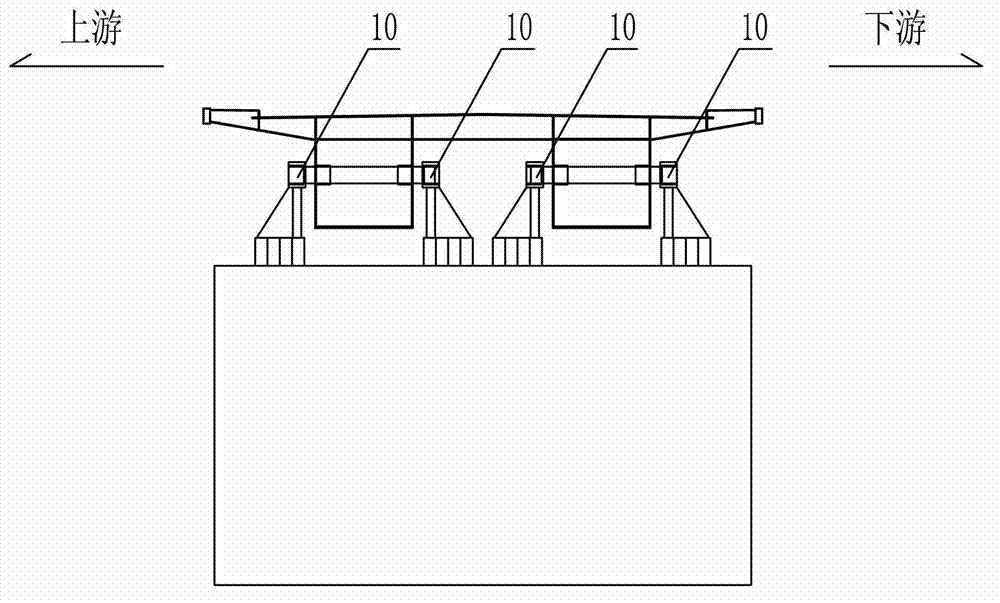

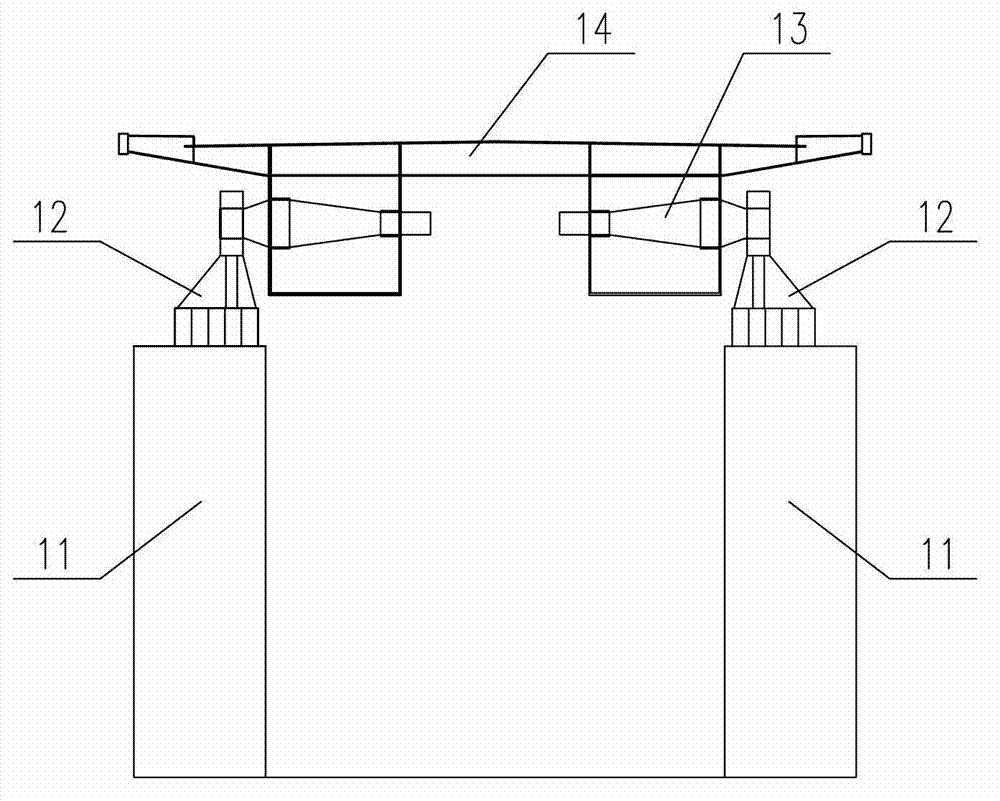

[0019] Such as figure 2 As shown, a single cantilever support system of a vertically rotating open bridge of the present invention includes four sets of support devices, and the four sets of support devices are symmetrically arranged on both sides of No. 0 intersection 14 of the main bridge of the open bridge according to two sets of each bank.

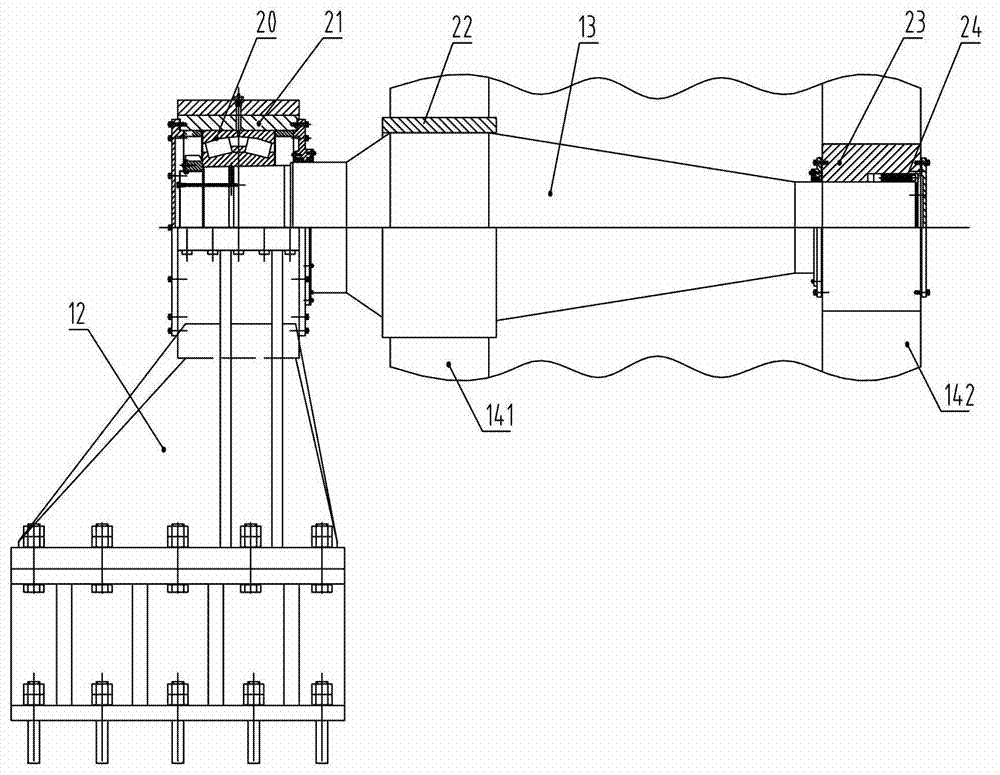

[0020] Such as image 3 As shown, the supporting device includes a base 11, a bearing seat 12, a bearing 20 and a pivot 13, one end of the pivot 13 is connected with the bearing seat 12 through a bearing 20, and the bearing 20 adopts a spherical roller bearing, and the The inner ring of the spherical roller bearing is fixedly connected with the pivot shaft 13, and a bearing sleeve A21 is provided between the outer ring of the spherical roller bearing and the bearing housing 12, and the pivot shaft 13 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com