Simple hydraulic pipe clamp pile splicing operation platform

A technology for operating platforms and hydraulic pipes, applied in the field of marine engineering, can solve problems such as troublesome welding and cutting, and achieve the effects of quick installation, safe and reliable connection, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

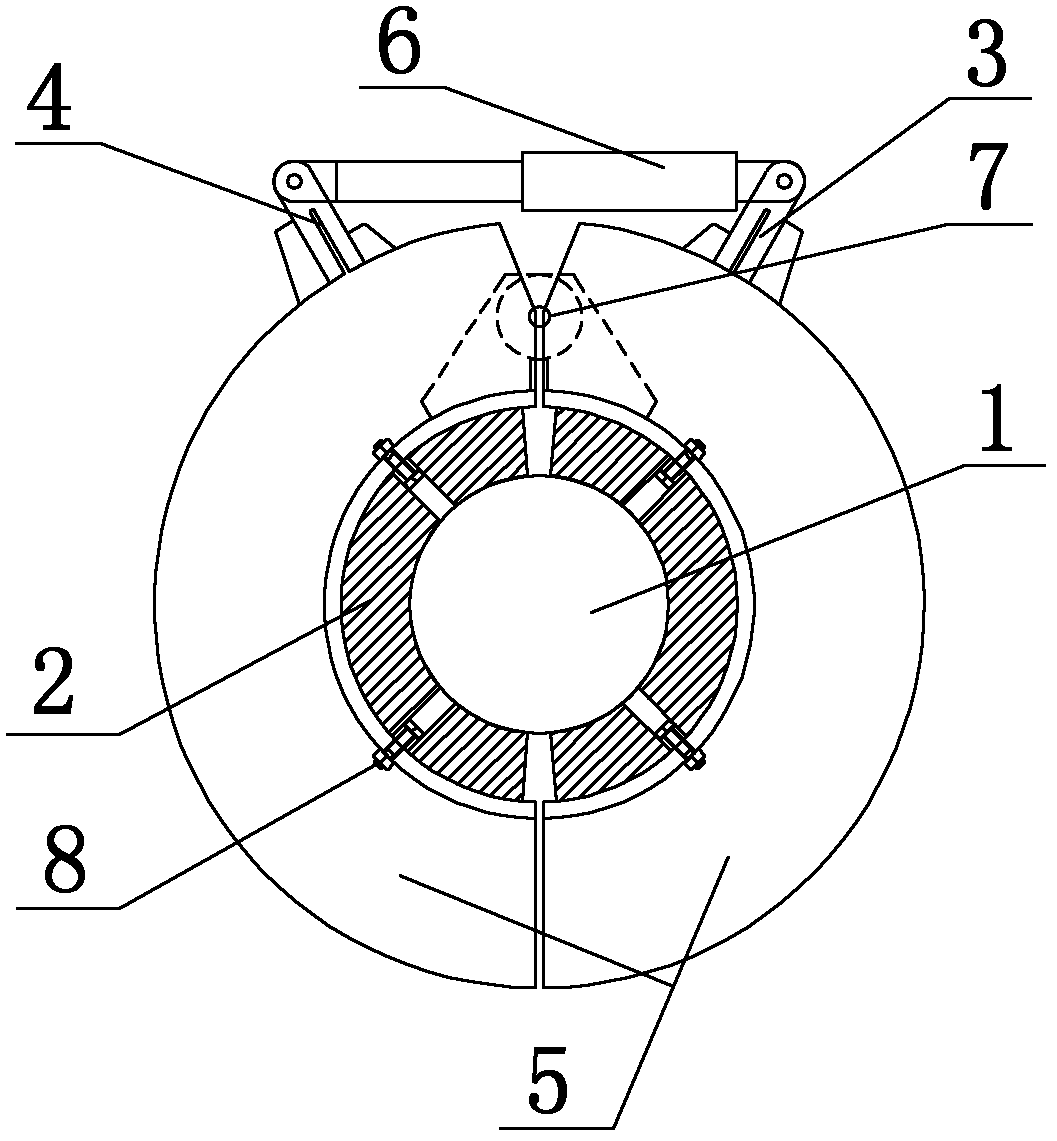

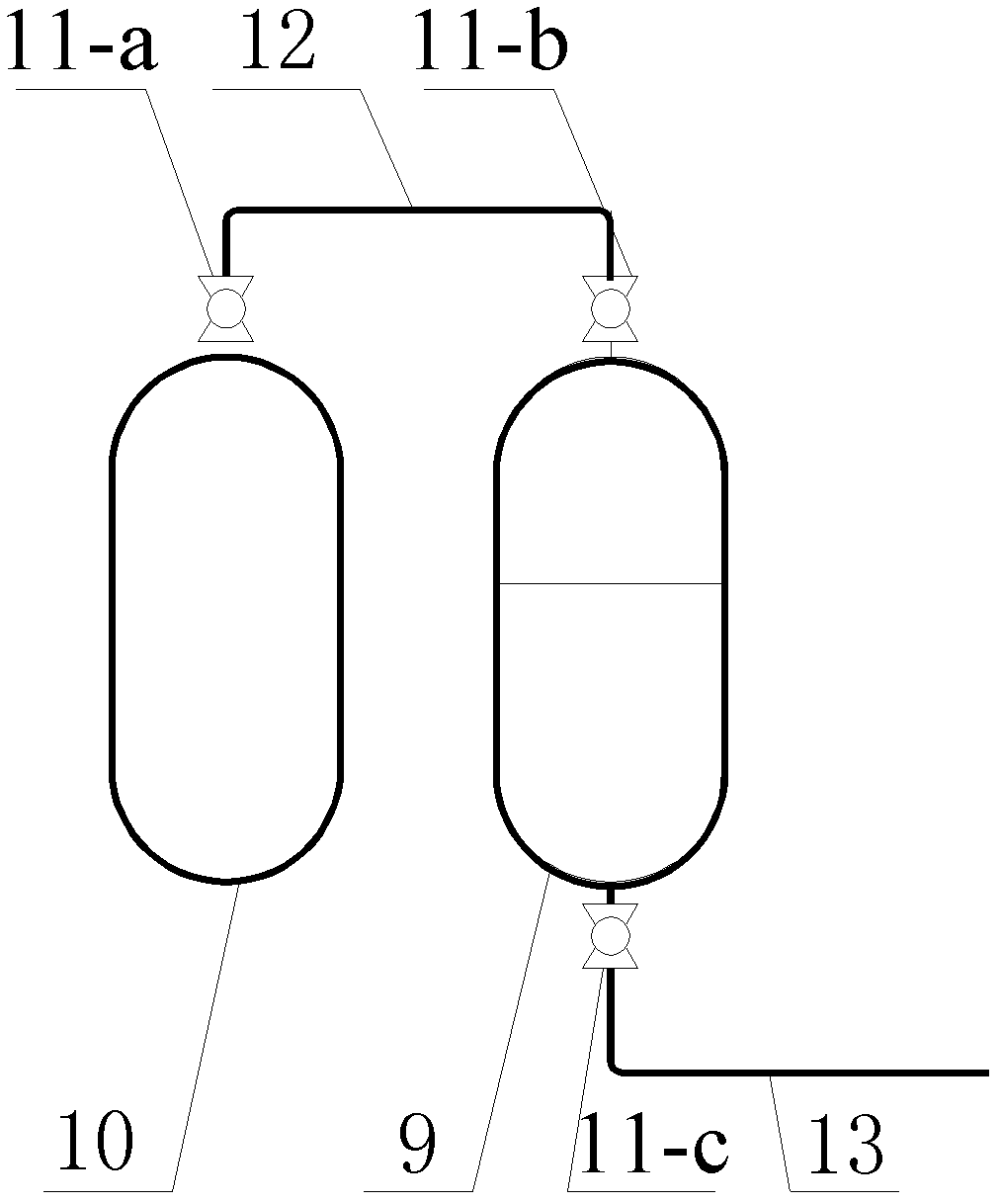

[0014] Such as figure 1 As shown, the hydraulic pipe clip is a component used to mechanically connect and fasten the pile connecting operation platform and the pile head. It is mainly composed of two clips 5 and two hydraulic cylinders 6, and the two clips 5 are connected by a pin shaft 7 The main structure of the hydraulic pipe clip is formed as a whole, and the two clips can be opened and closed arbitrarily with the pin shaft as the central axis. The two hydraulic cylinders are respectively placed at the upper and lower ends of the hydraulic pipe clamp, and the cylinder body is hinged with the dowel 1 3 on one of the clamps; the piston rod is hinged with the dowel 2 4 on the other clamp. The diameter-reducing pads 2 are two semi-circular steel blocks lined in the two clamps 5 of the hydraulic pipe clamp respectively, and are fixed together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com