Novel self-installing four-cylindrical-foundation two-upright wellhead platform

A self-installation and column technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of weak anti-tilting ability, small chassis area, and uneven force on the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

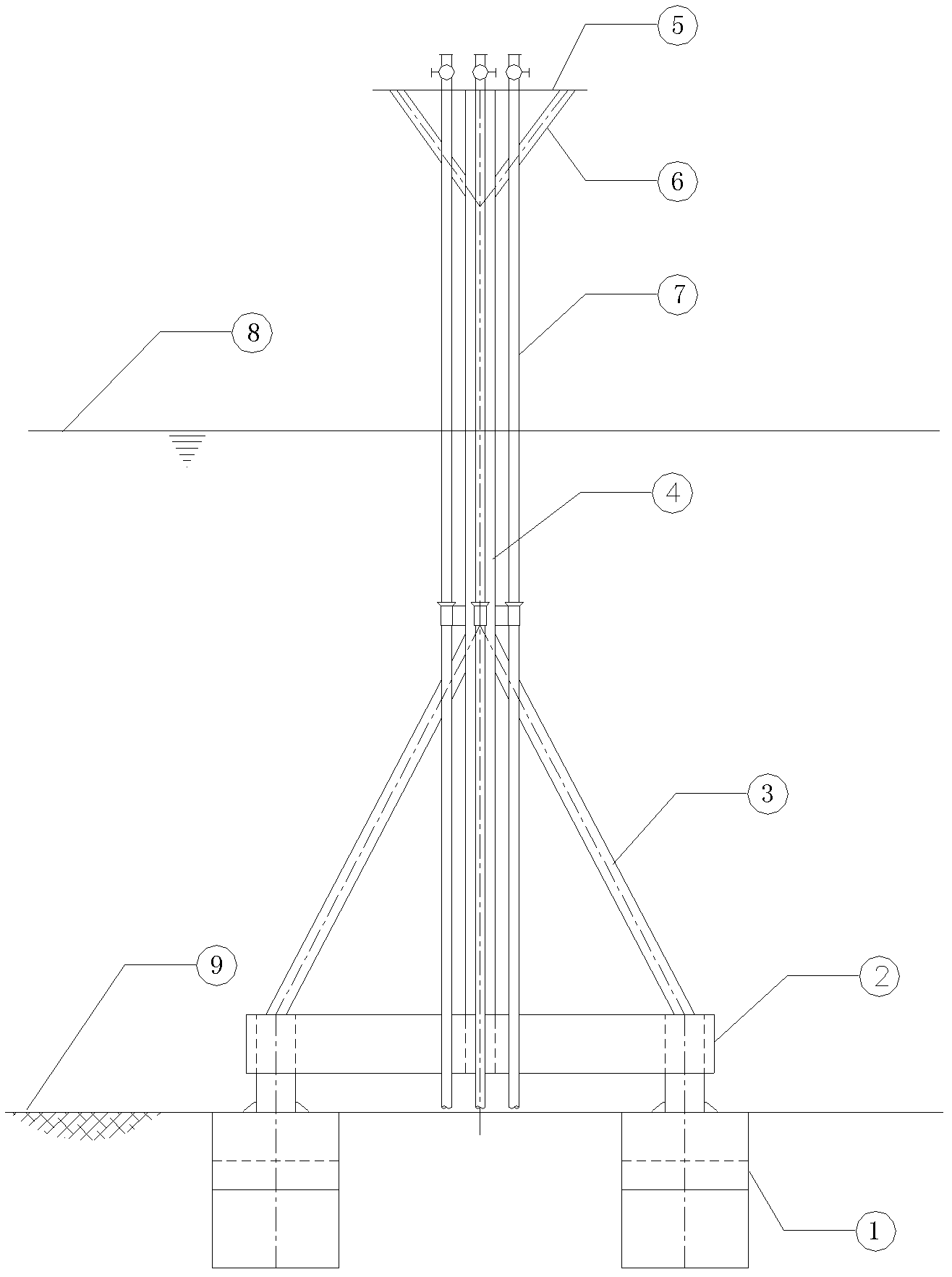

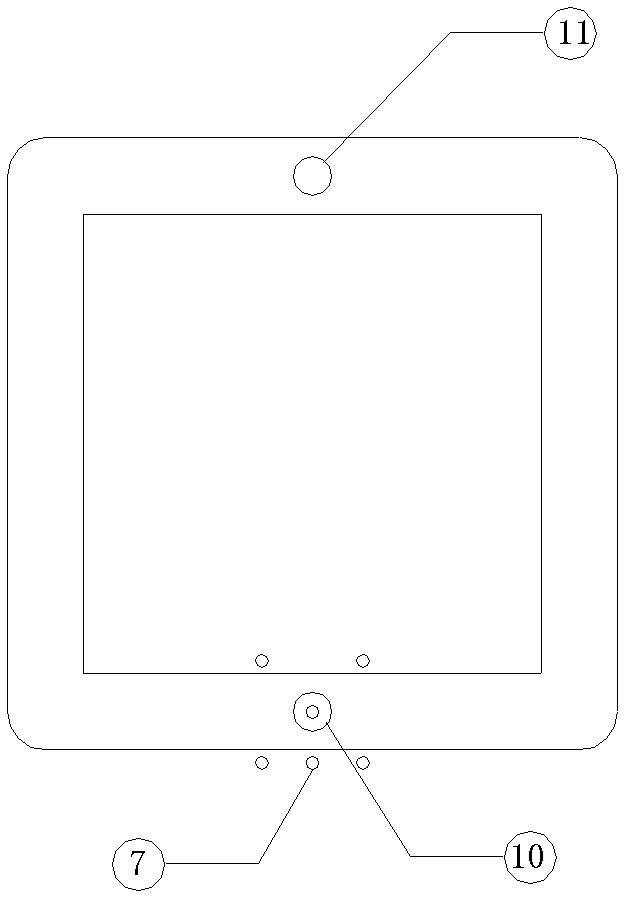

[0012] The self-installed four-tube foundation and two-column wellhead platform consists of four rectangularly arranged cylindrical foundations (1), a rectangular top frame (2) composed of box girders, a diagonal bracing system composed of triangular frames (3), It consists of two uprights (4) standing on the midpoint of the two-span box girders of the tube roof frame, a deck structure (5) supported by the uprights and supports (6), and a water-resisting casing (7) fixed by the uprights . During the prefabrication of this platform, the two columns (4) are divided into upper and lower sections by the fulcrum of the diagonal brace, and the lower column is constructed together with the diagonal brace system (3), the tube top frame (2), and the tube foundation (1). become the lower structure; the upper column, the deck support (6) and the deck structure (5) are integrated into a deck block; the lower structure has self-floating and self-sinking capabilities, and can realize self-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com