Support method of weak and broken surrounding rock tunnel

A technology for crushing surrounding rocks and tunnels, which is used in the support of large-deformed tunnels with crushed rocks, the support of tunnels with weak and broken surrounding rocks, and the fields of deeply buried soft rocks. progress and other issues, to achieve the effect of guaranteed construction quality, outstanding economy, and improved overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

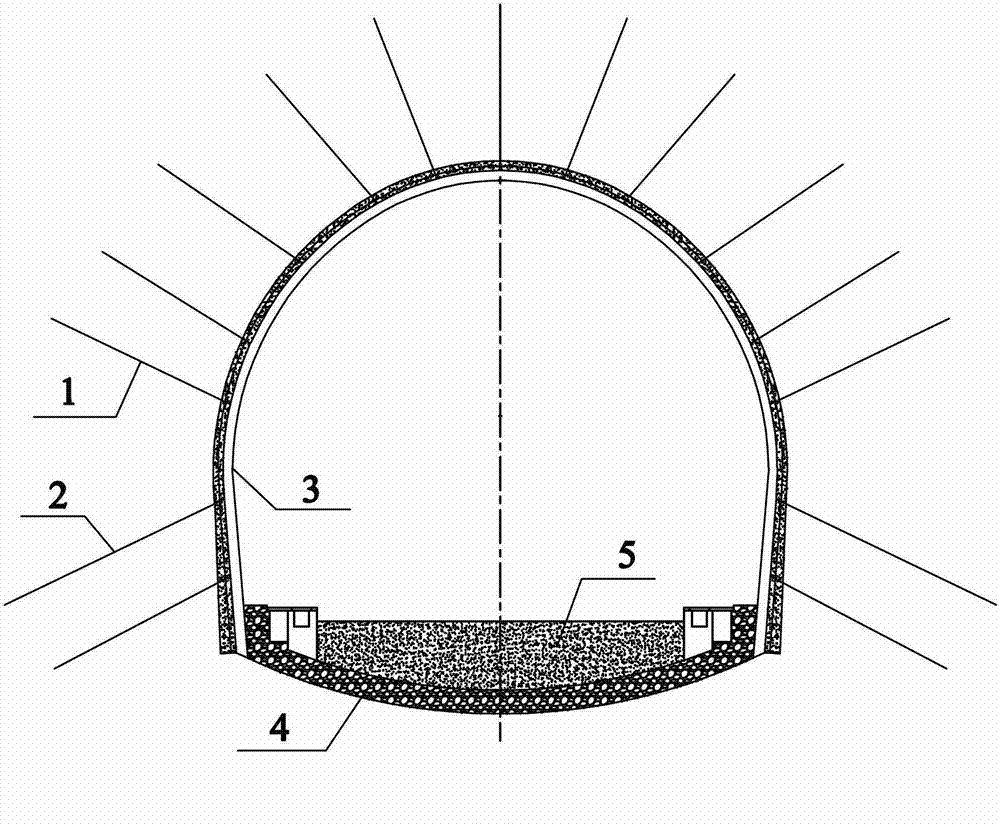

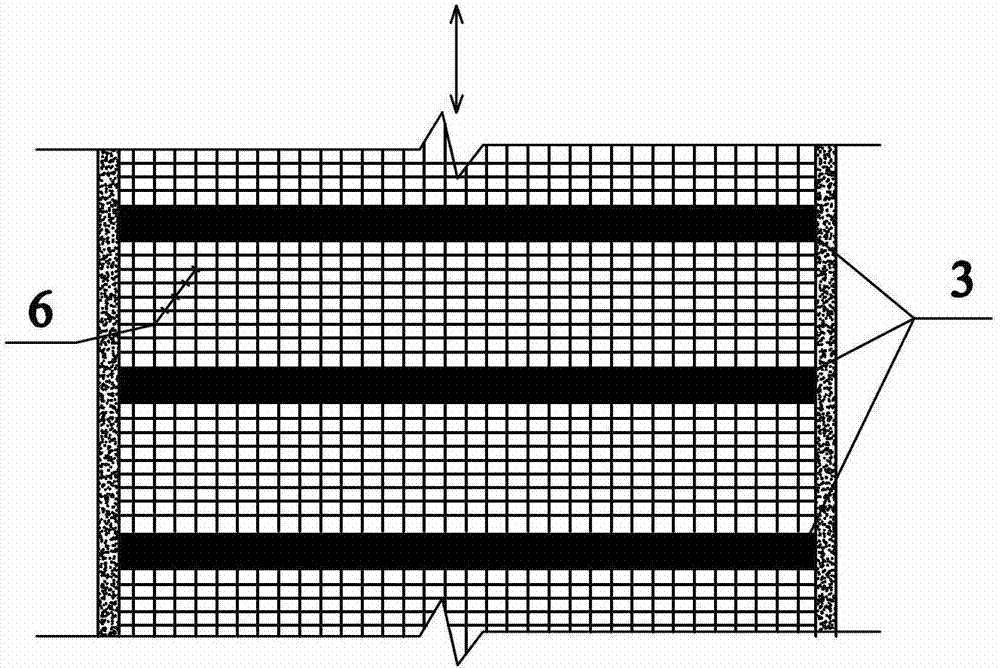

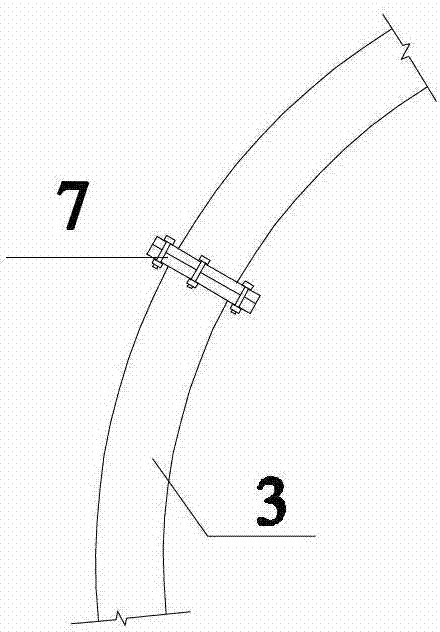

[0028] Such as figure 1 As shown, after the tunnel is excavated, the concrete is initially sprayed, and after the initial setting, the anchor rod 1 and the lock foot grouting conduit 2 are drilled to protect the surface of the tunnel and the side wall lock feet, and then the steel pipe restrained concrete support 3 is erected; The foot grouting conduit 2 adopts a small grouting conduit, and injects cement slurry or cement slurry-water glass double liquid into the anchor hole and the small grouting conduit; Pressure pocket protection. When this kind of support is erected, an empty steel pipe is first erected, then a grouting hole is opened at the bottom of the empty steel pipe, and a grouting hole is opened at the top of the empty steel pipe. The process of pumping concrete in the steel pipe is carried out after the single steel pipe support is erected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com