High-temperature bearing and seal assembly thereof

A technology of sealing components and high temperature resistance, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large space occupation, large size of parts, and large number of parts, so as to reduce the size and number of parts, reduce the Sealability, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

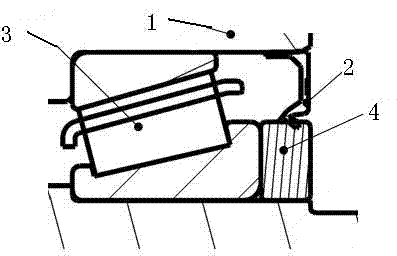

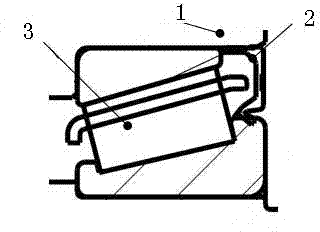

[0013] In order to further understand the high temperature resistant bearing and its sealing assembly, further description will be made in conjunction with the accompanying drawings.

[0014] High temperature resistant bearing and its sealing assembly, which includes: housing 1, shaft rubber body, dust-proof bearing 3 and sealing ring 2, dust-proof bearing 3 is installed between the housing 1 and the shaft rubber body, housing 1 and the shaft rubber The body is directly sealed as a whole. The top of the dustproof bearing 3 is provided with a sealing ring 2. The sealing ring 2 matches the outer diameter of the inner ring of the bearing. The sealing washer 4 of the current standard structure is removed. Diameter fit to achieve sealing, reduce the size and number of parts, that is, to achieve the role of high temperature resistant sealing, and reduce the volume and weight of the bearing.

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com