Heat radiation device

A heat dissipation device and heat sink technology, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problem that the heat dissipation area is not maximized, achieve long service life, and expand the heat dissipation area , High heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

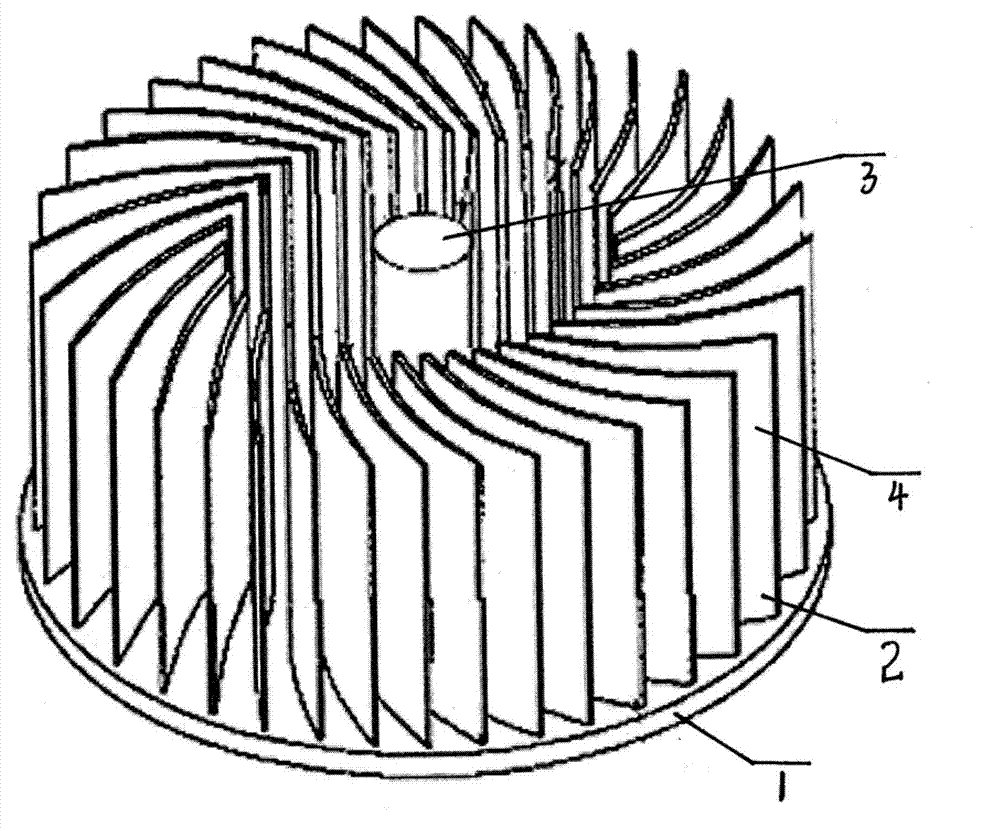

[0015] Such as figure 1 As stated, a heat dissipation device of the present invention includes an LED (not shown in the figure), a copper-aluminum substrate for carrying and installing the LED, and a heat sink arranged under the copper-aluminum substrate, (shown in the figure as an upside-down state of the heat dissipation device ) The heat sink includes an annular base and an axis column arranged in the base, the top surface of the base extends upwards to form a number of heat dissipation fins, the heat dissipation fins are in a streamlined arc shape, and the space between the heat dissipation fins A gap is formed.

[0016] The heat dissipation device of the present invention also includes a liquid storage tank and an electric pump. The axial column is a hollow cylinder, and the interior of the axial column is divided into a liquid inlet chamber and a liquid outlet chamber, wherein the liquid inlet chamber is connected to the liquid storage tank through the liquid inlet pipe....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com