Method and device for production and detection of collimator

A technology of collimator and equipment, which is applied to instruments, optical devices, measuring devices, etc., can solve the problems of inaccuracy determination and low measurement, and achieve the effect of reliable measurement value and measurement inaccuracy avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

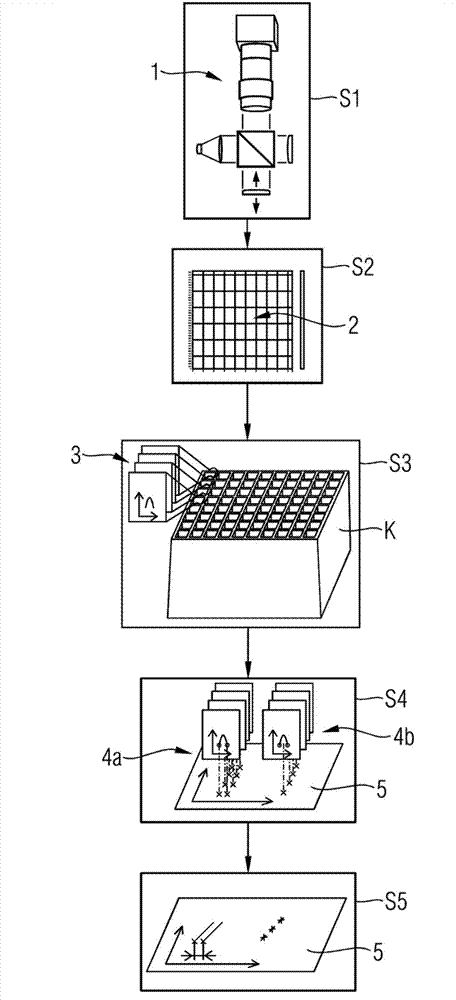

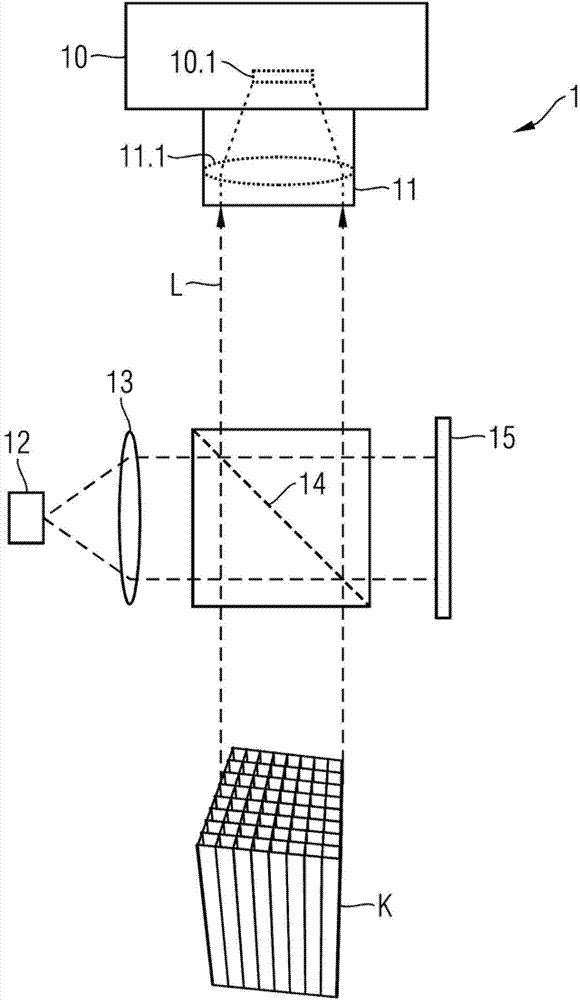

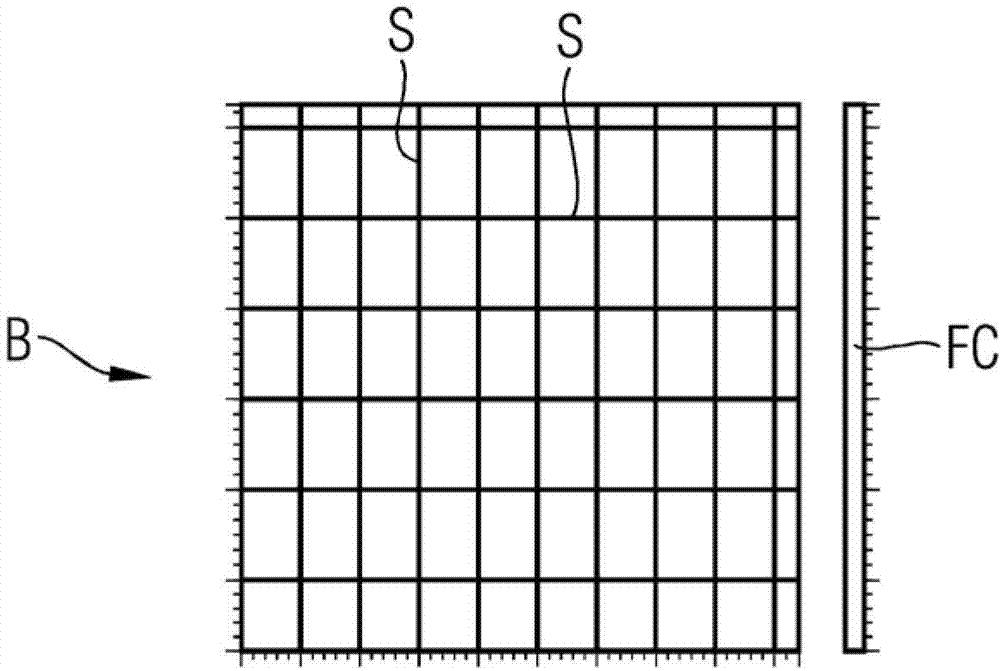

[0036] figure 1 A schematic diagram of a method sequence according to the invention with method steps S1 to S5 is shown. This method is carried out in order to check the dimensional accuracy of the edges of the collimator K. The collimator K is a two-dimensional scattering shielding grid with a plurality of rectangular mutually arranged tubes, the walls of which form a grid sheet with edges and grid holes. The collimator K has an entry plane and an exit plane for the radiation to be attenuated, the entry plane being smaller than the exit plane. In the configuration shown here, the entry plane of the collimator K is checked.

[0037] To do this, perform the steps described below. In a first step S1 , a three-dimensional measurement data record 2 of the collimator K is generated by the white light interferometer 1 and output in a step S2 . The measurement data set 2 contains in particular three-dimensional height information about the slices of the collimator. In a method ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com