Test element analysis system

A technology for testing components and analysis systems, applied in the fields of analyzing materials, analyzing materials by electromagnetic means, measuring devices, etc., can solve the problems of complex and expensive ruthenium dioxide, expensive and uneconomical ruthenium dioxide contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

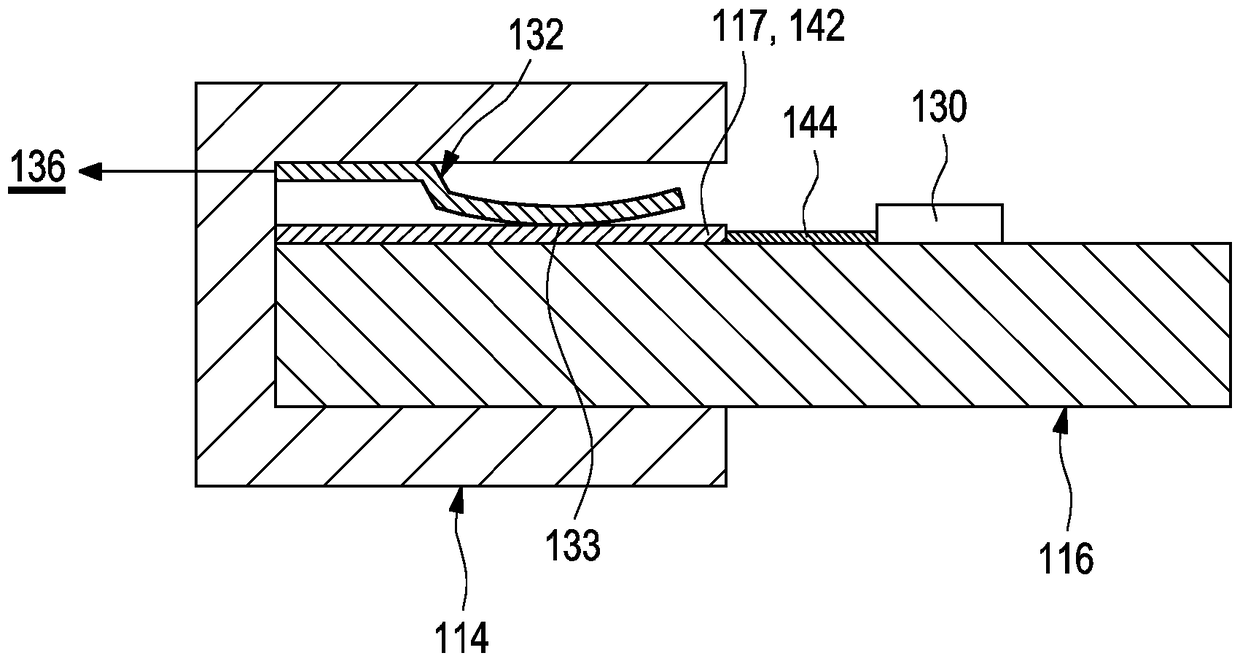

[0072] figure 1 A test element analysis system 110 including an evaluation device 112 is shown. The evaluation device 112 has a test element holder 114 for positioning a test element 116 containing a sample 118 . The test element holder 114 can be configured to position the test element 116 in figure 1 in the measurement position shown in . The test element 116 can be fixed in the measuring position by suitable means, for example by a spring element 120 . To carry out the measurement, a sample liquid can be brought into the measurement zone 122 of the test element 116 . In the illustrated embodiment, this is accomplished by applying a liquid droplet to a sample application zone 124 provided at the end of the test element 116 and transporting it from that location to the measurement zone via a transport zone 126 (eg capillary channel). 122 to happen. A reagent layer 128 may be located in the measurement zone 122, which reagent layer 128 may be dissolved by the sample liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com