Measuring device for two-phase flow split-phase flow in steady state

A measurement device and phase flow technology, applied in the direction of volume flow measurement device, measurement device, liquid/fluid solid measurement, etc. problems, to achieve the effect of increasing the repeated service life, simplifying the processing technology, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

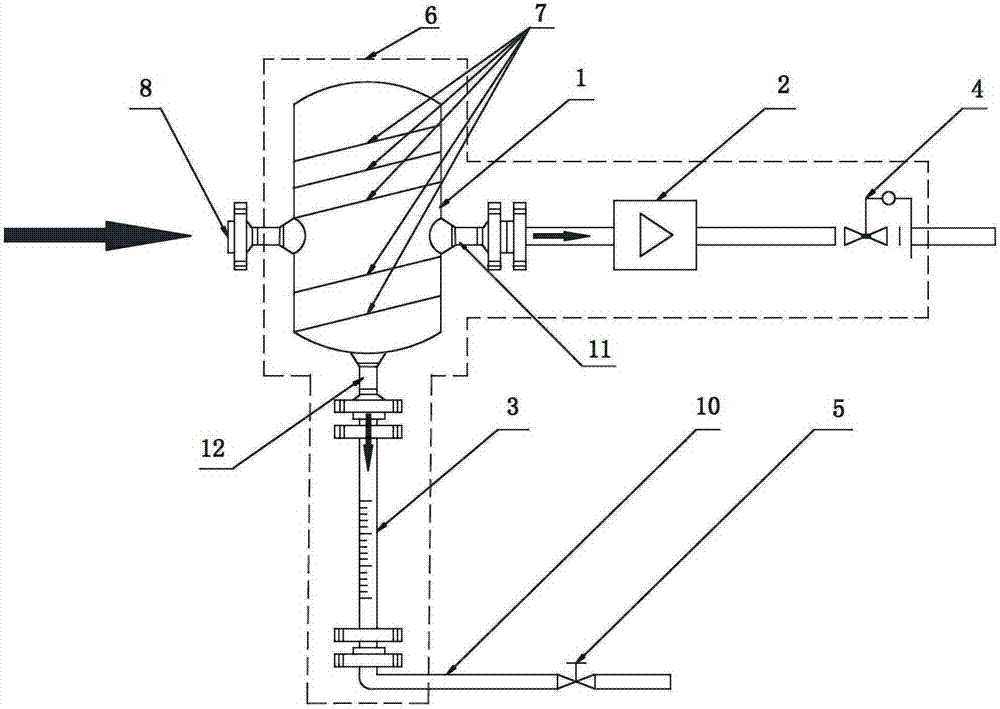

[0032] like figure 1 As shown, the device for measuring the flow rate of the two-phase flow in the steady state of the present invention mainly includes: a steam-water separator 1, a gas flow meter 2, a quartz glass tube with scale 3, a pressure reducing valve 4 and a shut-off valve 5.

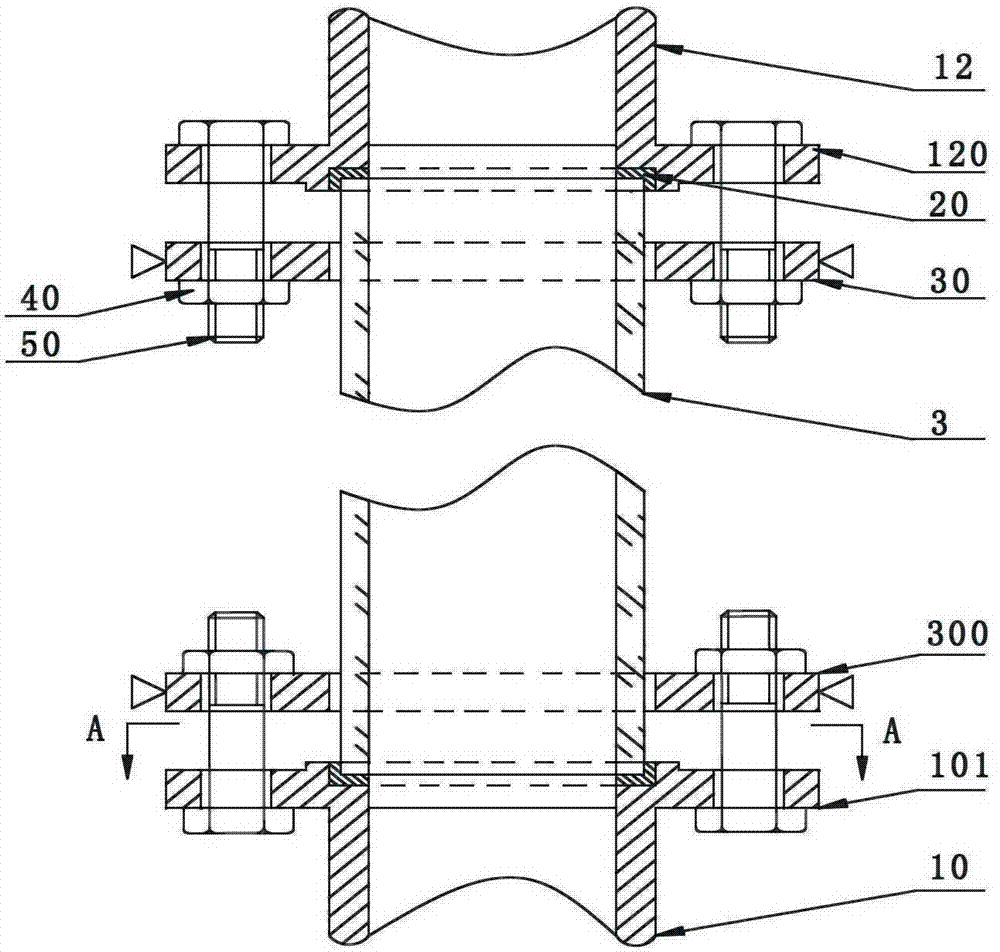

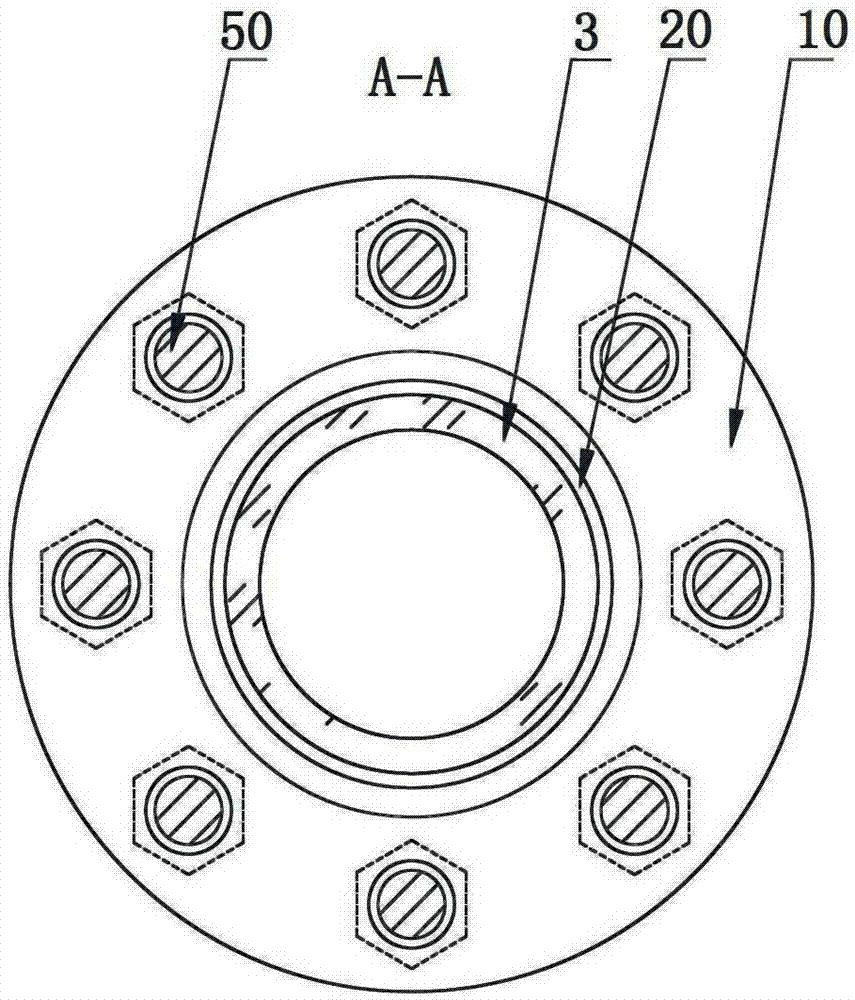

[0033] The side wall of the steam-water separator 1 is horizontally provided with a two-phase flow inlet 8 and a first outlet, and the bottom wall of the steam-water separator 1 is vertically provided with a second outlet. The vertically arranged second outlet is the liquid outlet after the separation of the two-phase flow, and the horizontally arranged first outlet is the gas / vapour outlet, which is connected with a metal pipe 11 . The second outlet is connected with a first metal tube 12, the first metal tube 12 is sealingly connected with the quartz glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com