Torsion calibration device and method for measurement beam used for ship model wave load test

A wave load and calibration device technology, which is applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

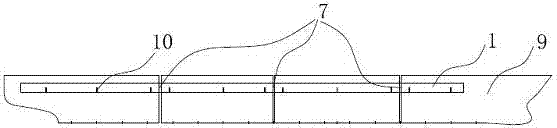

[0025] Before calibrating the strain-bending moment coefficients of each measurement section 7 of the measurement beam 1, the position of each measurement section 7 of the measurement beam 1 must be accurately located according to the position of the sectioned measurement section of the sectioned ship model 9, that is, the measurement The measurement profile 7 of beam 1 corresponds to the segmented measurement profile of segmented ship model 9, see figure 1 , figure 1 It is a schematic diagram of the assembly of the segmented ship model 9 and the measuring beam 1. In the figure, the ship model 9 is divided into 4 sections. The positions of each measurement section 7 of the sectioned ship model 9 correspond to each other in one-to-one correspondence.

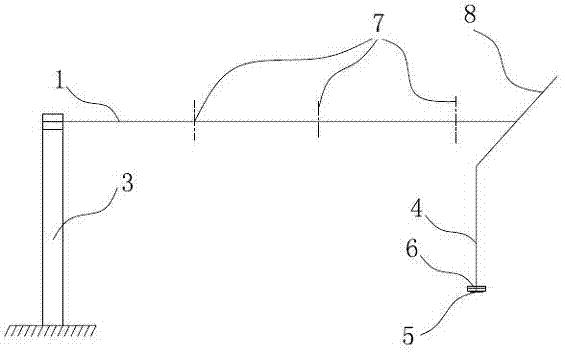

[0026] See figure 2 , the torque calibration device of the measuring beam for the ship model wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com