System capable of automatically compensating and focusing in process of automatic scanning and method and application thereof

An automatic compensation and automatic scanning technology, applied in microscopes, optics, instruments, etc., can solve problems such as unsatisfactory actual results and affect image clarity, and achieve the effect of not easy to slide down, light weight, and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

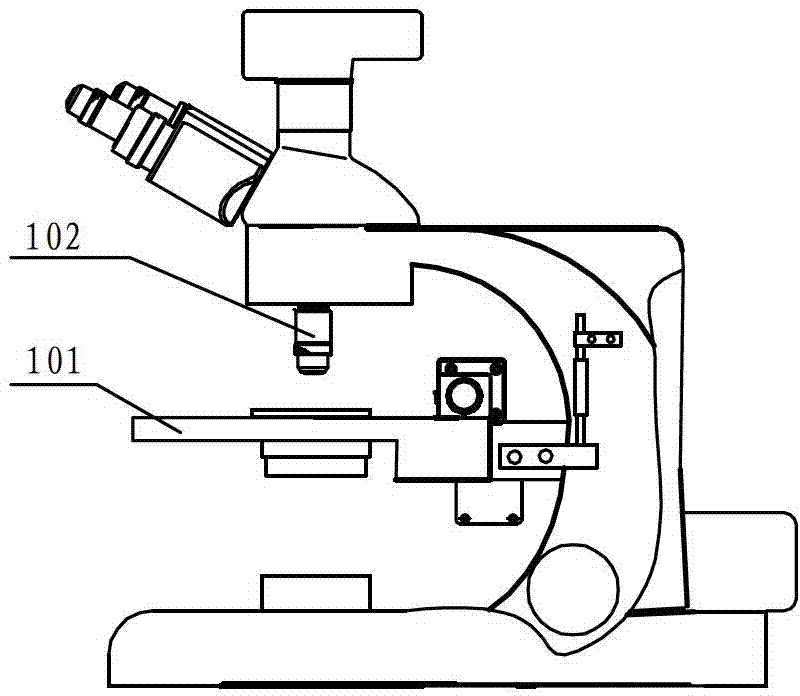

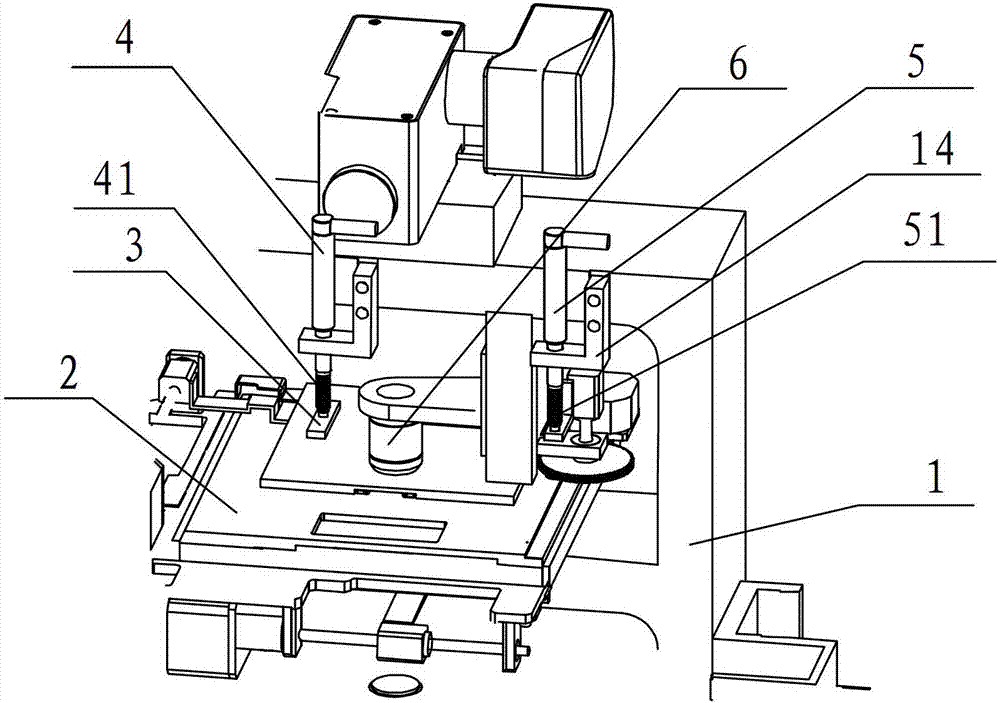

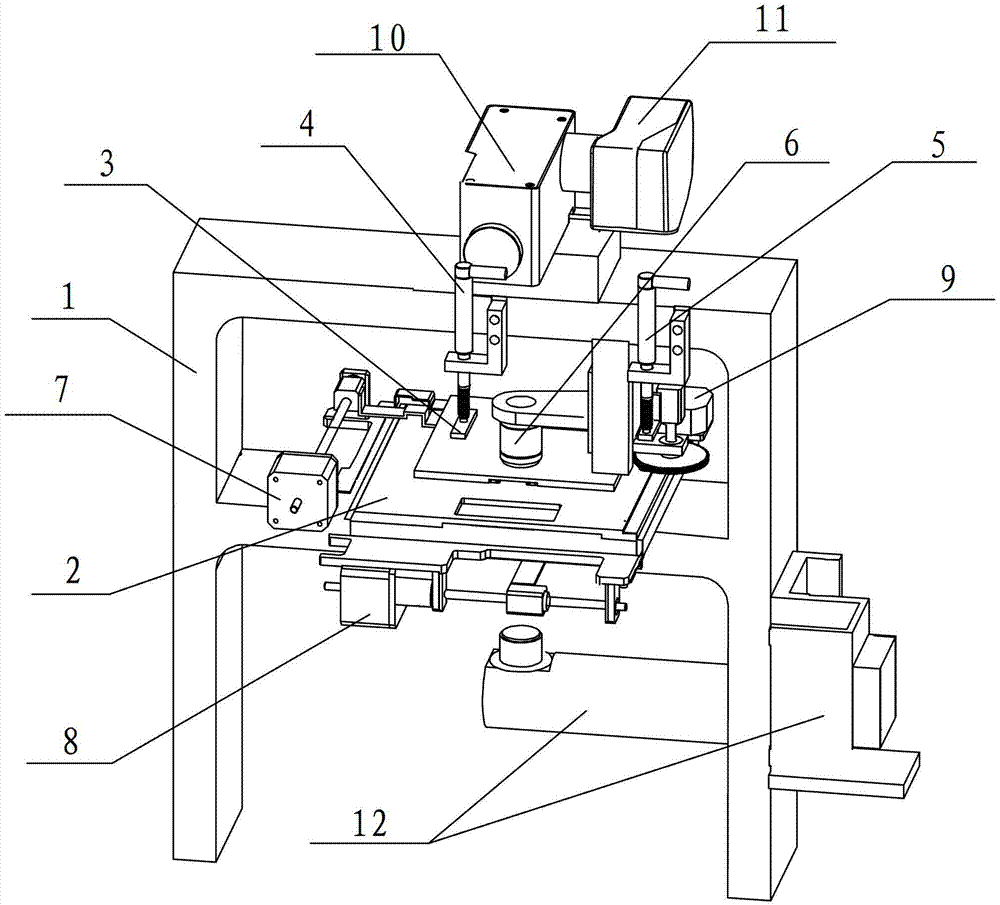

[0051] Such as image 3 , Figure 4 , Figure 5 A microscope based on a system for automatically compensating focus during automatic scanning is shown, including: a frame 1, an objective lens, a motor-driven stage, a motor-driven focusing (Z-axis) mechanism, an imaging optical system 10, Digital camera 11, light source lighting system 12.

[0052] The frame 1 is a gantry structure, and the object stage is fixed on the gantry frame. The object stage can move in the X and Y directions, but remains stationary in the Z direction, and is always fixed on the gantry frame. The gantry has enough rigidity to support the four corners of the stage to ensure that the change of the center of gravity of the stage caused by the movement of the stage in the X and Y directions will not affect the Z direction.

[0053] The stage is driven by motors, the first motor 7 drives the stage to move in the X direction, and the second motor 8 drives the stage to move in the Y direction.

[0054] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com