Control method of tobacco rolling and packing workshop production equipment

A technology of production equipment and control method, which is applied in the control field of tobacco rolling and packaging workshops, can solve problems such as complex production organization and material flow, long time for brand change, and difficult control, so as to achieve lean and visualization and avoid mistakes Card risk, the effect of improving coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

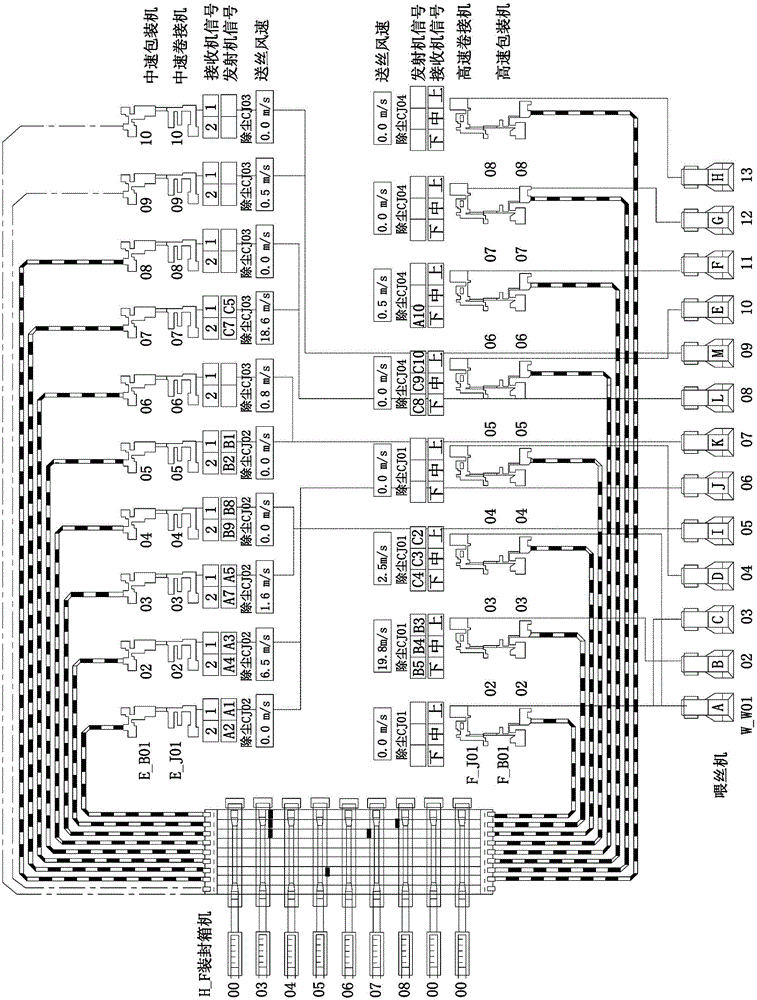

[0014] The control method of the production equipment in the tobacco wrapping workshop of the present invention first performs data interaction with the MES through the factory-level network, WebService and XML, receives the production work order issued by the MES in real time, and feeds back the production information and equipment information to the MES. The system then controls all the production equipment in the workshop through the industrial Ethernet network, and receives the equipment status information fed back by each production equipment.

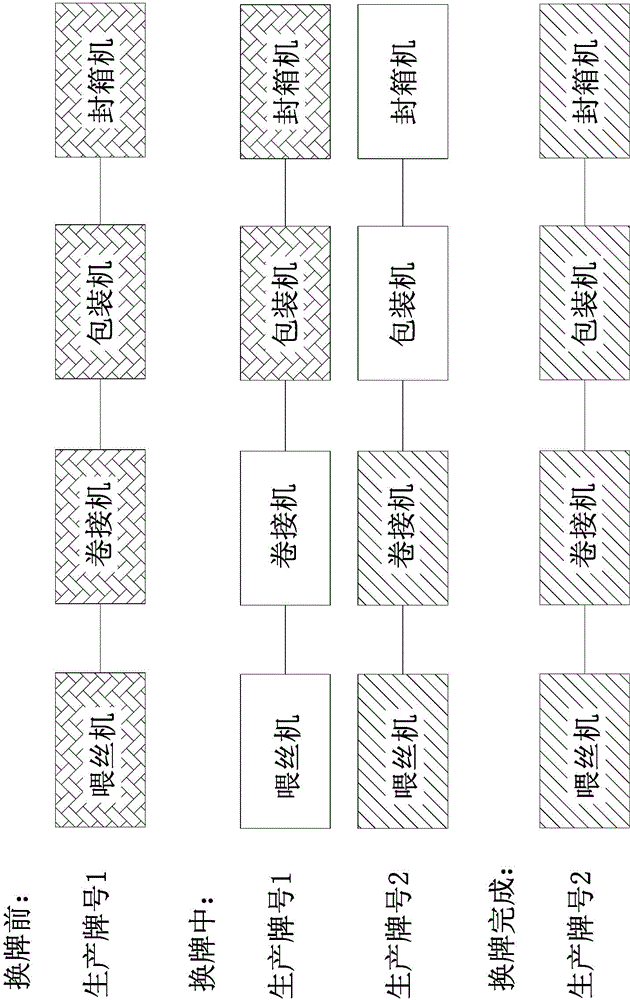

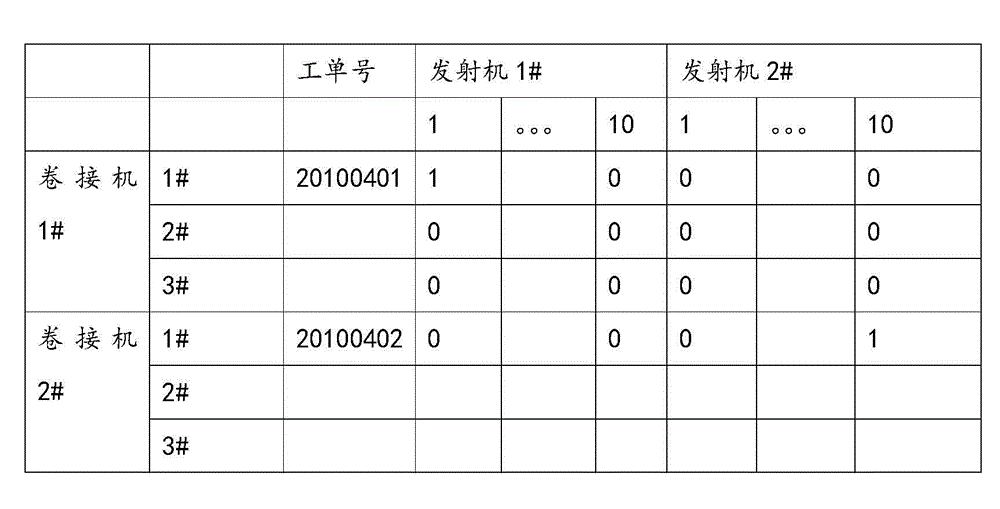

[0015] When the system receives the production work order issued by MES, it disassembles the work order into different production grades, and then builds each virtual production line according to each production grade. The virtual production line, relying on industrial control and industrial Ethernet technology, breaks the traditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com