Multi-circuit integrated comprehensive connection system

A connection system and multi-circuit technology, applied in the direction of connection, two-part connection device, circuit, etc., can solve the problems of difficult human factors, poor electrical performance, and large current value of the input port, etc., to achieve the stability and reliability of the connection Good, good interaction, no effect of sudden current changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

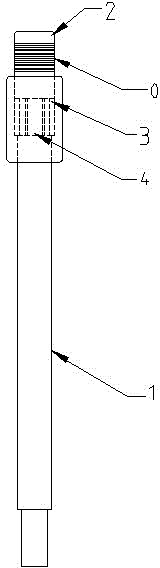

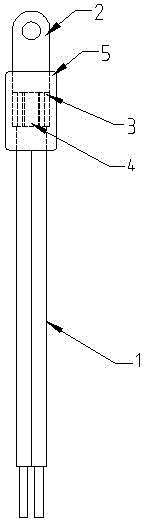

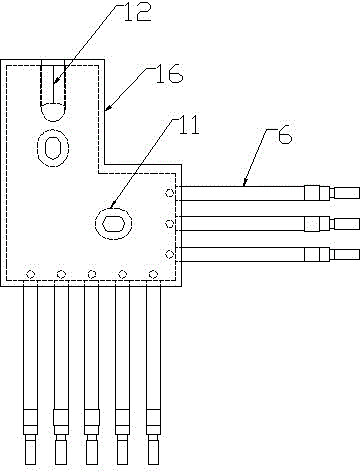

[0050] A multi-circuit integrated comprehensive connection system, especially suitable for the installation and manufacture of electrical devices, complete sets of electrical equipment, etc., especially for the efficient connection of the main switch 21 and many sub-switches 22 when manufacturing and installing switch boxes and distribution boxes a connection system. It includes the main input module A, the main current-carrying module B, and the extended current-carrying module C that may or may not be attached.

[0051] The total input module A is provided with a total input terminal 2 and a bus integration terminal 4, the total input terminal 2 is a current input terminal, the total input terminal 2 has a guide slot 0, and the bus integration terminal 4 is a total input module A current output terminal. The main input end 2 and the bus integration end 4 are connected through the bus transitioner 3 , and the bus integration end 4 connects the current output to the main curr...

Embodiment 2

[0075] Such as figure 1 As shown, the bus connected to the main input module is a single bus, and the upper and lower surfaces of the main input end and the main switch crimping are provided with guide slots, and the direct crimping method is adopted.

Embodiment 3

[0077] Such as figure 2 As shown, there are two buses connected to the main input module, and the main input end adopts the structure of bolt crimping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com