Method and device for conducting media in a brewing system

A medium and equipment technology, applied in the direction of beer brewing, wort preparation, biochemical equipment and methods, etc., can solve the problems of unsatisfactory cleaning of product inlet and product outlet, and achieve the effect of avoiding dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

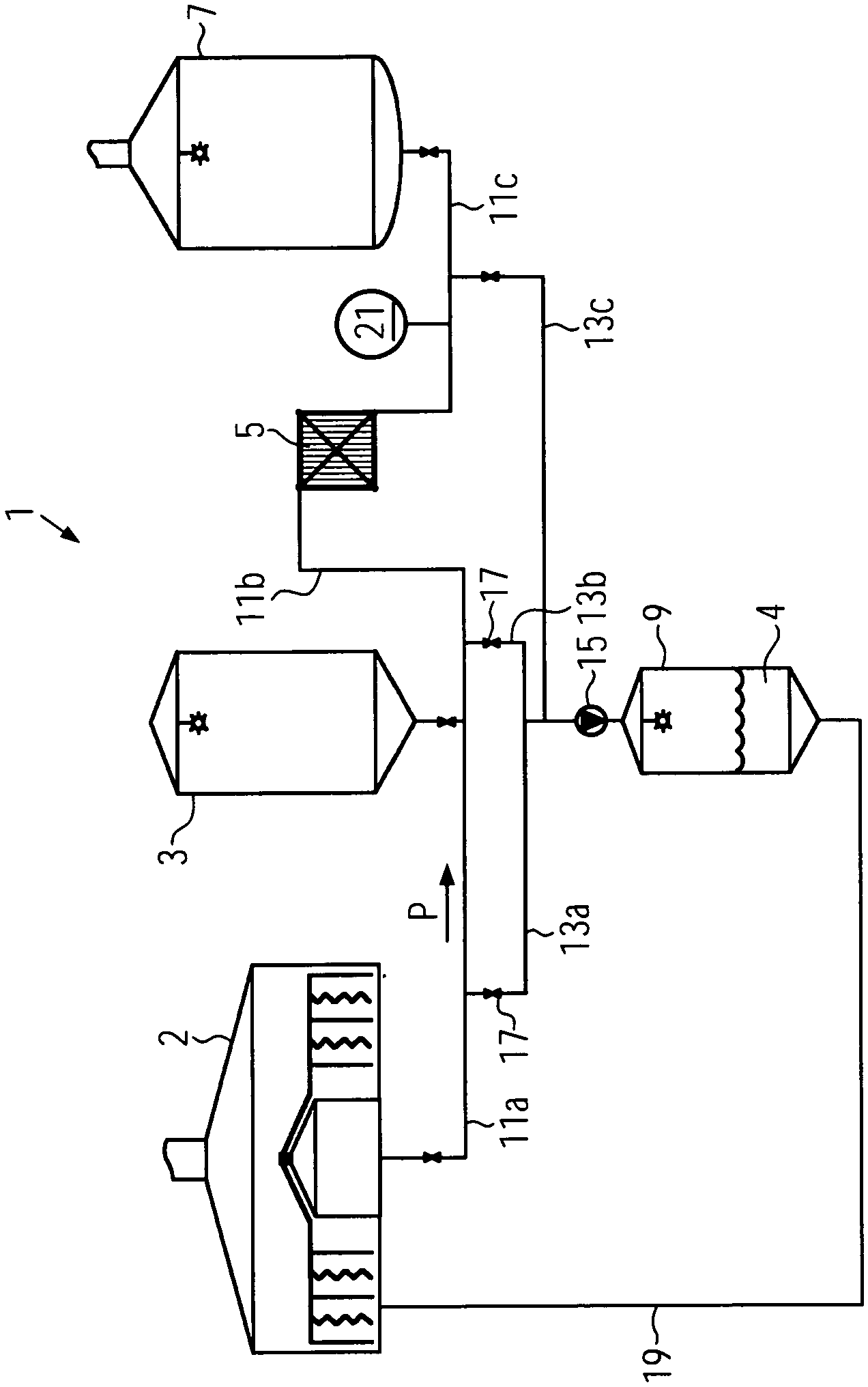

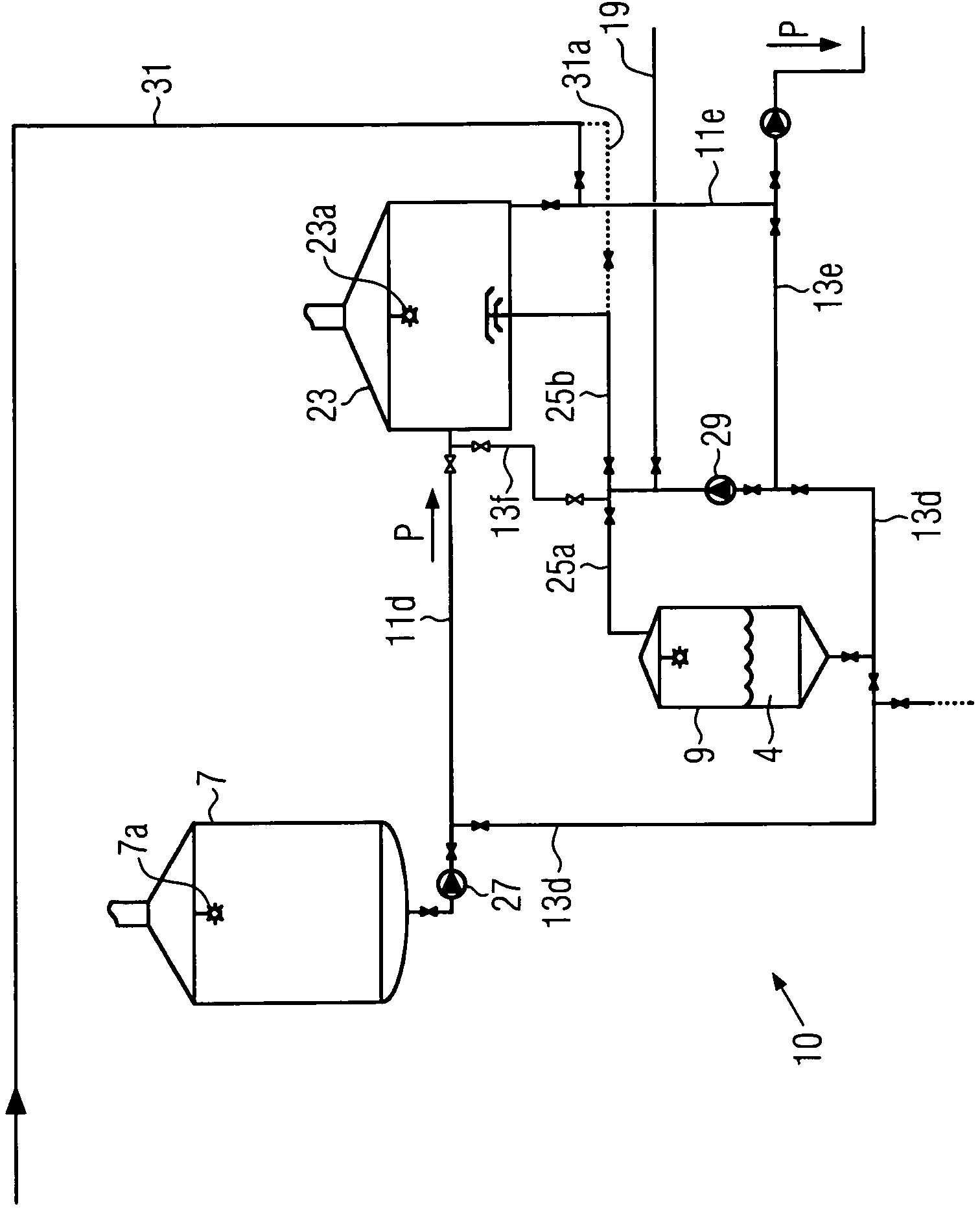

[0029] For clarity, next, with the help of figure 1 and 2 The implementation form will be described separately. However, it is understood that the described embodiments can be combined into a production plant in a brewhouse.

[0030] Depend on figure 1 It can be seen that the first embodiment of the device 1 according to the invention comprises a filter device 2 , an intermediate tank 3 , a heat exchanger 5 , a wort kettle 7 and a surge tank 9 . Between the filter device 2 and the wort kettle 7 a product line 11a to 11c is arranged in each case. These product lines are connected to the buffer tank 9 via respectively associated connecting lines 13 a to 13 c. A common pump 15 is preferably arranged between the connecting lines 13 a to 13 c and the surge tank 9 . Furthermore, for the sake of simplicity, only the flow regulating device or shut-off device 17 is shown, which has possibly associated measuring and regulating devices for determining the quantity and / or flow, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com