Finishing device and method for machining shaft axial bearings

A thrust bearing and finishing technology, which is applied in superfinishing machines, metal processing equipment, manufacturing tools, etc., can solve problems such as unfavorable device costs, and achieve the effects of simple compensation, cost reduction, and high cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

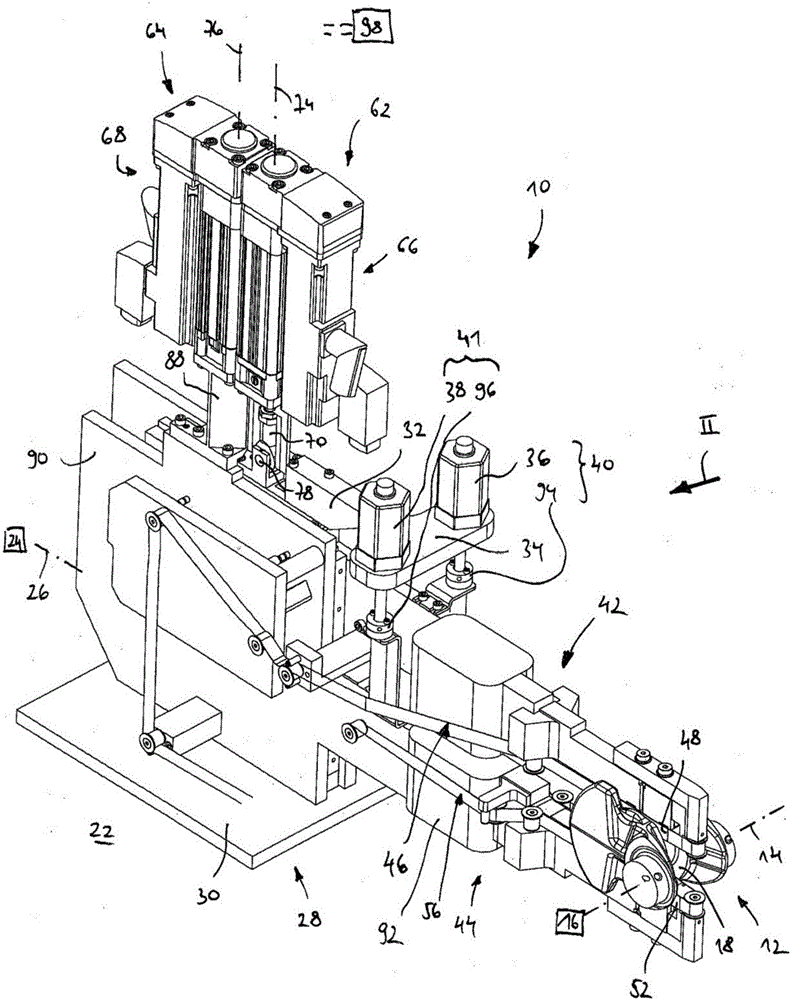

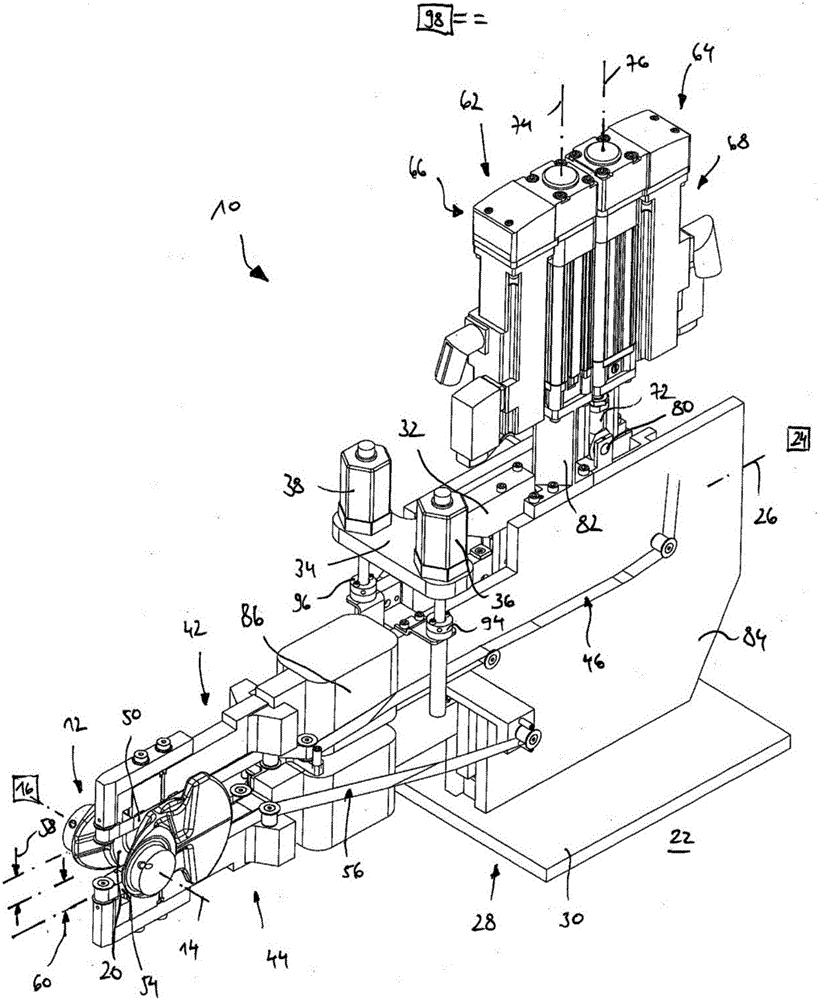

[0027] figure 1 and 2 One embodiment of the finishing device is shown from various angles and is generally designated 10 . The finishing device 10 is used for finishing the thrust bearing surface of a workpiece 12 , which is in particular configured as a crankshaft. The workpiece 12 has an axis 14 . During machining of the workpiece 12 , the workpiece is driven by a schematically shown rotary drive 16 so that the workpiece 12 is rotated about the workpiece axis 14 .

[0028] The workpiece 12 has at least one, preferably two, thrust bearing surfaces 18 and 20 to be machined. The thrust bearing surfaces 18 and 20 together form a crankshaft flange bearing which, when installed in an internal combustion engine, serves to support the crankshaft axially.

[0029] The finishing device 10 is arranged on a known and not shown machine frame 22 . Here, the finishing device 10 is fixed to the machine frame 22 or driven to oscillate along an oscillation axis 26 by a known and schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com