Integrated device for beewax cutting and jelly collecting for obtaining royal jelly

A royal jelly and handle technology is applied in the field of an integrated device for royal jelly cutting, wax and pulp extraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

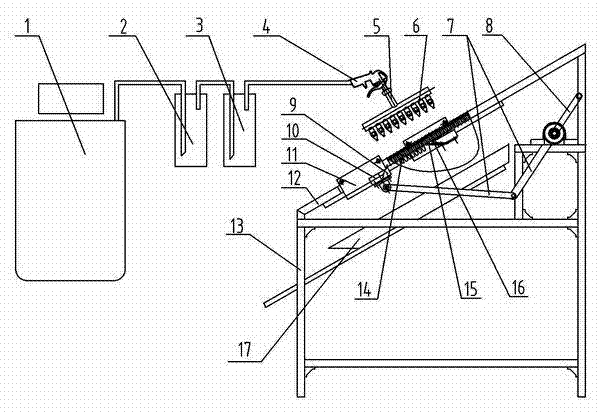

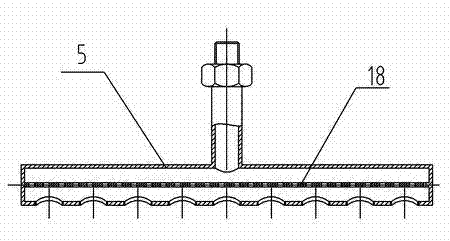

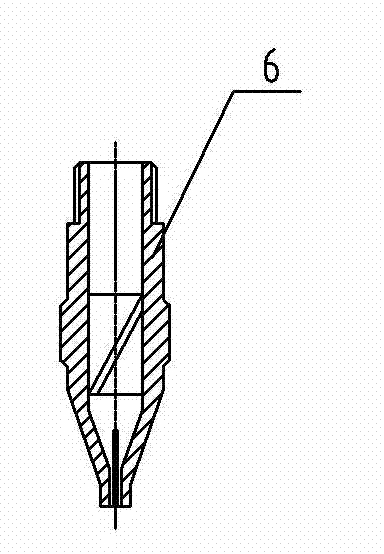

[0011] An integrated device for cutting wax and extracting royal jelly, comprising an air compressor 1, a handle switch 4, a discharge gun barrel 5, a frame 13, a king pedestal 12, a scraper frame 11, a slider 10, a guide rail 9, and a slurry collecting tray 17, The air compressor 1 is connected to the handle switch 4 through the oil filter 2 and the water vapor filter 3 through the hose, and the outlet end of the handle switch 4 is threadedly connected with the discharge gun tube 5, and the inside of the discharge gun tube 5 is equipped with a mesh The turbulent sieve plate 18 is used to turbulence the air flow. The nozzle 6 is evenly installed on the row gun pipe 5 by threads. The nozzle end of the nozzle 6 has a central spout. Eight slits are evenly distributed in the circumferential direction and extend axially to one-half of the cone surface of the nozzle end; the king pedestal 12 is installed on the frame 13 with an inclination of 25-35°, and the pulp production bar 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com