Production method of metallurgical composite channel steel

A production method and composite channel technology, which is applied in the field of composite steel production, can solve the problems of high price of single precious metal alloy channel steel, and achieve the effects of improving material utilization, long service life and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

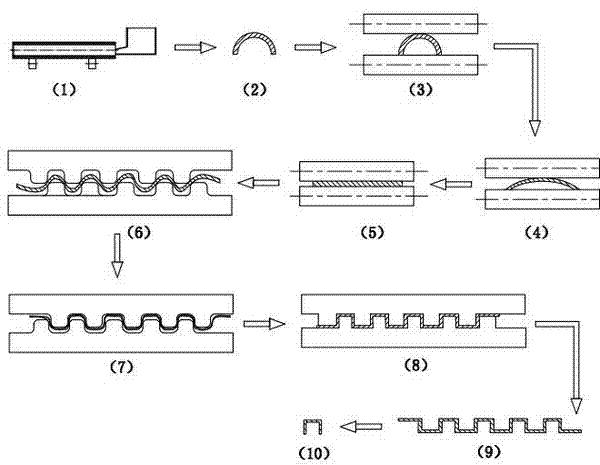

Method used

Image

Examples

example 1

[0039] (1) The composite channel steel base material is 16Mn, the composite layer material is 304, and the product specification is 120mm×53mm×6mm (base layer 4mm+multilayer 2mm).

[0040] (2) Centrifugal casting composite steel pipe slab

[0041] The cast steel billet has an outer diameter of φ580mm, a middle diameter of 446mm, an inner diameter of φ380mm and a length of 3500mm.

[0042] (3) Composite steel pipe billet for rough machining

[0043] The cast composite steel pipe is subjected to internal boring and external peeling processing to remove pores on the external surface and slag layer on the internal surface. The size of the processed steel pipe is φ574mm / φ385mm×3500mm.

[0044] (4) Composite steel pipe billet cutting

[0045] Cut the composite steel pipe billet into two symmetrical arc-shaped plates along the axial direction with a sawing machine or a water jet.

[0046] (5) The curved plate is heated and rolled into a flat plate

[0047] The arc-shaped plate ...

example 2

[0054] (1) The composite channel steel base material is 20MnV, the composite layer material is 321, and the product specification is 140mm×62mm×8mm (base layer 5mm+multilayer 3mm).

[0055] (2) Centrifugal casting composite steel pipe slab

[0056] The cast steel billet has an outer diameter of φ780mm, a middle diameter of 656mm, an inner diameter of φ580mm and a length of 3800mm.

[0057] (3) Composite steel pipe billet for rough machining

[0058] The cast composite steel pipe is subjected to internal boring and external peeling processing to remove pores on the external surface and slag layer on the internal surface. The size of the processed steel pipe is φ774mm / φ586mm×3800mm.

[0059] (4) Composite steel pipe billet cutting

[0060] Cut the composite steel pipe billet into two symmetrical arc-shaped plates along the axial direction with a sawing machine or a water jet.

[0061] (5) The curved plate is heated and rolled into a flat plate

[0062] The arc-shaped p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com