Integral type escalator supporting frame

A technology of escalator and support frame, applied in escalator, transportation and packaging, etc., can solve the problems of complex thermal deformation process of welding process, difficult to correct truss deformation, complicated production and assembly process, etc., so as to improve the single transportation volume. , The structure is simple, novel and unique, and the assembly is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

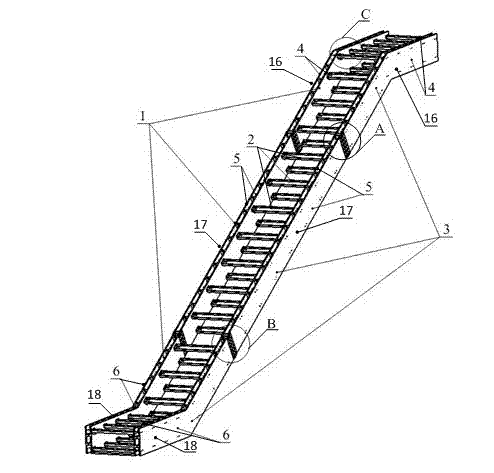

[0026] Such as figure 1 As shown, the integral escalator support frame of the present invention includes a left side plate 1 , an intermediate connecting body 2 and a right side plate 3 . The left side panel 1 and the right side panel 3 are composed of an upper support section 4 , a middle support section 5 and a lower support section 6 respectively.

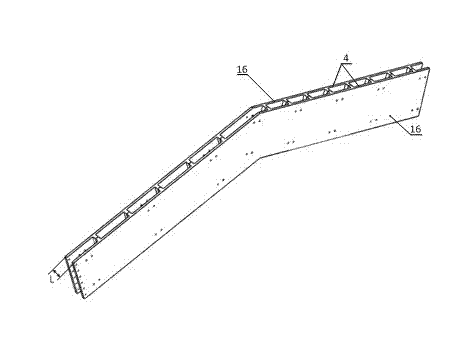

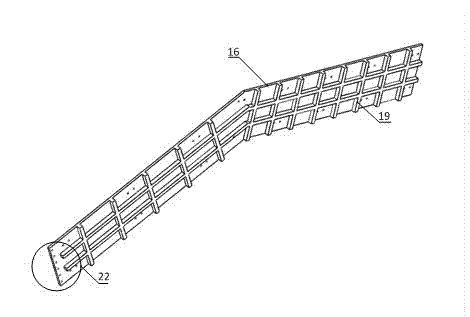

[0027] Such as figure 1 , figure 2 , image 3 , Figure 8 , Figure 10 with Figure 11 As shown, the upper support section 4 comprises two panels 16 fixedly connected together. The panel 16 is preferably a glass steel sheet. Such as image 3 , 5 As shown in and 7, the inner side of each panel 16, 17 and 18 is fixed with a cross-shaped reinforcing rib 19, and the panels 16, 17 and 18 and the cross-shaped reinforcing rib 19 can be integrally formed. The bottom of the upper support section has a connection end 22, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com