Magnetic suspension tentering sizing transmitting unit

A technology of stenter setting and transmission unit, which is applied in textiles and papermaking, fabric surface trimming, fabric elongation, etc., can solve the problems of complex guiding system, etc., and achieve reliability improvement, structure and control system simplification, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

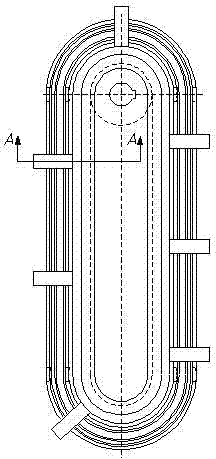

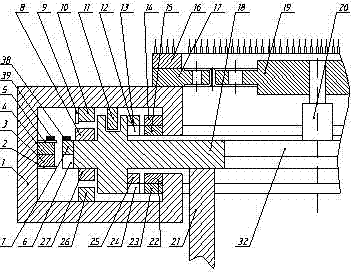

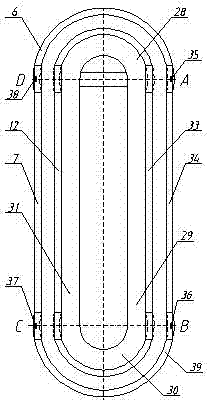

[0025] See attached Figure 1-7 : A magnetic levitation tenter shaping transmission unit, comprising a support 21, a support base 18 is installed on the support 21, support guide rails 8, 27, rectangular guide guide rails 7, 12, 25 and circumferential guide guide rails 6, 13, 24 are installed on the support base 18 , the workbench 1 is set on the support base 18, the gear belt 17 is installed on the workbench 1, the needle felt 16 is installed on the gear belt 17, the motor bracket 32 is installed on a certain arc end of the support base 18, and the rotating motor 20 is installed on the motor bracket 32 , the gear plate 19 is installed on the rotating motor 20, and the gear plate 19 is meshed with the gear belt at its corresponding position. The supporting seat 18 includes two straight sections 29, 31 and two semicircular sections 28, 30. When installing, ensure that the straight sections 29, 31 and semicircular sections 28, 30 are tangent, so that the supporting seat 18 as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com