Sound insulation chock for ship

A choke valve and sound insulation technology, applied in the field of cabin doors, can solve the problems of poor sound insulation effect of door panels, damaged sealing strips, affecting the sealing performance of sound insulation choke valves, etc., so as to reduce friction, improve sound insulation effect, and enhance sealing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

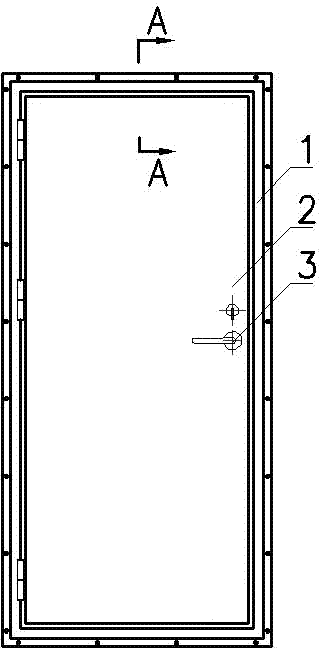

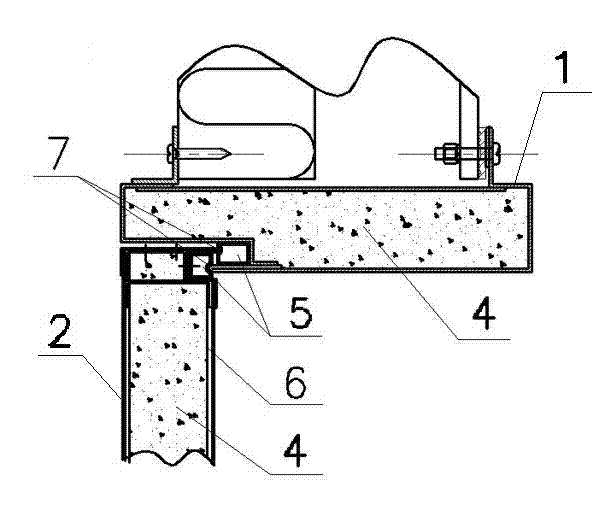

[0014] Such as figure 1 and figure 2 As shown, the ship sound insulation choke of the present invention includes a door panel 2 and a door frame 1, a group of corresponding sides of the door panel 2 and the door frame 1 are hinged together, and there is a locking mechanism 3 between the door panel 2 and the door frame 1 except the hinged sides The locking mechanism 3 can be a single door lock or a multi-point linkage door lock arranged on the opposite side of the hinged side of the door panel 2 and the door frame 1. Other positions outside are provided with multi-point linkage door locks. In this embodiment, a single door lock is set on the opposite side of the hinged side of the door panel 2 and the door frame 1 to realize the locking between the door panel 2 and the door frame 1. The door panel 2 and the door frame 1 can be made of high-strength materials, such as stainless steel, aluminum alloy and other metal materials. The door panel 2 and the door frame 1 in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com