Light guiding system, side-inlet type backlight module and liquid crystal display

A light introduction and collection system technology, applied in light guides, instruments, optics, etc., can solve the problems affecting the optical quality of the backlight module, the influence of component functions, and large brightness differences, so as to improve the optical quality, life span, and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

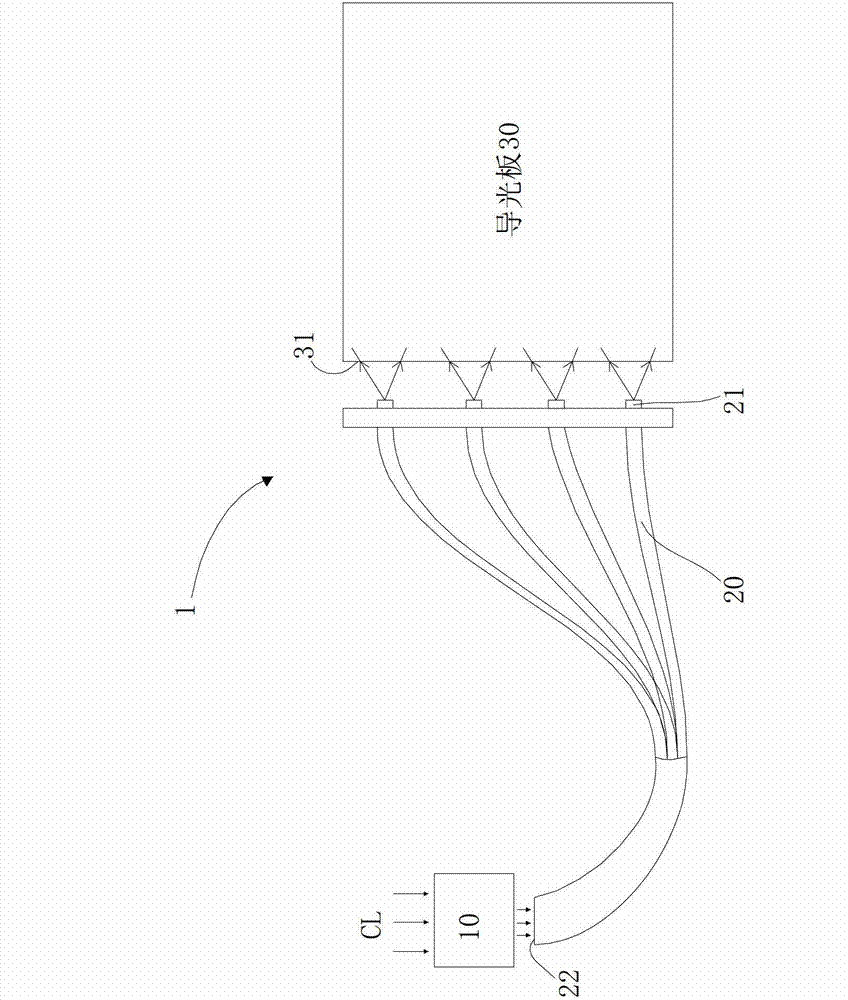

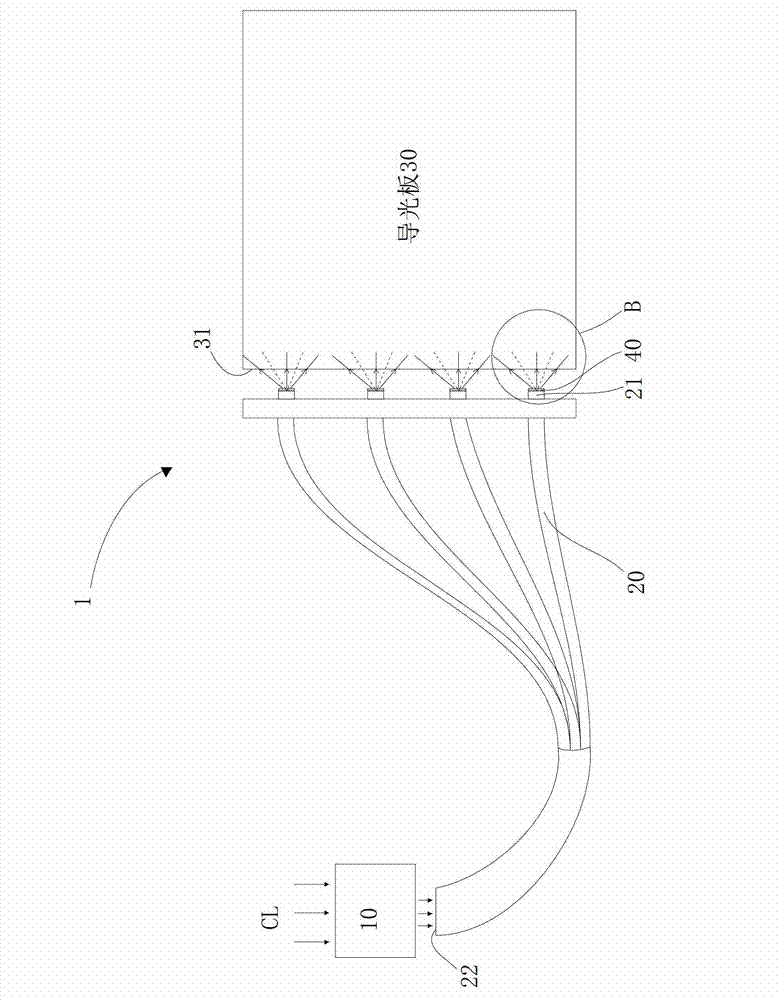

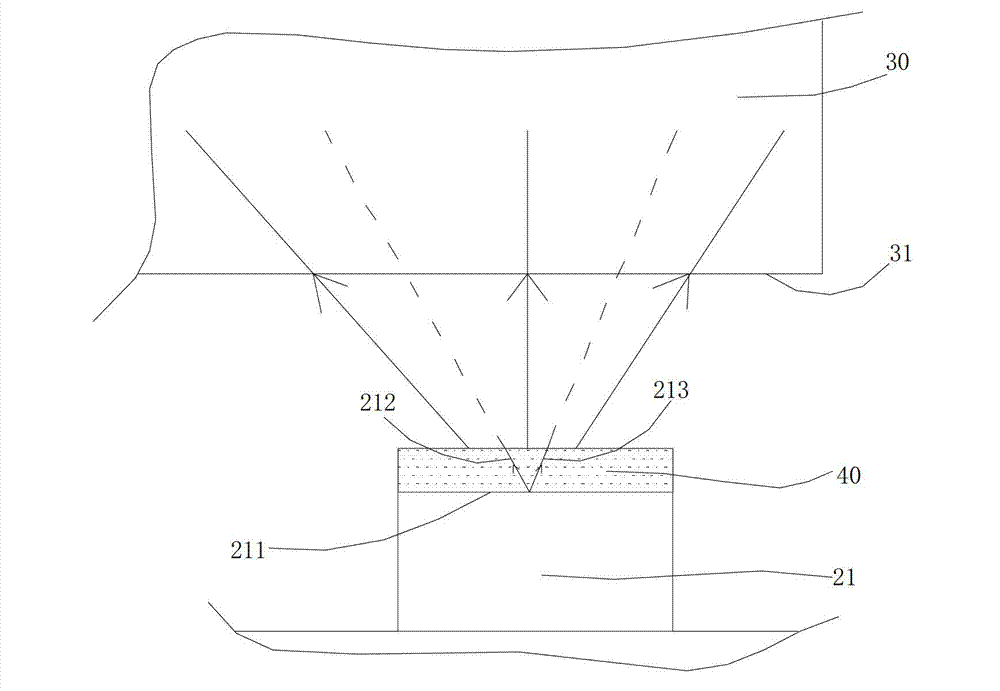

[0024] refer to figure 2 , The light introduction system 1 includes an ambient light collection system 10 , several optical fibers 20 , and a fluorescent film 40 . The ambient light collection system 10 faces and absorbs the ambient light CL. It should be noted that the ambient light CL can be sunlight, light, or light emitted by other luminous objects. Each optical fiber 20 has a light output end 21 and a light input end 22. The light input ends 22 of each optical fiber converge into a bundle and are adjacent to the ambient light collection system 10. The light output ends 21 of each optical fiber are arranged adjacent to the light guide plate 30. The light-incident side 31, it should be noted that the number and arrangement of the light-emitting ends 21 are not the same as figure 2 What is shown in is limited, but the number and arrangement of the light-emitting ends 21 are determined according to the actual situation. The light emitting surface 211 of each light emittin...

Embodiment 2

[0029] refer to Figure 4 The difference between Embodiment 2 and Embodiment 1 is that the fluorescent film 40 can also be arranged on the light-incident side 31 of the light guide plate 30, and the scattering particles contained in the fluorescent film 40 will diffuse the light beam passing through the fluorescent film 40, that is, the light 212 , 213 are diffused and spread along the solid line, so that the light beam emitted from the light-emitting surface 211 is diffused.

Embodiment 3

[0031] refer to Figure 5a and Figure 5b , the fluorescent film 40 also has other settings. For example, a cover body 90 can be provided at a position relative to each light-emitting end 21, and the cover body 90 includes an inner wall 91 facing the light-emitting end 21 and an outer surface 92 facing away from the light-emitting end 21, and the fluorescent film 40 can be arranged on the On the inner wall 91 or on the outer surface 92, the scattering particles contained in the fluorescent film 40 diffuse the light beam passing through the fluorescent film 40, that is, the light rays 212, 213 are scattered and diffused and propagate along the solid line, and then the light emitting surface 211 is emitted. beam is diffused. Of course, in this embodiment, the shape of the cover body 90 is not limited to the circle shown in the figure, for example, it can also be oval, square and so on.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com