Method for changing number of tube passes of tube type heat exchanger

A tube-and-tube heat exchanger and heat exchanger technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of heavy workload and large investment in transformation, and achieve simple transformation methods , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A modification method for the number of tube passes of a two-tube shell-and-tube heat exchanger.

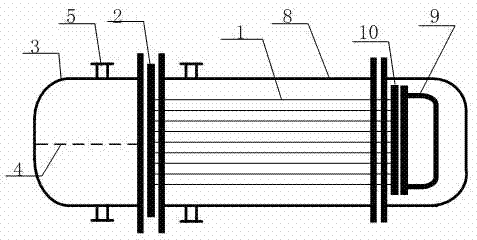

[0025] Such as figure 1 As shown, the existing tube-and-tube heat exchanger consists of a tube bundle 1, a first tube plate 2, a tube box with a nozzle side with a nozzle side 3, a nozzle 5, a groove or rib 6, and a side without a nozzle without a tube The nozzle side pipe box 9 and the second tube plate 10 are composed, wherein: the pipe nozzle 5 is welded on the outside of the nozzle side pipe box 3, and the inside of the two nozzle side pipe boxes 3 and 9 are welded with partitions 4. There are generally 2-4 nozzles 5, the tube bundle 1 is located in the shell 8, and the two ends of the tube bundle 1 are respectively connected to the first tube sheet 2 and the second tube sheet 10, and the first tube sheet 2 and the second tube sheet 10 Grooves or ribs 6 are provided on the top.

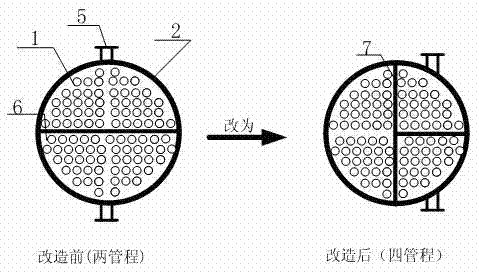

[0026] Such as figure 2 , 3 , 4 and 5, the transformation method is fir...

Embodiment 2

[0030] Embodiment 2: A modification method for the number of tube passes of a four-tube shell-and-tube heat exchanger.

[0031] Such as figure 1As shown, the existing tube-and-tube heat exchanger consists of a tube bundle 1, a first tube plate 2, a tube box with a nozzle side with a nozzle side 3, a nozzle 5, a groove or rib 6, and a side without a nozzle without a tube The nozzle side pipe box 9 and the second tube plate 10 are composed, wherein: the pipe nozzle 5 is welded on the outside of the nozzle side pipe box 3, and the inside of the two nozzle side pipe boxes 3 and 9 are welded with partitions 4. There are generally 2-4 nozzles 5, the tube bundle 1 is located in the shell 8, and the two ends of the tube bundle 1 are respectively connected to the first tube sheet 2 and the second tube sheet 10, and the first tube sheet 2 and the second tube sheet 10 Grooves or ribs 6 are provided on the top.

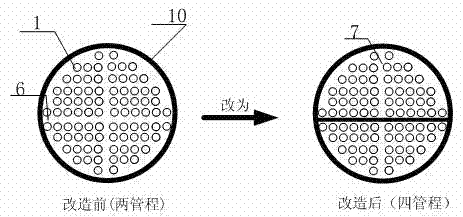

[0032] Such as Image 6 , 7 , 8 and 9, the transformation method is firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com