Efficient heat exchanger

A heat exchanger and high-efficiency technology, applied in the industrial field, can solve the problems of low heat exchange efficiency, underutilized heat carrier, large pressure loss, etc., and achieve the effects of small pipeline pressure loss, simple structure and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

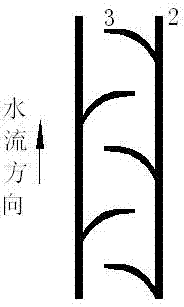

[0023] A high-efficiency heat exchanger of the present invention adopts large-diameter pipelines, and a number of turbulent flow devices are arranged inside the pipelines. The turbulent flow devices are planar sheets or curved sheets of any shape, and the included angle with the direction of water flow is less than 90°.

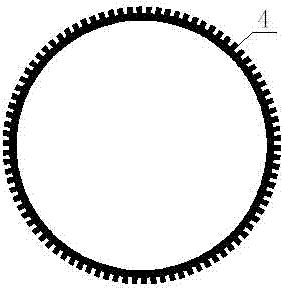

[0024] Measures are taken to increase the specific surface area on the outer wall of the pipeline, and protrusions to increase the heat dissipation area are arranged in the axial direction. The protrusions are in any shape, such as protrusion points, protruding lines, etc. Roads are in close contact or as one.

[0025] The material of the pipeline is a material with high thermal conductivity, such as stainless steel and aluminum alloy.

[0026] The transverse section of the pipeline is in any shape, such as circular, square, rhombu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com