Abrasion tester for cylinder sleeve-piston ring friction pair

A wear test, piston ring technology, applied in the test of wear resistance, the test of mechanical parts, the test of machine/structural parts, etc., can solve the problems of high cost, long test period, increased test period and test cost, etc. The effect of uniform circumferential load, strong bearing capacity and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and principle of the present invention will be further explained below with reference to the drawings and embodiments. It should be noted that this embodiment is narrative rather than limiting, and does not limit the scope of protection of the technical solution of the present invention.

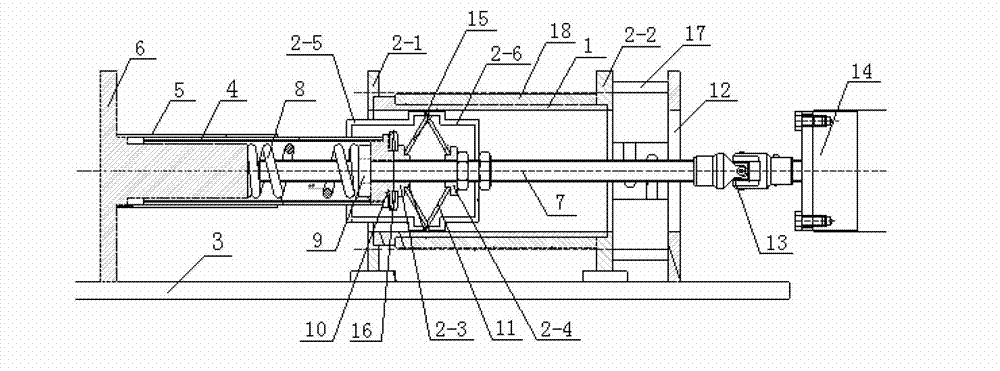

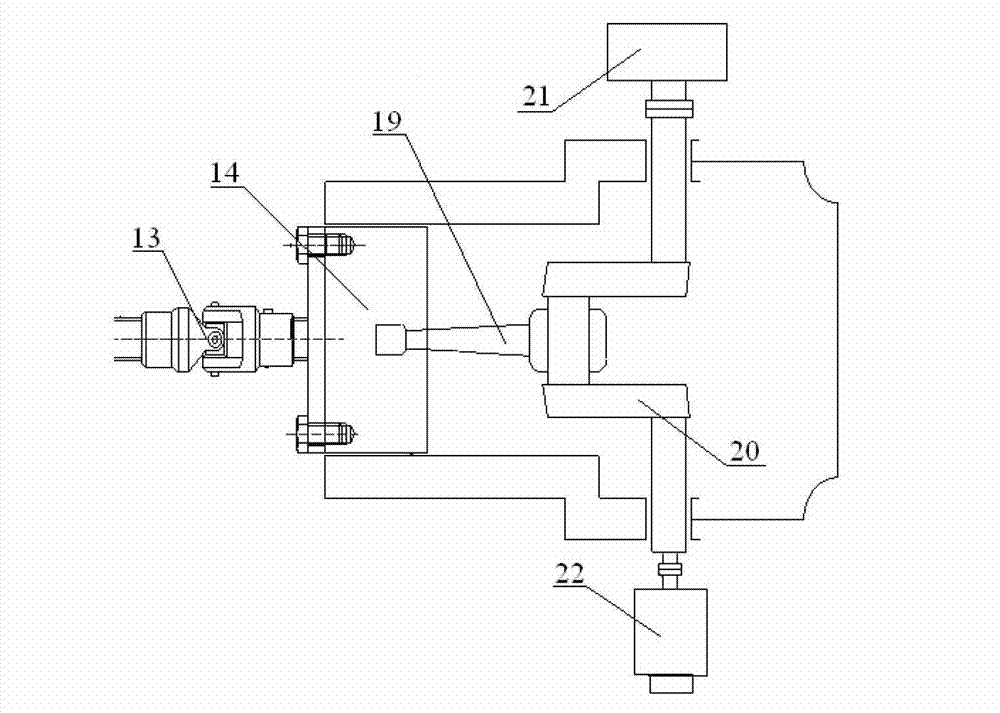

[0022] The specific technical characteristics of the cylinder liner-piston ring friction pair wear tester are: the cylinder liner 1 is fixed between the first positioning frame 2-1 and the second positioning frame 2-2, and the first and second positioning frames are Fixed on the sliding block of the guide rail 3. The inner sleeve 4 is placed in the outer sleeve 5, and the outer sleeve is connected with the compression spring base 6 through threads, and the compression spring base is fixed to the guide rail. Compression spring 8, piezoelectric crystal 9, positioning sleeve 10, third positioning frame 2-3, double ring elastic support rod 11, fourth positioning frame 2-4, cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com