Test system and test method of electric automobile high-voltage electric system

A high-voltage electrical and electric vehicle technology, used in circuit breaker testing, dielectric strength testing, measuring devices, etc. Unprofessional problems, etc., achieve the effect of eliminating the defects of non-standard testing, promoting the unification of testing methods and testing standards, and increasing operability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand, the present invention will be described in further detail below in conjunction with embodiment:

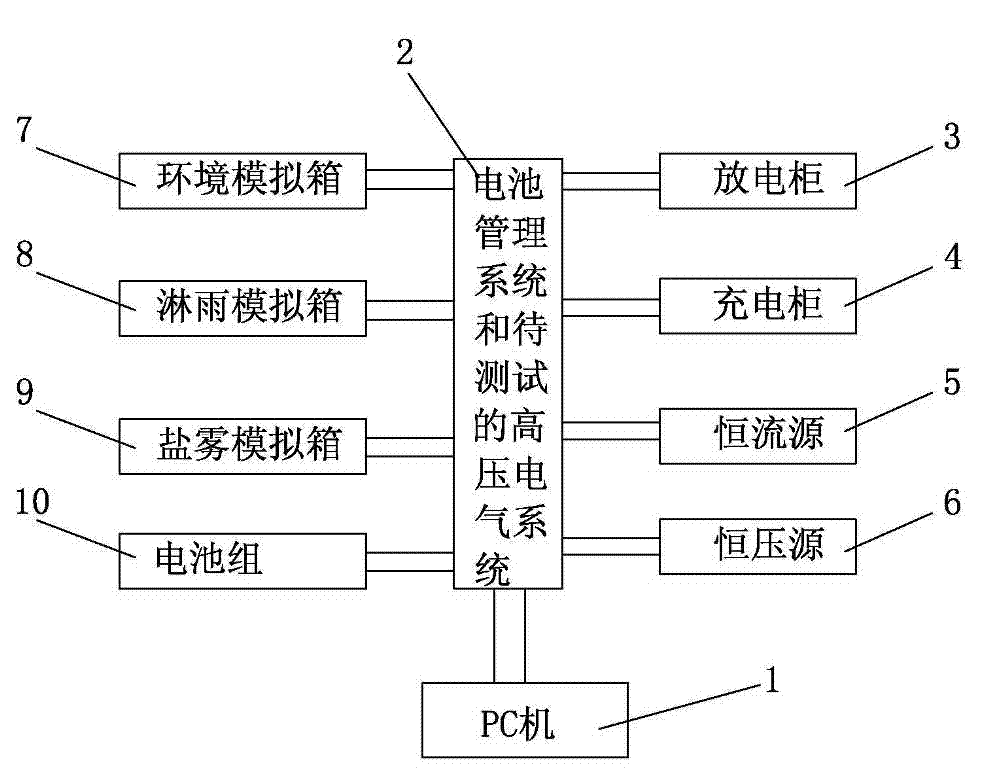

[0024] as attached figure 1 Shown is a composition principle diagram of the electric vehicle high-voltage electrical system test system disclosed in this embodiment. The test system includes a main-controlled PC 1, a battery management system controlled by the PC 1, a high-voltage electrical system 2 to be tested, a discharge cabinet 3 for simulating the discharge process, a charging cabinet 4 for simulating the charging process, and a constant current for generating Constant current source 5, constant voltage source 6 for generating constant voltage, environment simulation box 7 for simulating set temperature and humidity environment, rain simulation box 8 for simulating rain environment, and simulating salt spray The environmental salt spray simulation box 9 and the battery pack 10 for testing, and a CAN card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com