Miniaturized large-current handcart-type vacuum circuit breaker

A technology of vacuum circuit breaker and vacuum circuit breaker, applied in high-voltage air circuit breaker, high-voltage/high-current switch, circuit and other directions, can solve the problems of vacuum degree drop of vacuum interrupter, failure to work normally, increase of related cost, etc. The effect of shrinkage, improved reliability, and reduced chance of mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

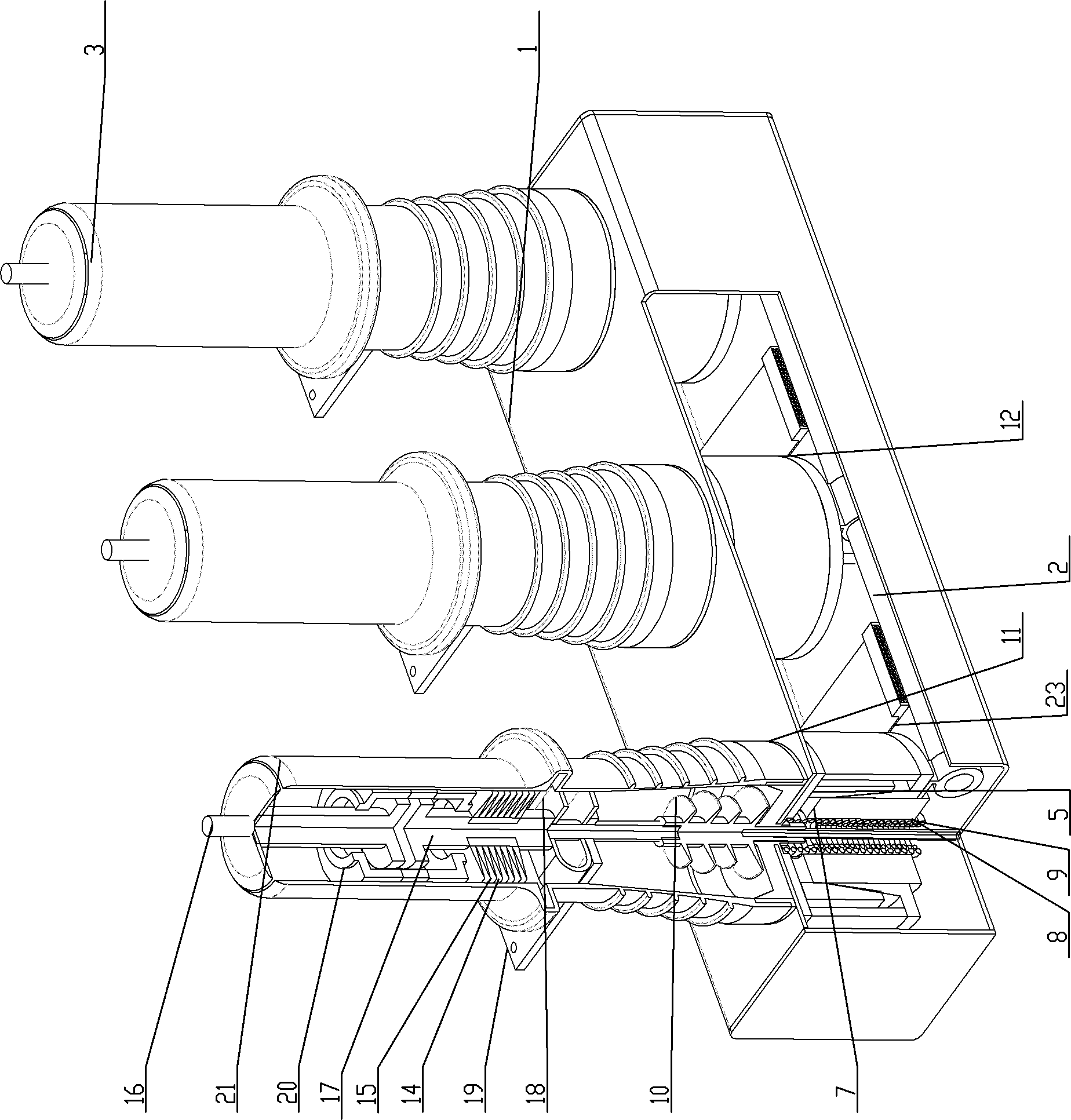

[0026] like figure 1 As shown, this embodiment includes a frame main body 1, a three-phase vacuum breaking pole 3, a synchronous shaft 2 and its auxiliary contact 23, the three-phase vacuum breaking pole 3 is arranged on the upper part of the frame main body 1, and the synchronous shaft 2 And its auxiliary contact 23 is set on the side of the frame main body 1. The three-phase vacuum circuit breaker pole 3 is provided with a vacuum interrupter, an insulating rod 10, and a permanent magnet operating mechanism vertically and sequentially from top to bottom. The vacuum interrupter includes an upper terminal 16, a lower terminal 19, a bellows 14 and a ceramic chamber 20, the bellows 14 is arranged outside the ceramic chamber 20 and connected to the lower end of the ceramic chamber 20; one end of the insulating rod 10 is connected to The moving contact 17 is connected, and the moving contact 17 cooperates with the bellows 14, and the other end is connected with the permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com