Axial-segmented solid permanent-magnet rotor

A technology of axially segmented and permanent magnet rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of poor ventilation, high temperature, irreversible demagnetization of permanent magnets, etc., and achieve simple structure , improve the service life and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

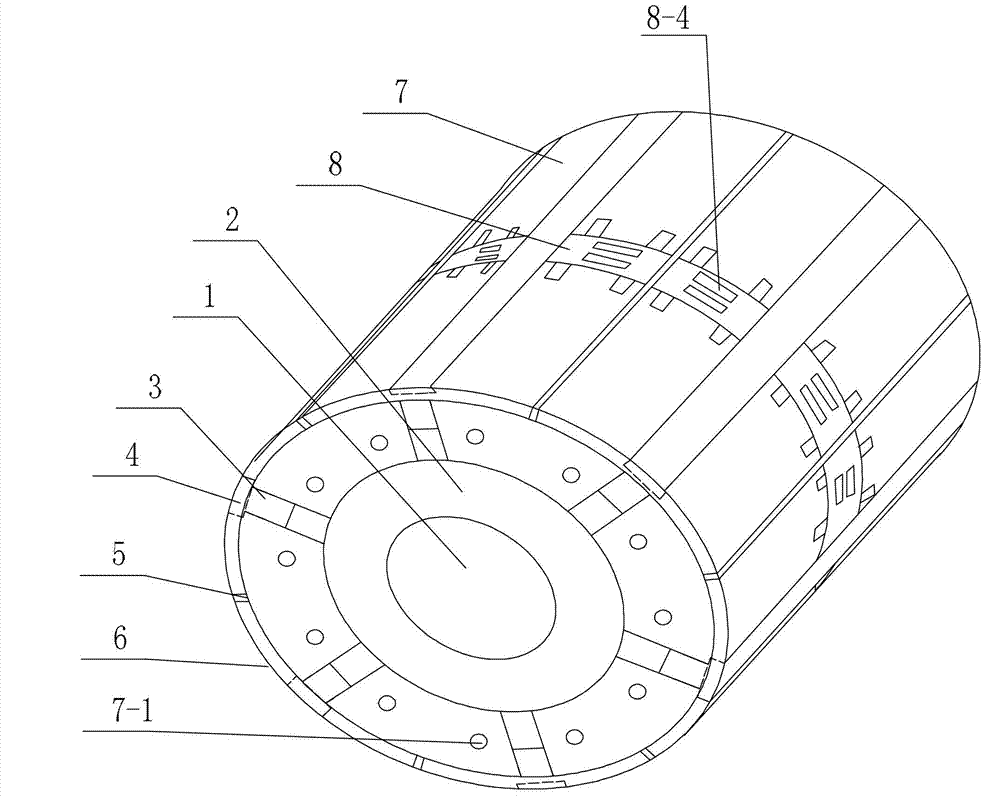

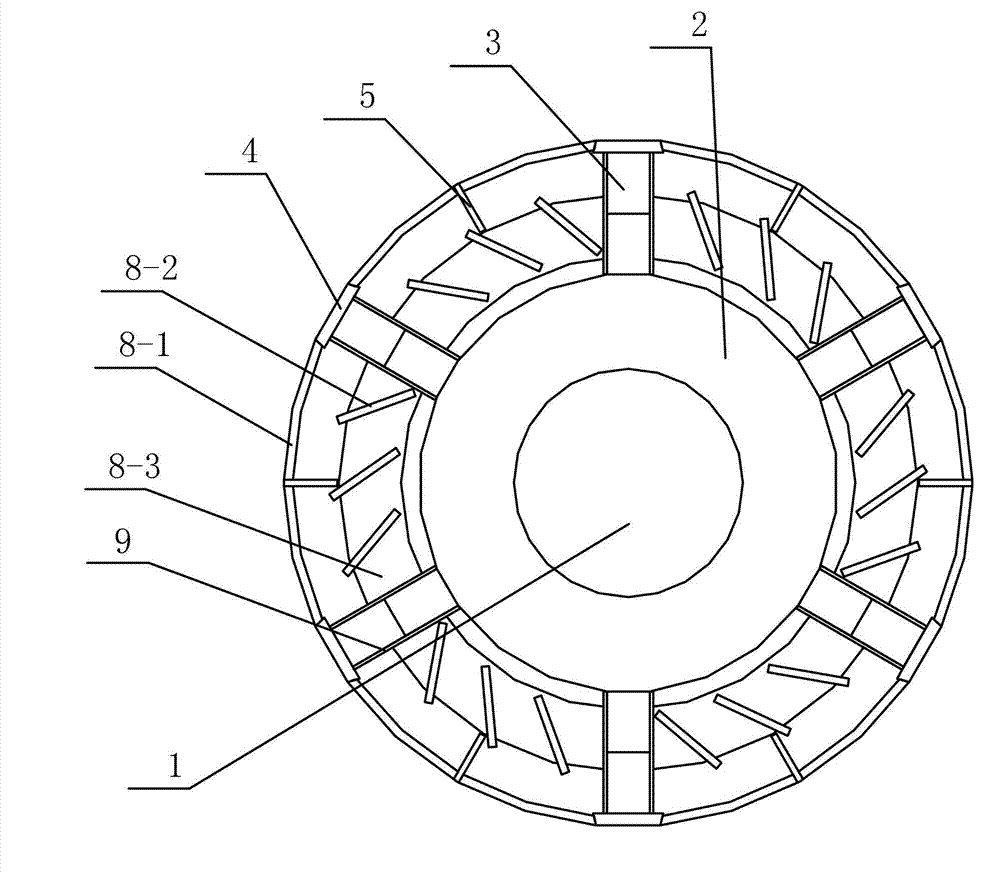

[0021] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the axially segmented solid permanent magnet rotor described in this embodiment includes a rotating shaft 1, and it also includes a magnetic isolation ring 2, a plurality of permanent magnets 3, a plurality of permanent magnet slot wedges 4, and a plurality of starting magnets. Cage bars 5, two cage bar end rings 6, two rotor axial segments 7 and air guides 8, the number of permanent magnets 3, permanent magnet slot wedges 4 and starting cage bars 5 is the same, and the two rotor shafts To the same structure as segment 7,

[0022] The magnetic isolation ring 2 is sleeved on the outer circular surface of the rotating shaft 1, the two rotor axial segments 7 are axially sleeved on the outer circular surface of the magnetic isolation ring 2, and the two rotor axial segments 7 pass through The air guiding parts 8 are connected together,

[0023] Each rotor axial se...

specific Embodiment approach 2

[0034] Specific implementation mode two: the following combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. Two rectangular ventilation holes 8-4 are provided on the upper connecting ring section 8-1, and the two rectangular ventilation holes 8-4 are arranged along the axial direction. arrangement.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. An insulating plate 9 is provided between the contact surfaces of the permanent magnet 3 and the circumferential segment of the rotor.

[0036] The arrangement of the insulating plate can prevent the permanent magnet 3 from running in series when the motor is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com