A kind of preparation method of low phytic acid calcium-tolerant soybean protein

A technology of soybean protein and phytic acid, which is applied in the field of food processing, can solve problems affecting food quality, affecting protein extraction rate, affecting protein calcium resistance, protein functional properties, etc., to weaken electrostatic interaction, reduce membrane fouling, and improve Effect of protein retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

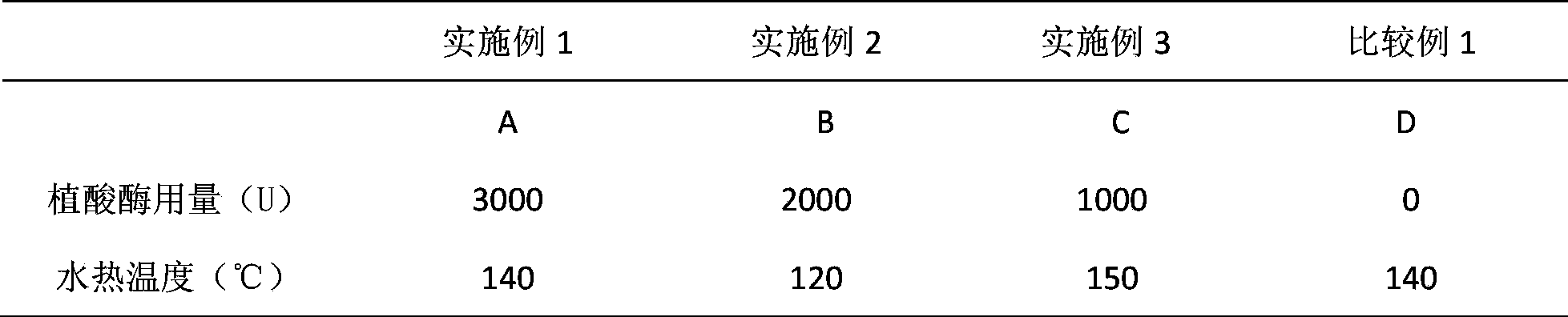

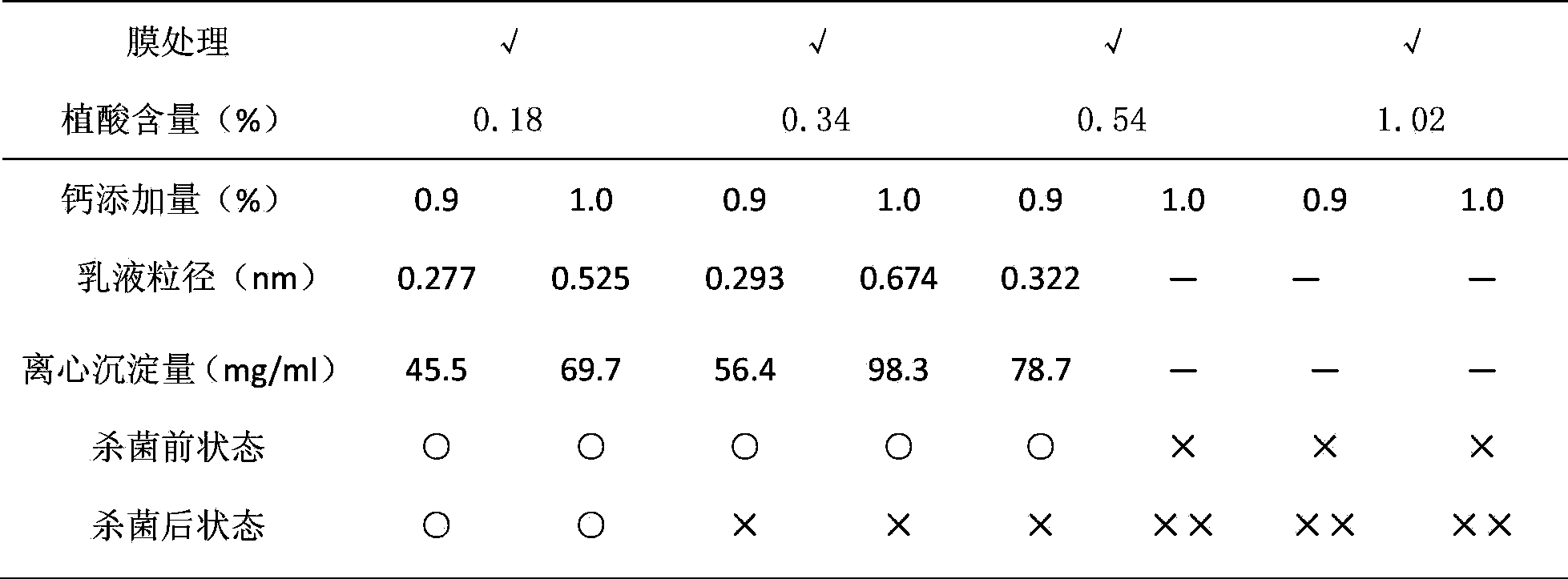

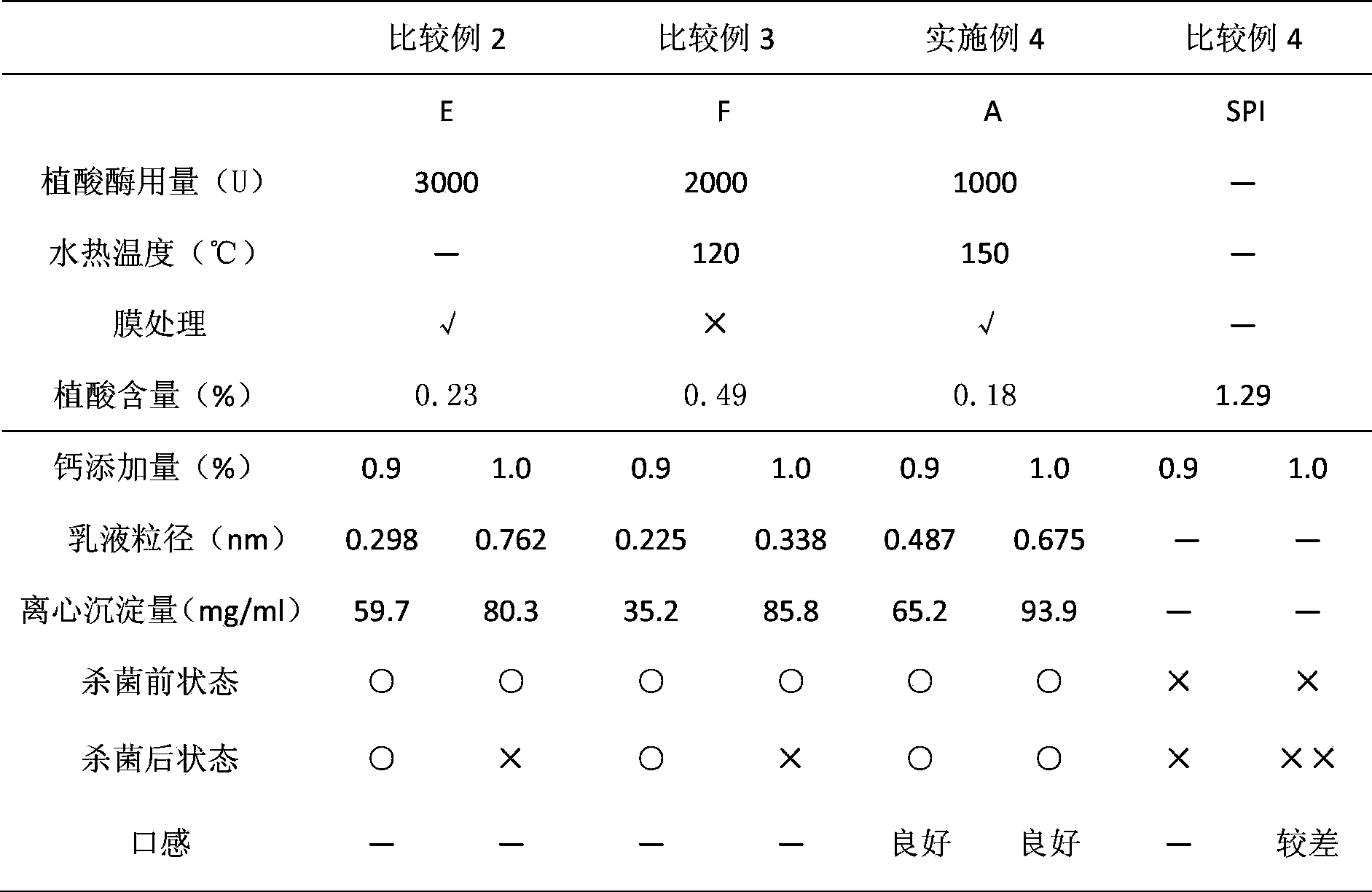

Embodiment 1

[0025] A preparation method of low phytic acid and calcium-tolerant soybean protein: mix defatted soybean flour (g) with water (ml) in a mass volume ratio of 1:10, fully stir and control the temperature to 50°C, add phytase and adjust the temperature with hydrochloric acid When the pH value reaches 4.5, the amount of phytase is 3000U (relative to each gram of soybean flour) and is treated with phytase for 2 hours under stirring, then the pH is adjusted to 8.0 with sodium hydroxide, and after stirring, it is homogenized in a colloid mill for 10 minutes to obtain The defatted soy flour slurry; the defatted soy flour slurry is subjected to jet cooking heat treatment, the treatment temperature is 140 ° C, and the time is 90 s; the jet cooking slurry is adjusted to pH 7.5 with sodium hydroxide, and the obtained heat treated slurry is cooled to 25 ° C. Centrifuge for 30min at a speed of 3000rpm; take the centrifuged supernatant, adjust the pH of the supernatant to 4.5 with hydrochlor...

Embodiment 2

[0027] A preparation method of low phytic acid and calcium-resistant soybean protein: mix defatted soybean powder (g) with water (ml) in a mass-volume ratio of 1:15, fully stir and control the temperature to 50°C, add phytase and adjust the temperature with hydrochloric acid The pH value is 5.5, and the amount of phytase is 2000U (relative to each gram of soybean flour) and is treated with phytase for 2 hours under stirring, and the pH is adjusted to 8.5 with sodium hydroxide, and after stirring, it is homogenized in a colloid mill for 30 minutes, and the obtained Defatted soy flour slurry; heat-treat the defatted soy flour slurry by jet cooking at a temperature of 120°C for 10s; adjust the pH value of the jet-cooked slurry to 8.5 with sodium hydroxide, cool the resulting heat-treated slurry to 25°C, and centrifuge Treat for 30 minutes with a centrifugation speed of 3000rpm; take the centrifuged supernatant, adjust the pH of the supernatant to 4 with hydrochloric acid, re-disso...

Embodiment 3

[0029] A preparation method of low phytic acid and calcium-resistant soybean protein: mix defatted soybean powder (g) with water (ml) in a mass-volume ratio of 1:15, fully stir and control the temperature to 50°C, add phytase and adjust the temperature with hydrochloric acid The pH value is 4.5, and the amount of phytase is 1000U (relative to each gram of soybean flour) and is treated with phytase for 2 hours under stirring, and the pH is adjusted to 7.5 with sodium hydroxide, and after stirring, it is homogenized in a colloid mill for 30 minutes to obtain Defatted soy flour slurry; heat-treat the defatted soy flour slurry by jet cooking at a temperature of 150°C for 100s; adjust the pH of the jet-cooked slurry to 7.5 with sodium hydroxide, cool the resulting heat-treated slurry to 25°C, and centrifuge Treat for 30 minutes, centrifuge at a speed of 3000rpm; take the centrifuged supernatant, adjust the pH of the supernatant to 4.5 with hydrochloric acid, re-dissolve the precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com