Cleaning agent composition and cleaning method for reverse osmosis membrane

A technology of reverse osmosis membrane and composition, which is applied in the field of cleaning agent composition, can solve problems such as cleaning schemes not mentioned, and achieve the effects of good biodegradation performance, good cleaning and decontamination ability, and strong lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example is used to illustrate the cleaning composition of the present invention and the cleaning method of the reverse osmosis membrane.

[0045] Weigh 1 kg of dodecyl alcohol polyoxyethylene ether (purchased from Jiangsu Haian Petrochemical Company, brand E-1206), acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropylsulfonic acid copolymer (purchased from Taihe Water Treatment Co., Ltd., Shandong Province, brand TH-613) 3.5g, add 70kg deionized water, stir to make it fully dissolved, add deionized water to a solution weight of 100kg, and adjust the pH value with NaOH to be 11.0, A cleaning solution L1 is obtained.

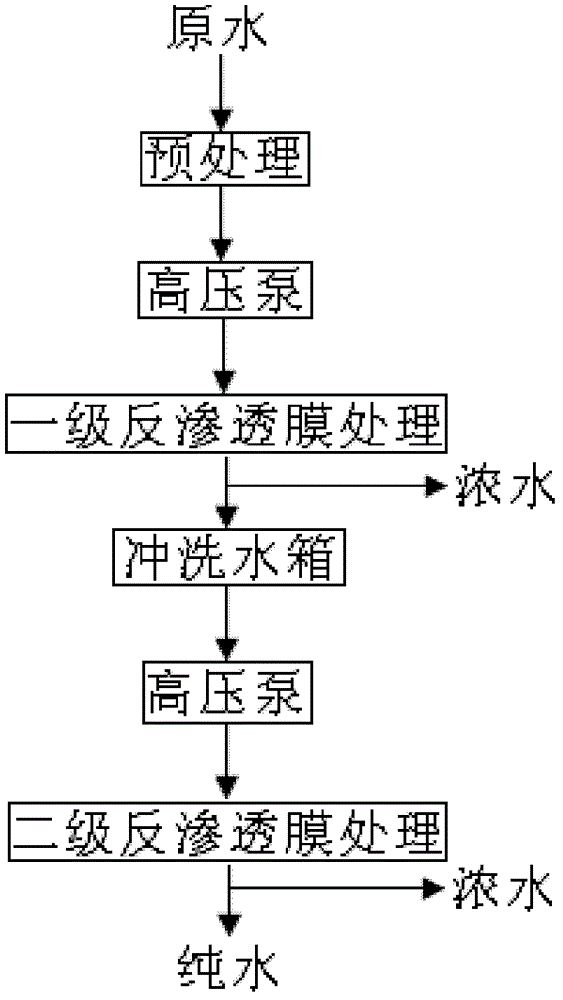

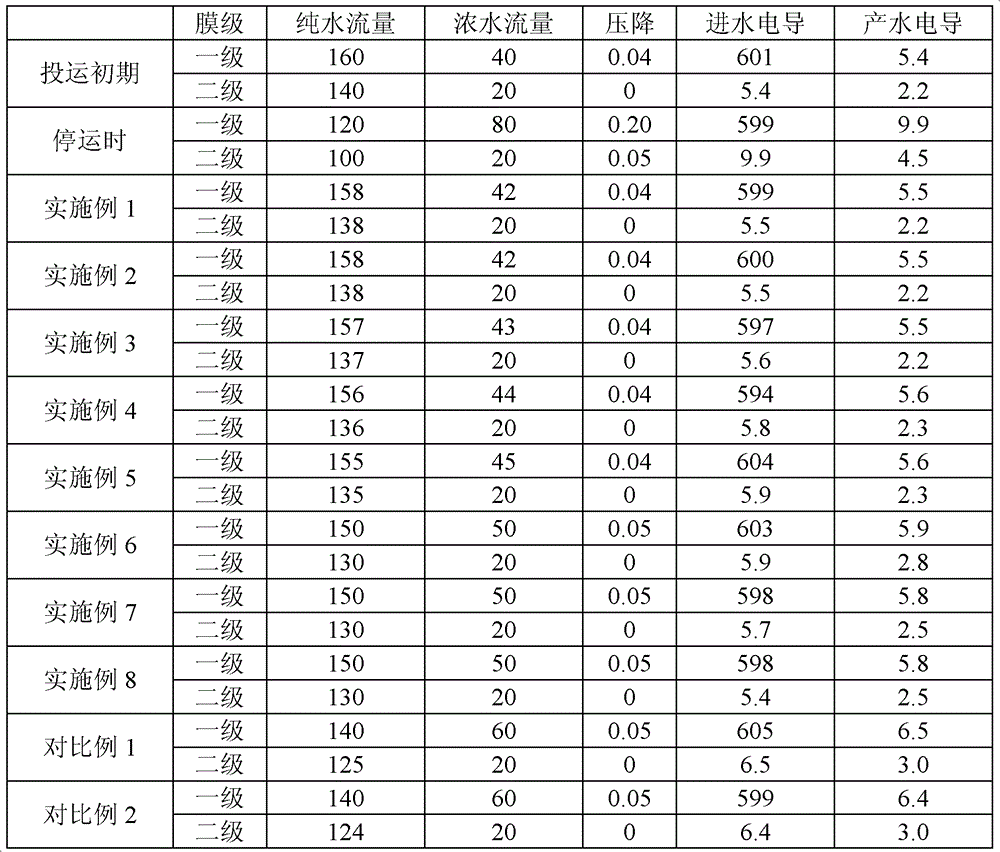

[0046] according to figure 1 In the process shown, a two-stage two-stage reverse osmosis system is used to treat the raw water whose water quality parameters are shown in Table 1. The water treatment capacity is 200L / h until the pressure difference between the front and back of the first-stage reverse osmosis membrane increases by 20% or pur...

Embodiment 2

[0060] This example is used to illustrate the cleaning composition of the present invention and the cleaning method of the reverse osmosis membrane.

[0061] Weigh 2.7 kg of dodecyl alcohol polyoxyethylene ether (purchased from Jiangsu Haian Petrochemical Factory Company, brand E-1206), acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropylsulfonic acid copolymerization (purchased from Shandong Taihe Water Treatment Co., Ltd., brand TH-613) 5.5g, add 70kg deionized water, stir to make it fully dissolved, add deionized water until the solution weight is 100kg, and adjust the pH value to 11.2 with KOH , to obtain cleaning solution L2.

[0062] The reverse osmosis membrane in the two-stage two-stage reverse osmosis system was cleaned according to the method of Example 1, except that the cleaning solution L1 used in Example 1 was replaced with cleaning solution L2.

Embodiment 3

[0064] This example is used to illustrate the cleaning composition of the present invention and the cleaning method of the reverse osmosis membrane.

[0065] Weigh 1.3 kg of dodecyl alcohol polyoxyethylene ether (purchased from Jiangsu Haian Petrochemical Company, brand E-1206), acrylic acid / hydroxypropyl acrylate / 2-acrylamide-2-methylpropylsulfonic acid copolymerization (purchased from Taihe Water Treatment Co., Ltd., Shandong Province, brand TH-613) 3.9g, add 70kg deionized water, stir to make it fully dissolved, add deionized water until the solution weight is 100kg, and adjust the pH value to 11.4 with NaOH , to obtain cleaning solution L3.

[0066] The reverse osmosis membrane in the two-stage two-stage reverse osmosis system was cleaned according to the method of Example 1, except that the cleaning solution L1 used in Example 1 was replaced with cleaning solution L3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com