Steeping charging machine for cigarette blade charging

A feeder and blade technology, applied in the field of new machinery, can solve the problems of no blade purification, uneven feed liquid acceptance by the blade, and unsatisfactory cigarettes, etc., and achieve high feeding accuracy, meet the requirements of continuous production technology, and facilitate operation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

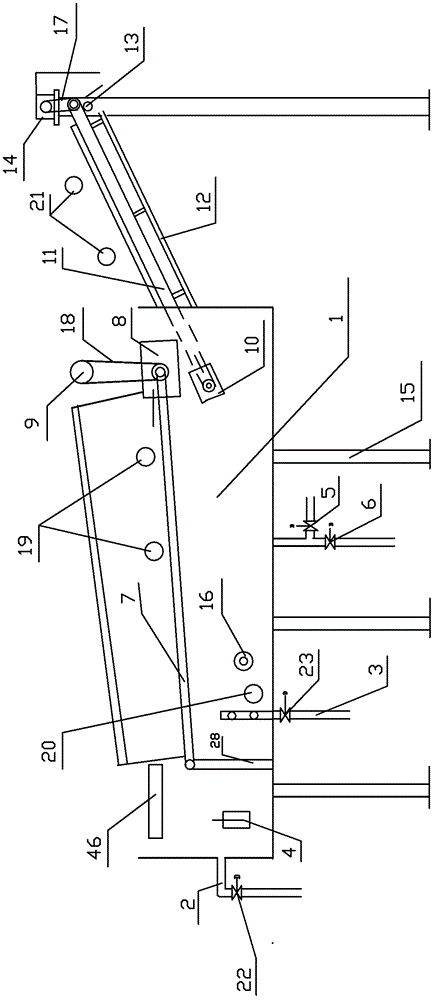

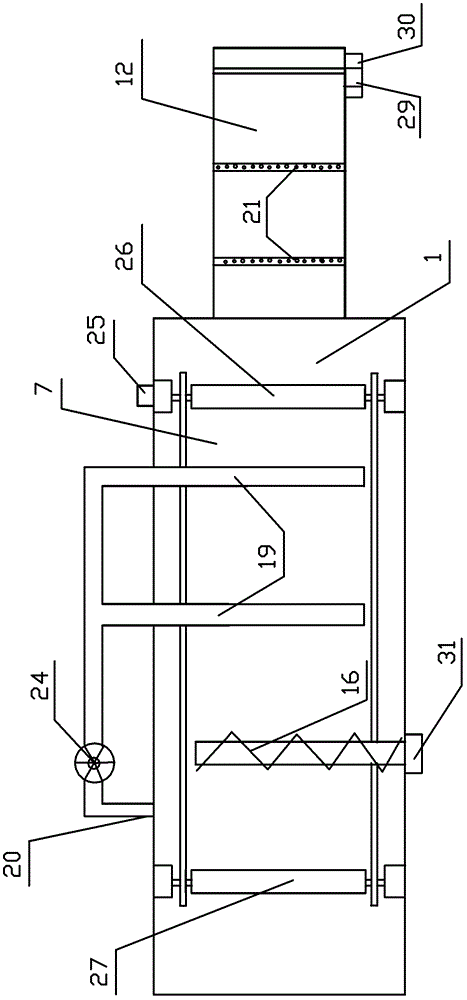

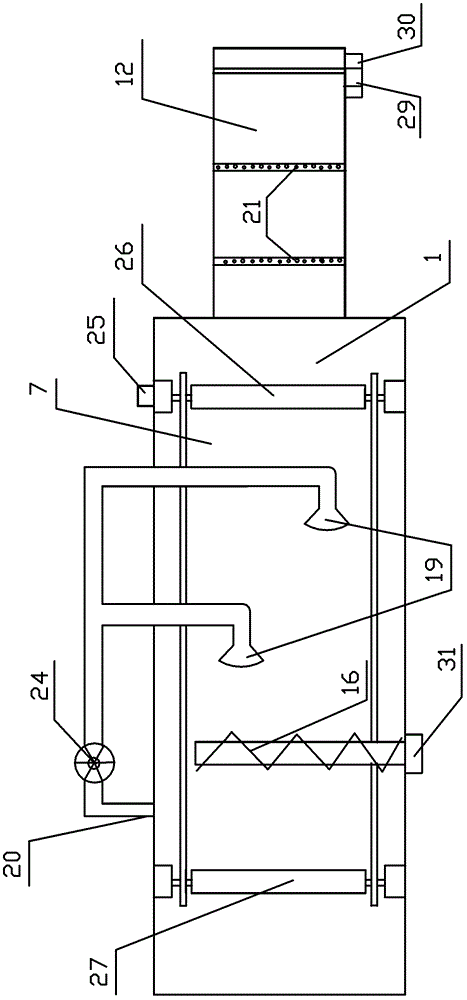

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 , 2 , Shown in 3, the impregnation feeding machine of the present invention is made of feed liquid tank 1, stirring motor 31, agitator 16, primary mesh belt conveyor 7, secondary mesh belt conveyor 11, tray 12, feed liquid circulation pump 24, Nozzle 19, air blowing pipe 21, water supply pipe 2, pneumatic ball valve 22, steam heating device 3, pneumatic film valve 23, temperature controller 4, foot 15, manual ball valve 5, 6, motor reducer 9, 14, chain Wheel 25,29,30, chain 17,18, tensioning device 8,10, and electric control system etc. are formed. The material liquid tank 1 of this machine is rectangular, except for the material liquid tank support 15 and the secondary mesh belt conveying support, the others are all made of stainless steel. The material-liquid circulation pump 24 adopts a vane pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com