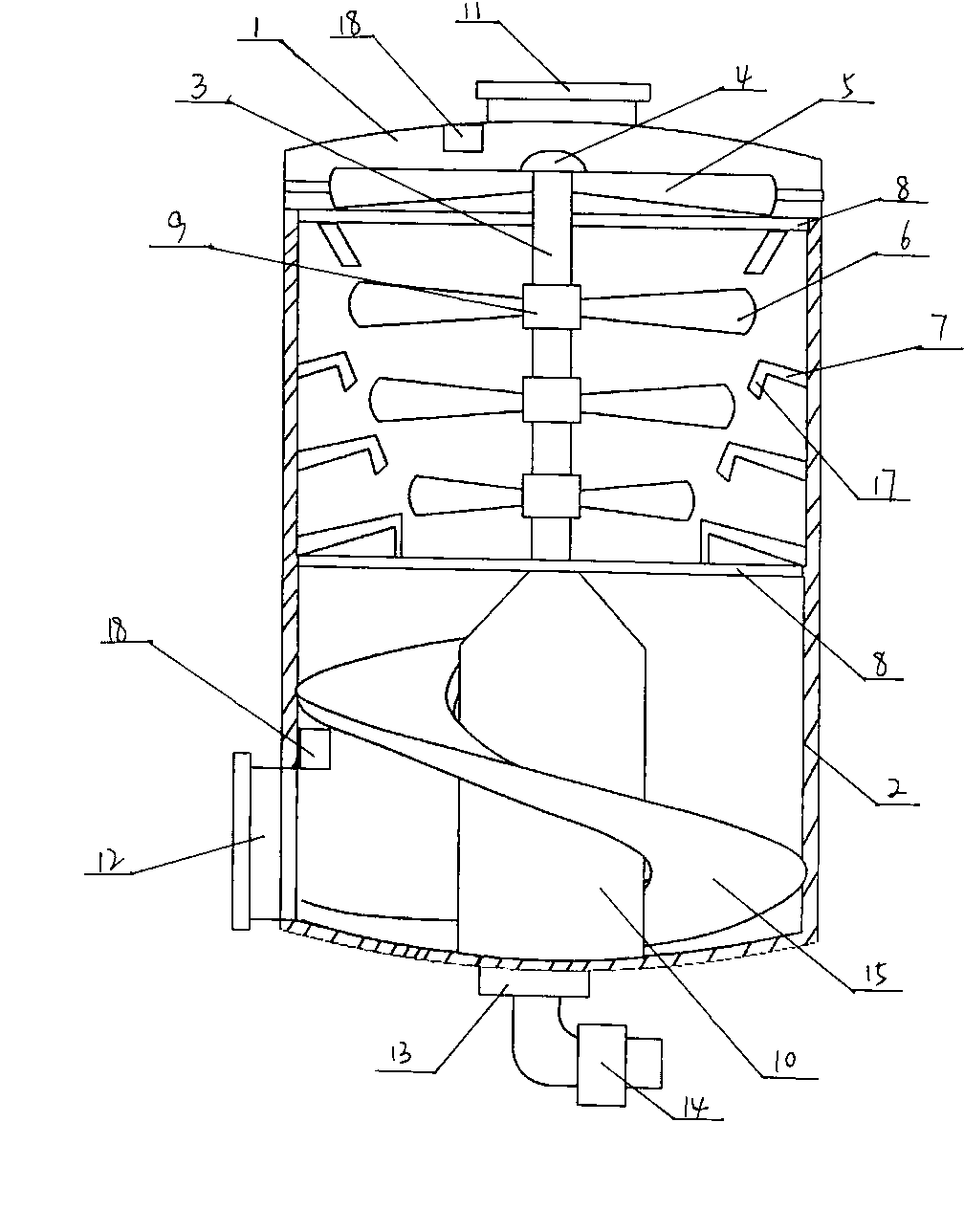

Multi-stage vortex type gas-water separator

A steam-water separator and vortex-type technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as the inability to achieve large-flow air-water separation, high pressure on the separator, and drop in air flow. Achieve small size, reduce wind resistance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

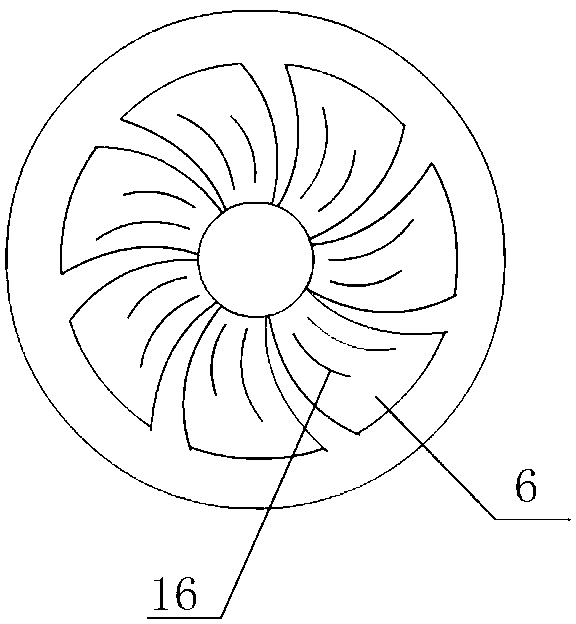

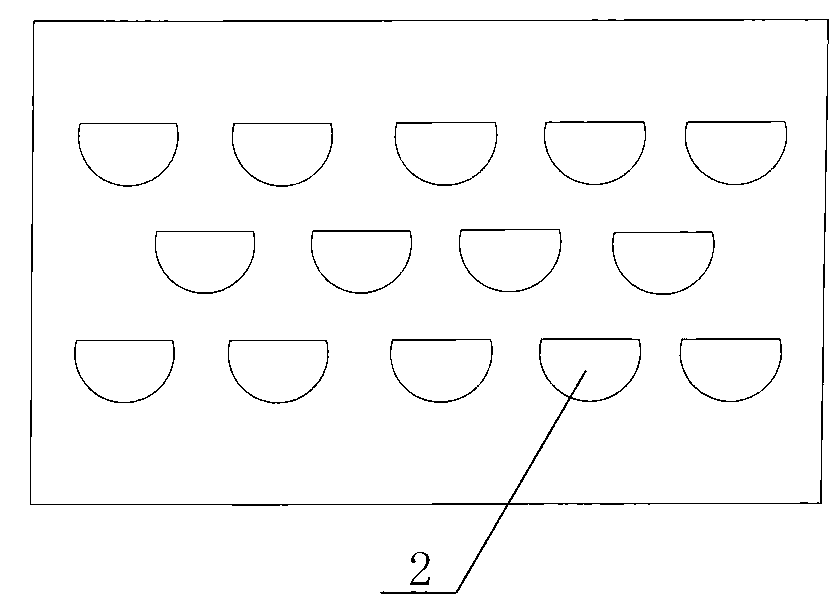

[0017] The multi-stage vortex steam-water separator includes a cylindrical shell 1, with an air inlet 11 on the top of the shell 1, an air outlet 12 on the lower side wall, and a water outlet 13 in the middle of the bottom. The self-floating valve 14 is equipped with a water-absorbing plate 2 with fish scale holes facing upwards on the inner wall of the housing, and a water-collecting chamber 19 is formed between the inner wall of the housing 1 and the water-absorbing plate 2 . A turbofan dehydration assembly and an airflow spiral guide assembly are arranged in the housing 1, wherein the turbofan dehydration assembly is composed of a central vertical shaft 3, a fairing 4, an airflow direction regulator 5, and a turbofan 6, and the airflow spiral guide assembly includes a guide Flow tube 10, spiral wind deflector 15; its specific assembly is as follows: the fairing 4 is installed directly below the air inlet 11, the airflow direction regulator 5 is installed under the fairing 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com