Milling power head of numerical-control planer type milling machine

A technology of gantry milling machine and power head, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc. Improve the walking accuracy and service life, the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

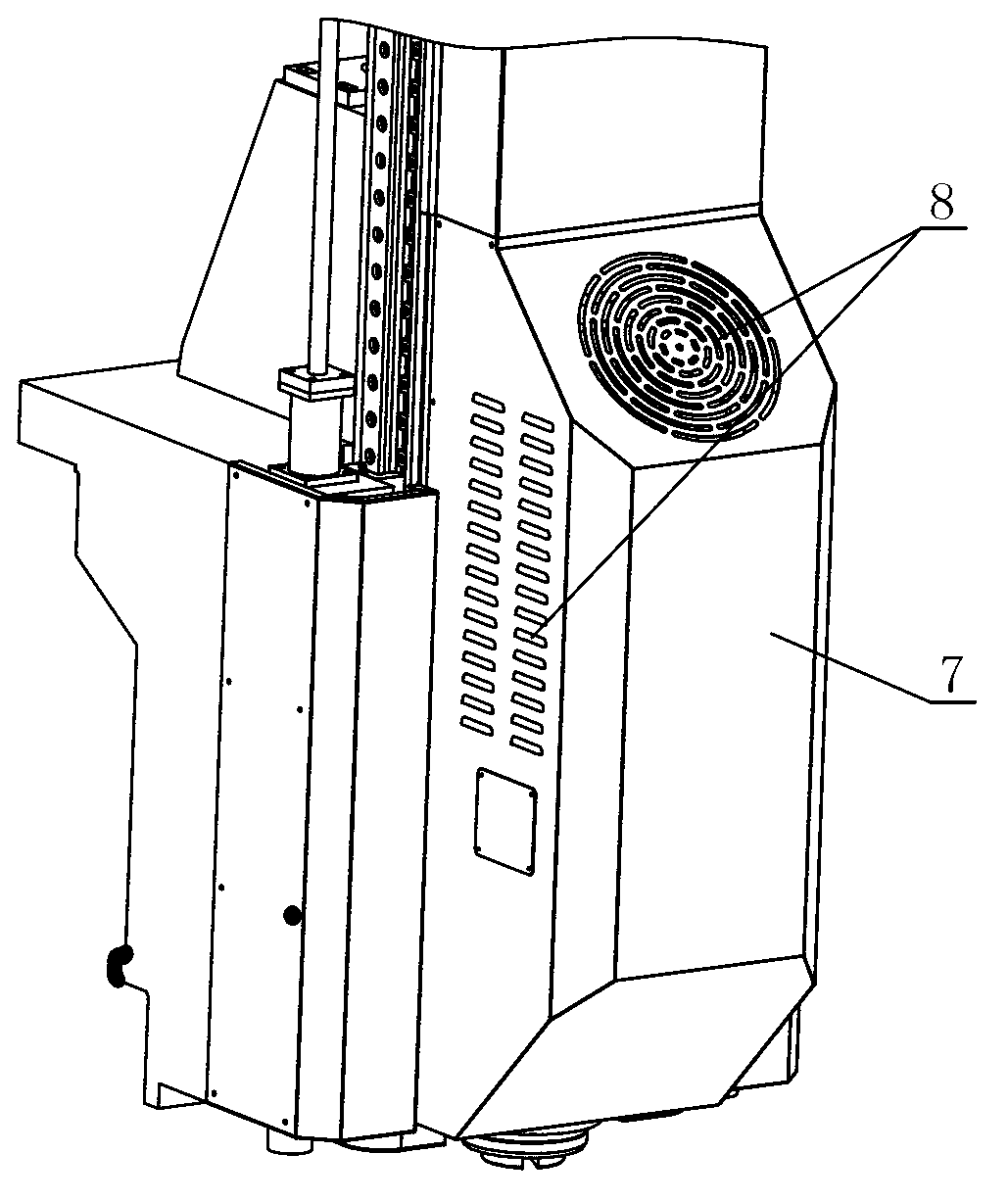

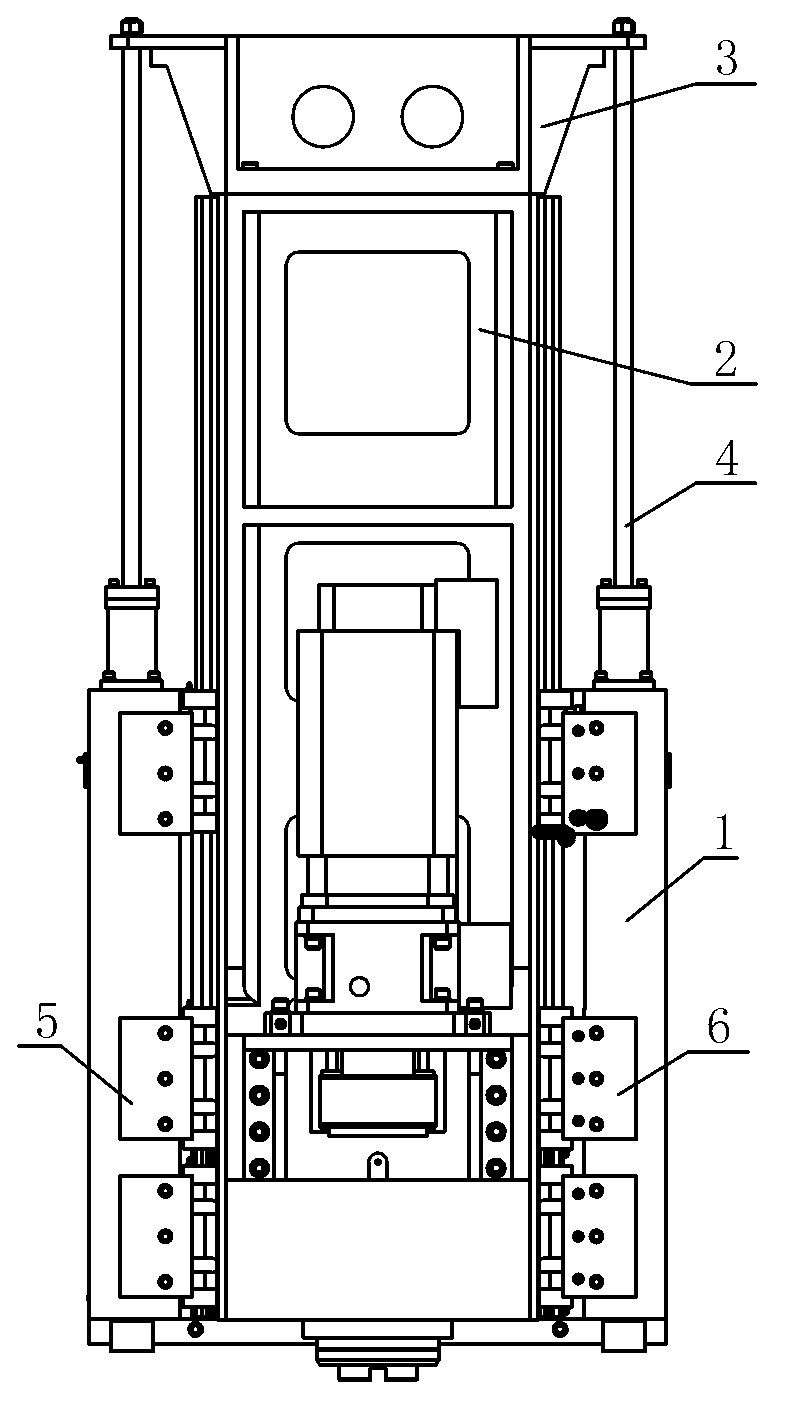

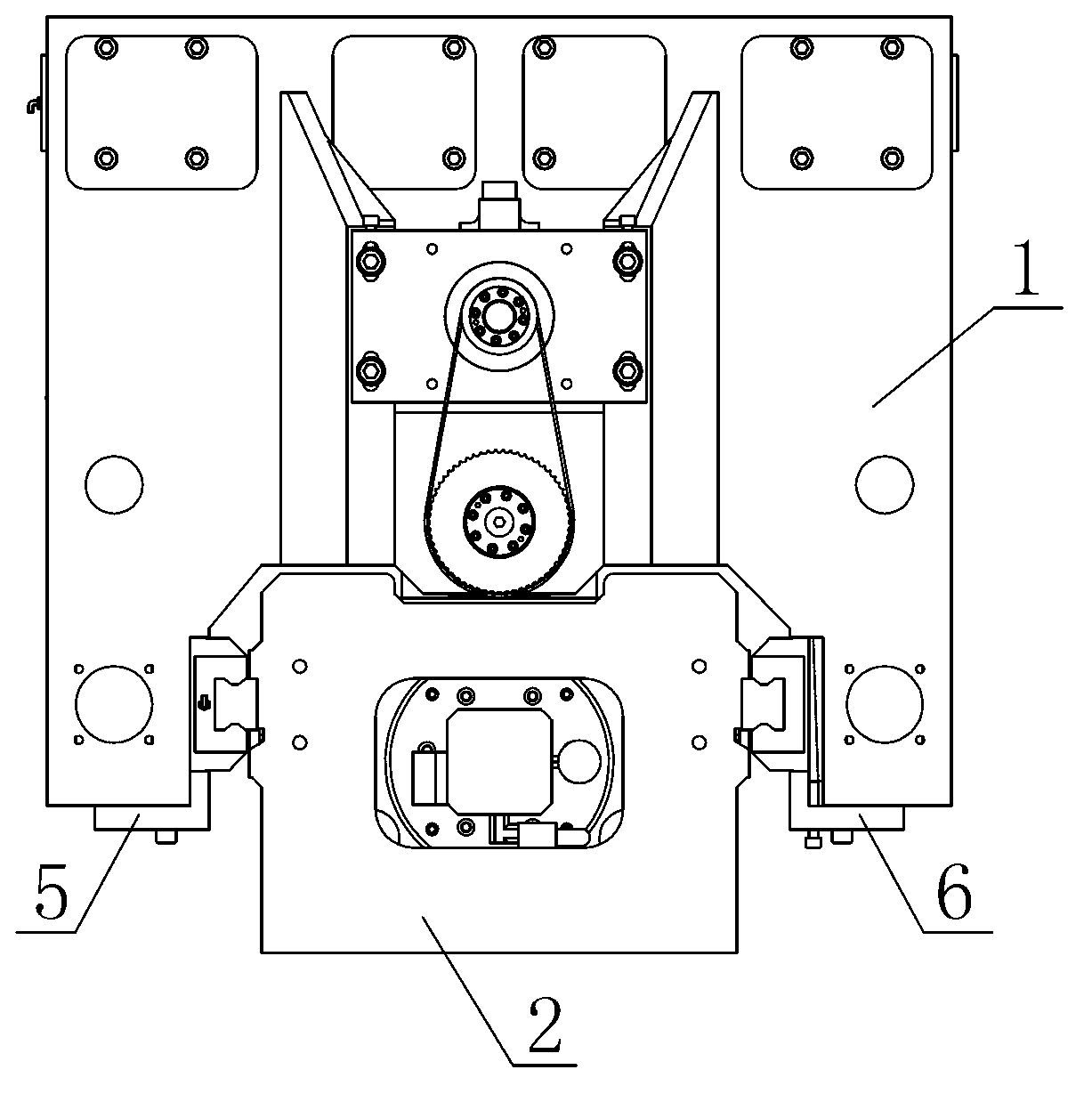

[0014] A milling power head for a CNC gantry milling machine provided by the present invention, the power head includes a sliding seat 1, a screw rod and a spindle box 2 that moves up and down along the screw rod, one side of the sliding seat 1 is provided with a groove that runs through the upper and lower sides of the sliding seat 1 , the lower part of the spindle box 2 is placed in the groove, the top of the slide seat 1 is provided with a hydraulic balance device, and the top of the spindle box 2 is linked with the hydraulic balance device.

[0015] In order to reduce the bearing axial force of the screw rod, improve the running accuracy and service life of the screw rod, make the headstock 2 move up and down flexibly, and realize strong and heavy chipping, the above-mentioned hydraulic balance device includes a buffer seat 3 and two balance oil cylinders 4, two One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com