Axial adjusting device of grooving saw for board cutting of woodworking

A technology of axial adjustment and grooving saw, which is applied in woodworking safety devices, auxiliary saw devices, wood processing appliances, etc. It can solve the problems of unstable gap, difficult processing, and large adjustment resistance, so as to avoid excessive adjustment gap , reduce unstable factors, and avoid the effect of small adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

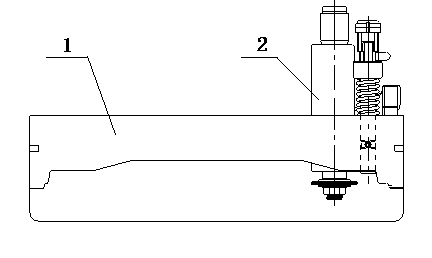

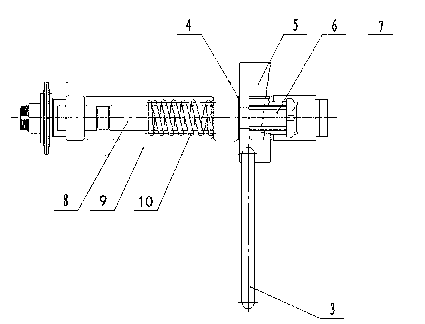

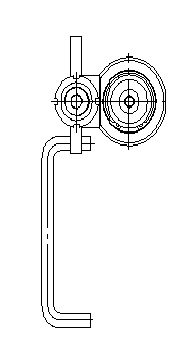

[0017] like figure 1 , 2 , A woodworking board slotting saw axial adjustment device shown in 3 and 4, including a support 1 and an adjustment mechanism 2 installed on the support 1, the adjustment mechanism 2 includes a pull rod 3, a flat washer 4, Wedge plate 5, fixed sleeve 6, lock nut 7, slotting saw fixed shaft 8, slotting saw fixing seat 9, compression spring 10, the wedge plate 5 is a plate with a chute on one side, and the pull rod 3 is installed At the lower end of the chute of the wedge-shaped plate 5; the clip spring 10, the flat washer 4, the wedge-shaped plate 5, the fixed sleeve 6, and the lock nut 7 are successively installed on the fixed shaft 8 of the slotting saw, wherein the wedge-shaped plate 5 is installed on the opening In the chute opened on the fixed shaft 8 of the slot saw, the compression spring 10 is sleeved on the fixed shaft 8 of the slot saw, with one end against the block of the support 1 and the other end against the flat gasket 4; The groove s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com