Whole hoisting craft of ship superstructure

A superstructure and overall hoisting technology, applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of dock and wharf engineering cycle impact, accident-prone, and pre-installation, etc., to improve the working environment of workers, The effect of shortening the project period and improving the pre-outfitting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

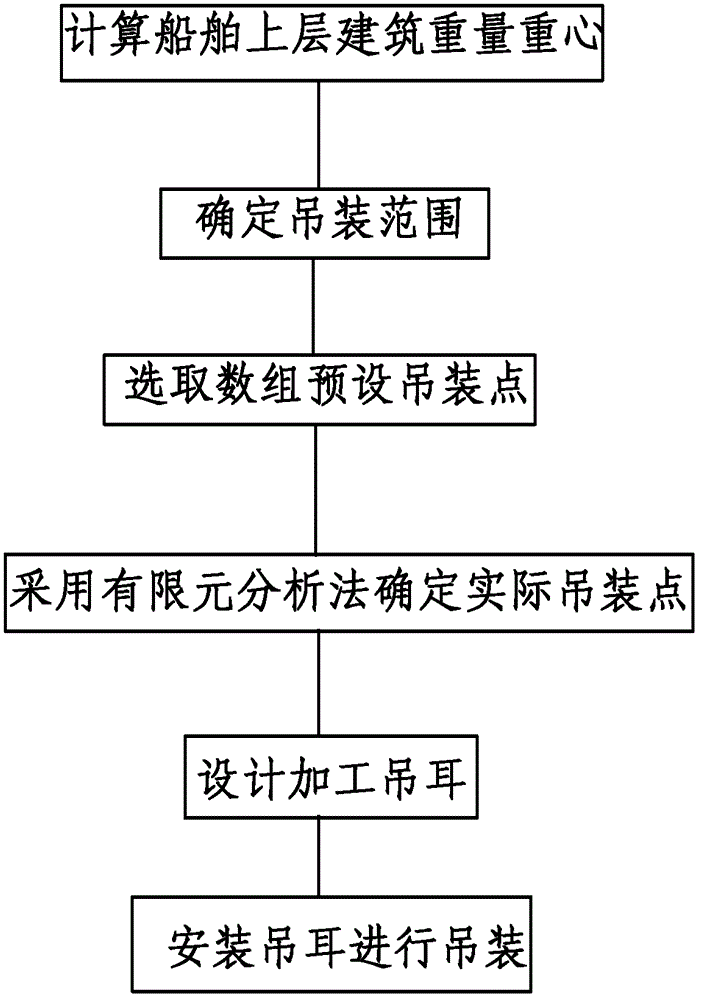

[0020] Such as figure 1 , the overall hoisting process of the ship superstructure includes the following steps:

[0021] 1) Calculate the weight center of gravity of the entire ship superstructure. The ship superstructure mainly includes hull structure, outer outfitting, inner outfitting, pipe outfitting, electrical outfitting and other parts. When calculating, the weight and center of gravity of each part can be calculated separately , and then calculate the center of gravity of the entire ship superstructure.

[0022] 2) According to the hoisting capacity and hoisting height of the hoisting device, determine the hoisting range on the superstructure of the ship, because the hoisting devices that can be installed on each ship are different, and their spans and hooking methods are also different. According to the situation to determine the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com