Woven bag automatic bottom-sewing, packing, stacking and packaging production system

A production system and packaging production line technology, which is applied to the production links of parcels, bag stacking, seam bottom of woven bags, packing, and palletizing. It can solve the problems of low production efficiency, high labor intensity of workers, waste, etc., and improve production efficiency. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

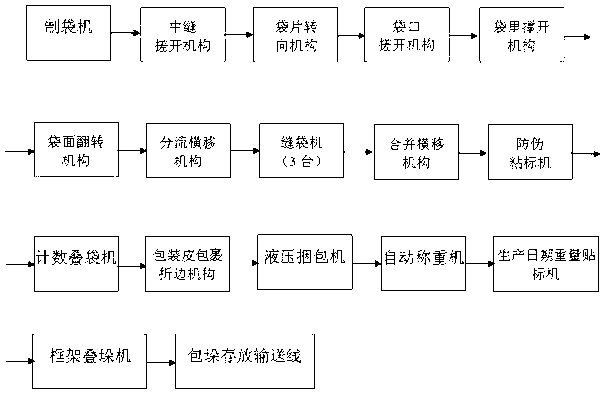

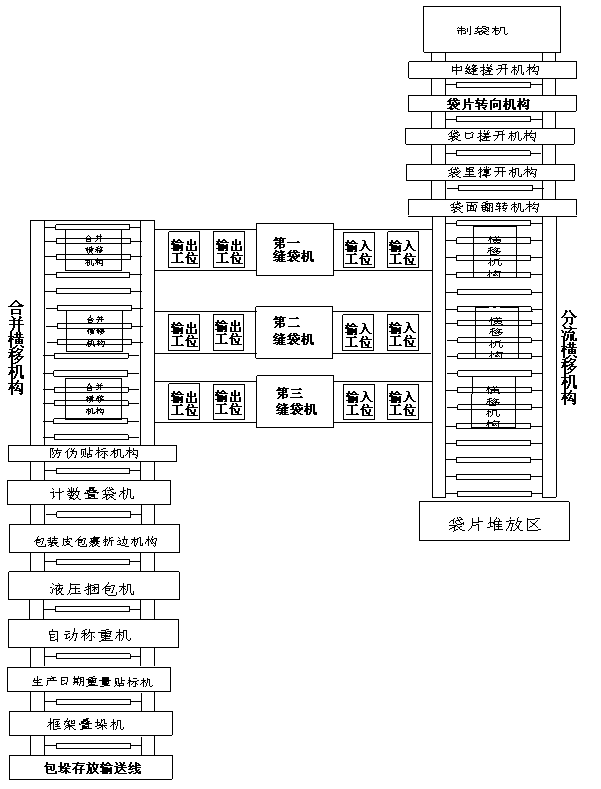

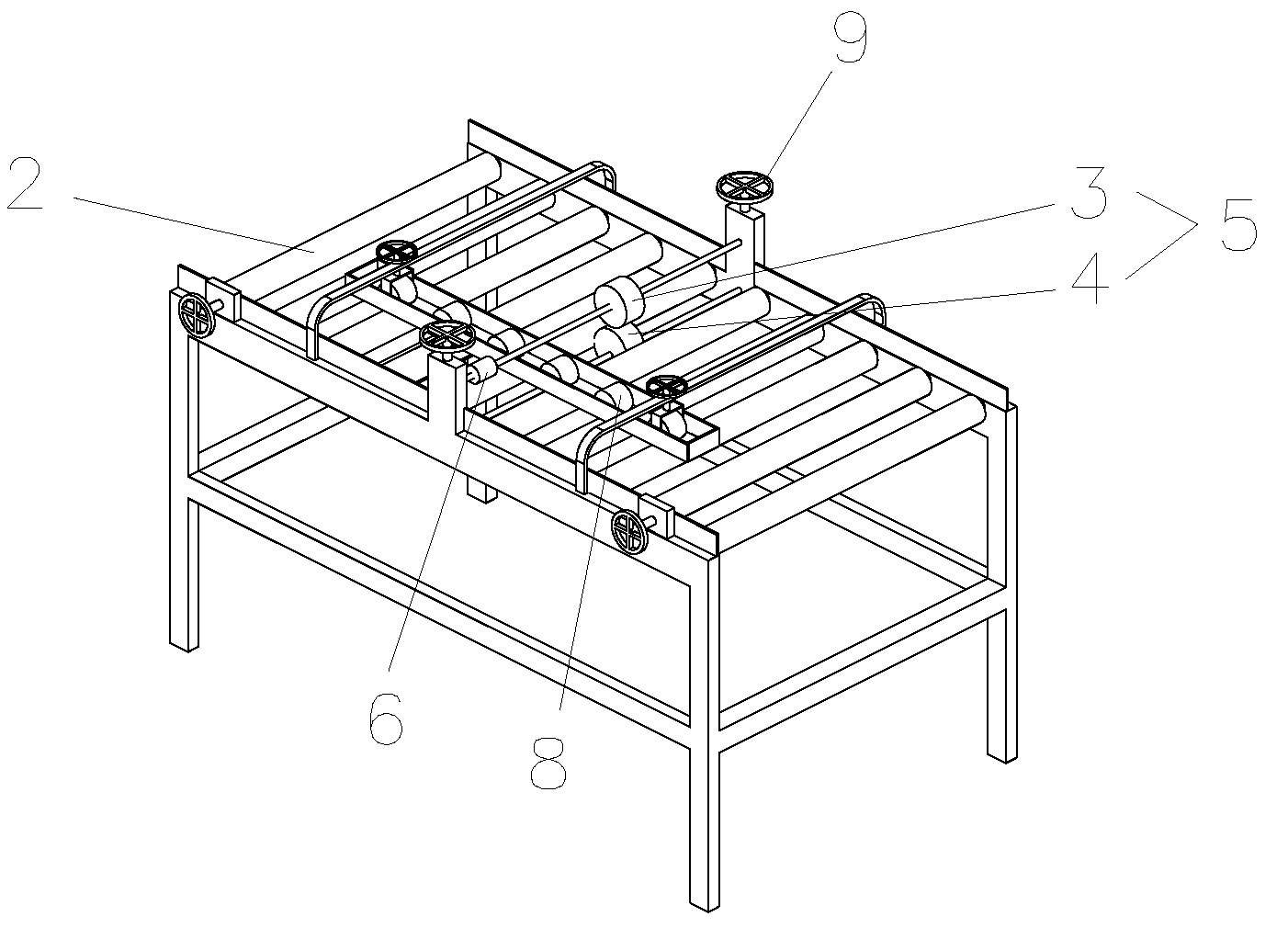

[0022] As shown in Figures 1 and 2, under the control of PLC, the woven bag automatic bottom seam packing and palletizing packaging production line, through the system's automatic identification function, execution and conveying system, automatically organizes the mechanisms of each production unit with a simple path and the fastest Accurately transport the woven bags of each link from one station to another, complete the position, time and space transfer of woven bags, ensure the production of each unit changes rapidly as needed, and ensure that the woven bags are automatically sewed and packed. Efficient operation of palletized packaging production.

[0023] According to the production plan, the operator enters the production specifications and product names on the main control panel of the conveying line and manually adjusts the width of some mechanisms. For the woven bag pieces coming out of the end of the bag making machine, the automatic control system of the conveying li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com