Automatic cigarette lifting, storing and supplying system

An automatic lifting and supplying system technology, applied in automatic control of packaging, tobacco, and cigarette manufacturing, etc., can solve problems such as blockage, extrusion deformation of cigarettes, and wrinkles of cigarettes, so as to ensure product quality, stable operation, and reduce manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

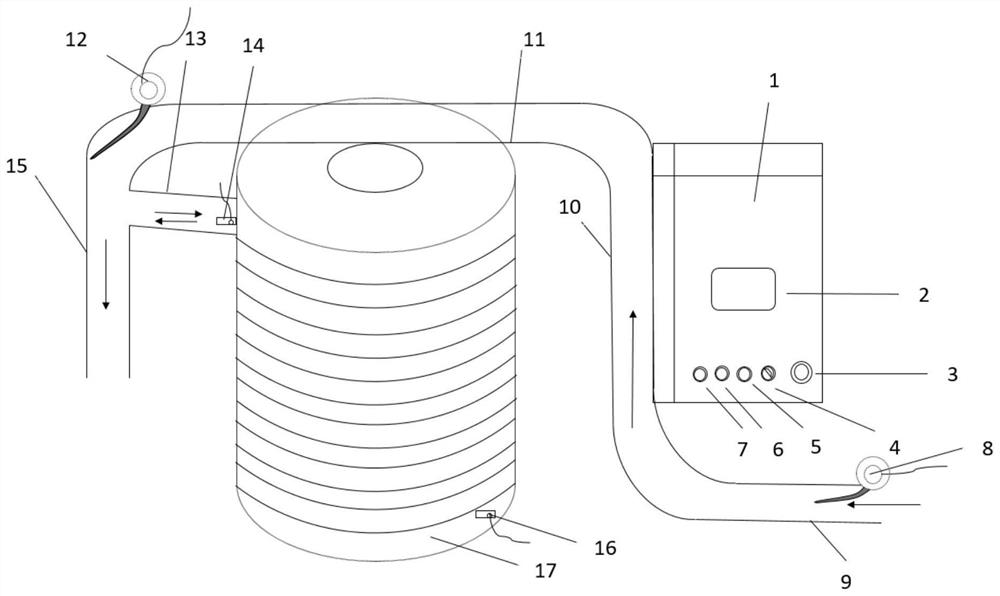

[0062] like figure 1 As shown, this embodiment provides an automatic lifting, storage and supply system for cigarettes, including a sampling toothed belt 9, a lifting toothed belt 10, a high-position conveying toothed belt 11, an oblique conveying belt 13, and a storage tank inlet detection unit 14. Descending channel 15, storage tank full detection unit 16 and storage tank;

[0063] The sampling toothed belt 9 is connected with the lifting toothed belt 10 for transporting the cigarettes from the cigarette paper outlet to the entrance of the elevator, and the lifting toothed belt 10 is connected with the high-position conveying toothed belt 11, The high-level conveying toothed belt 11 is connected to one end of the descending channel, and is used to lift the cigarettes up to the upper high-level conveying toothed belt 11, and transmit it to the descending channel. The oblique conveying belt 13 is connected to the other side of the descending channel. One end is connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com